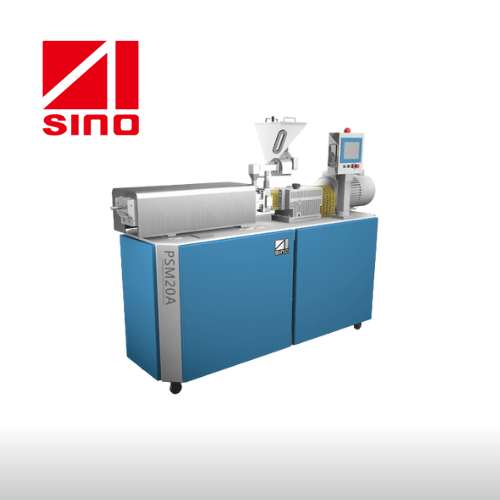

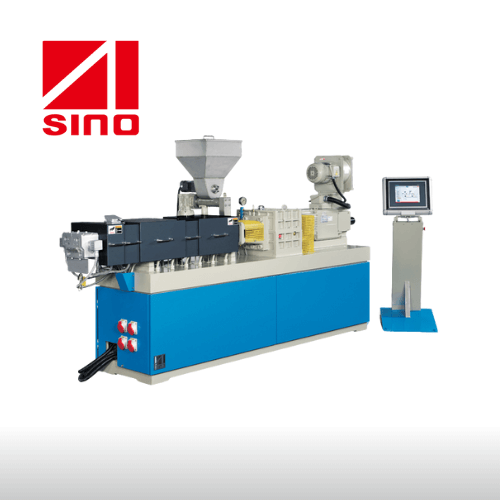

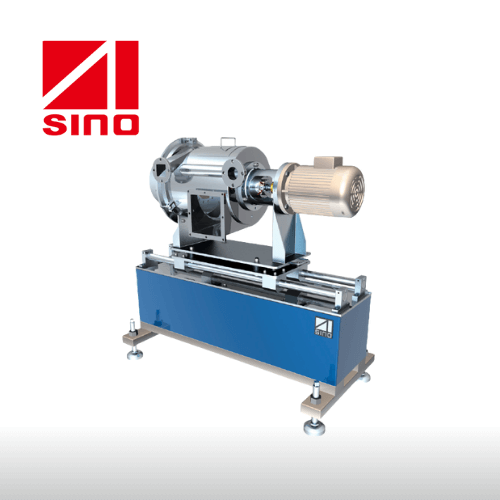

Clam-Shell Design Co-Rotating Twin Screw Extruder-PSM20A

Categories : Granulators

The PSM20A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

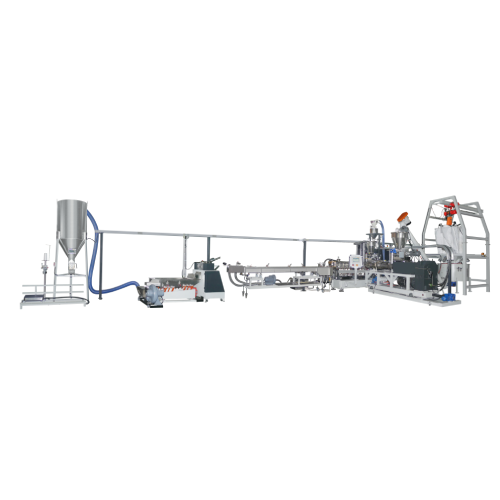

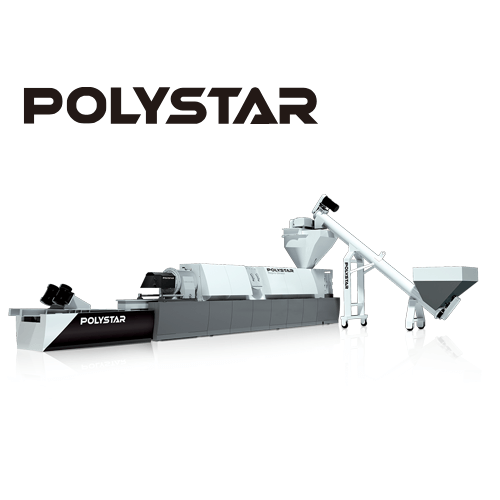

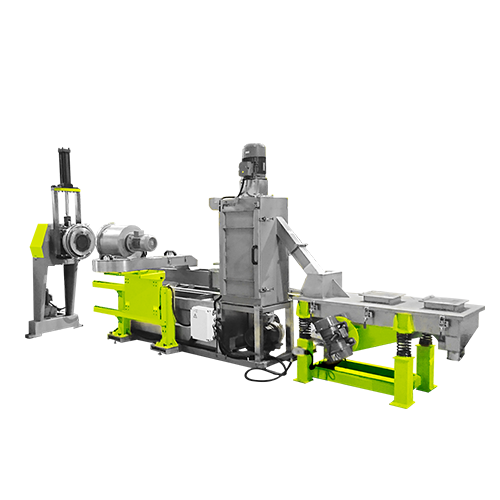

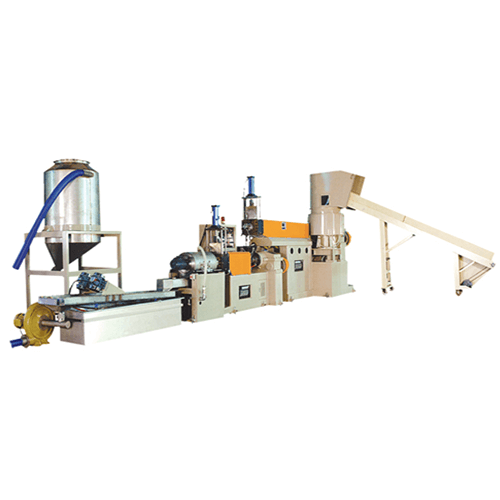

Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

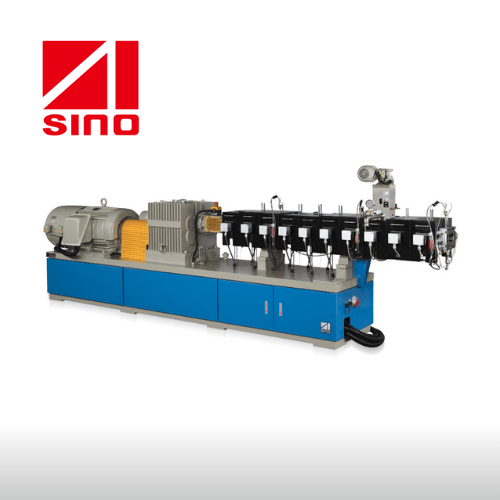

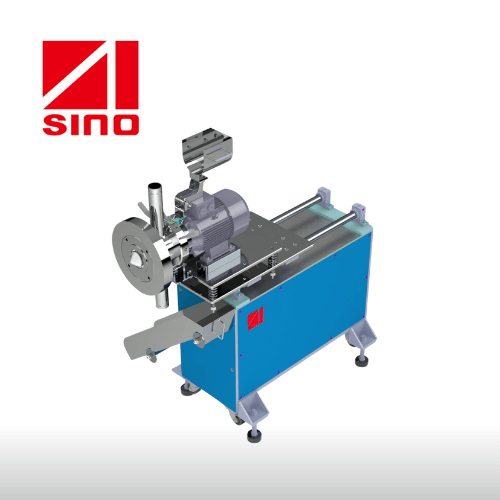

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Side Entrance Two Stages Die-Face Cutting Recycling& Pelletizing Machine

Categories : Plastic Waste Recycling Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Waste Recycling Machines

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Plastic Pelletizer Machines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost save up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Sound-proof Central Granulators - SG-43-50-70

Categories : Granulators

SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption.

Screenless Granulators - SG-14/24N/24T

Categories : Granulators

SG-14/24/24T series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials. For SG-24T series, there are two gear motors and two cutting chambers to work simultaneously. It can not only granulate the sprues and waste material, but also has an effect on long and thin or tougher sprues materials.

“Standard” Series SG-23E/30E/36E

Categories : Granulators

SG-23/30E series granulators have no significant differences with the standard model in construction and operability. The granulators feature quick blade change. They are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding and extrusion machines. Staggered blades can easily grab and granulate the materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.

Hard Plastic Recycling Machine: Repro-Direct

Categories : Plastic Waste Recycling Machines

● The Perfect Solution for recycling plastic films waste/ regrind/ granules ● Crusher and conveyor can be added and combined into a complete recycling line

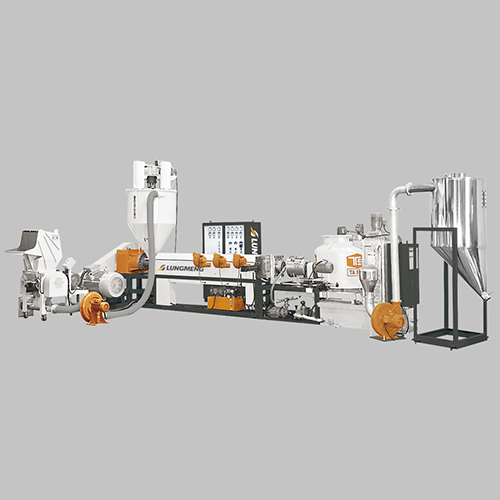

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic Pelletizer Machines

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

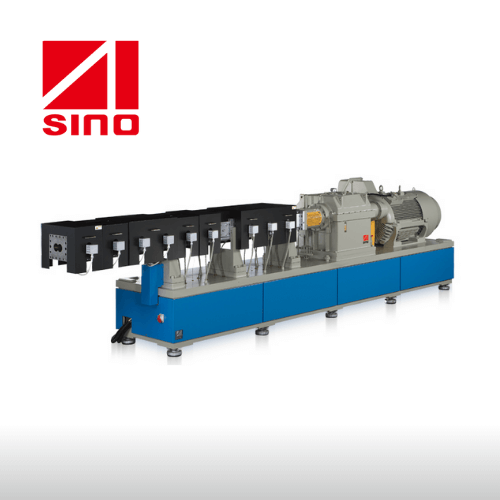

Co-Rotating Twin Screw Extruders-PSM50

Categories : Twin Screw Extruders

The optimization of the PSM50 series resulted in more efficient and durable designs. The PSM50 series has mid range production capabilities, and easy operation in reasonable price. All PSM50 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

Co-Rotating Twin Screw Extruders-PSM72A

Categories : Twin Screw Extruders

The optimization of the PSM72 series resulted in more efficient and durable designs. The PSM72 series has mid range production capabilities, and easy operation in reasonable price. All PSM72 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

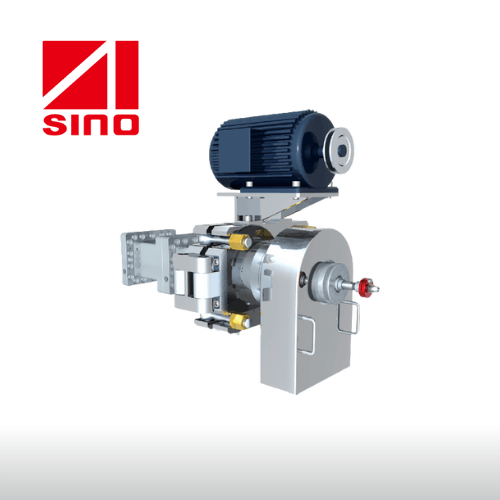

Water Ring Pelletizer-PSF

Categories : Plastic Pelletizer Machines

The PSF water-ring pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and material which may be too brittle for strand pelletizing. Variable speed cutting blade to control pellet size and surface quality. Use in line with our PSL series centrifugal dryers to complete the water-ring pelletizing system.

Underwater Pelletizer - PSQ

Categories : Plastic Pelletizer Machines

The PSQ underwater pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and sticky materials. Hot melt is extruded through a die into a water-filled cutting chamber where it is die-face cut by a high-speed cutter. The resulting spherical pellets are conveyed via water slurry to a centrifugal dryer. Use in line with our PSL series centrifugal dryers to complete the underwater pelletizing system.

Strand Pelletizer-PSH

Categories : Plastic Pelletizer Machines

The PSH strand pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Strands from the extruder are pulled through a water-filled cooling bath and blown dry by an air knife before entering the pelletizer. This simple pelletizing process is applicable to many different types of plastics and rubber. Our knives are made with tungsten carbide steel to ensure a long life and clean cuts. Puller and rotary knife can be synchronized to ensure uniform pellet size regardless of the extruder throughput. Designed with built in safety features, the moving parts are all enclosed within a protective cover.

Air Cooling Pelletizer-PSW

Categories : Plastic Pelletizer Machines

The PSW air-cooled pelletizer was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Especially good for hygroscopic materials. Variable speed cutting blade to control pellet size and surface quality. Use in line with our cyclone tanks to complete the air-cooled pelletizing system.

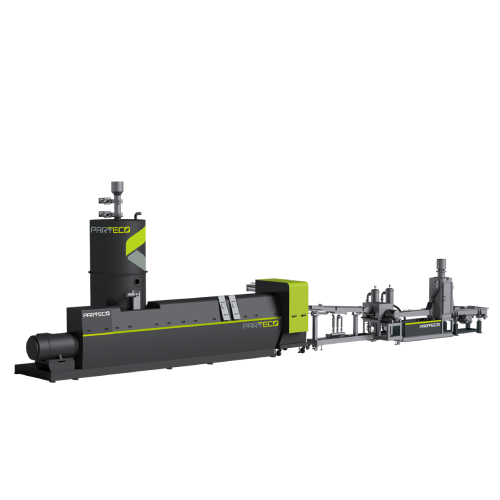

Granulating System: Strand Pelletizer

Categories : Plastic Pelletizer Machines

Advanced strand pelletizer for most plastic materials. Specialize in manufacturing of the plastic strand pelletizing system. PARTECO plastic granulating machine is applicable to most of plastic materials. Suitable for most plastic materials.

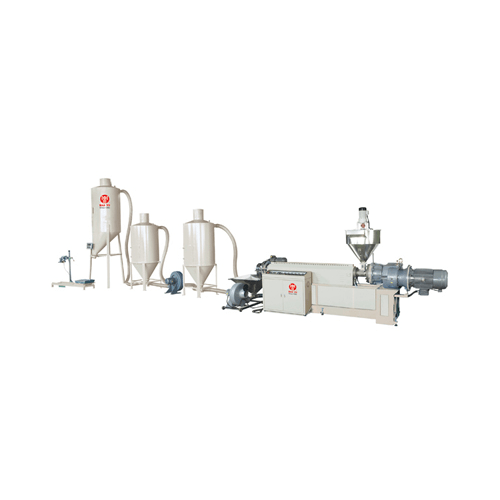

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force feeding. Able to open a input hole on top of barrel to conduct feeding formula and master batch pellets. It's a useful and productive type. Crusher is optional. With forced feeding hopper allows the machine to input two kind of material.

Granulating System: Water Ring Pelletizer System

Categories : Plastic Pelletizer Machines

Structure and function of our plastic water ring pelletizer system and machine. Features and advantages of our plastic water ring pelletizing machine line. Applicable plastic materials of our plastic granulating series system and machine. Mainly used for plastic materials such as LDPE、HDPE、PP etc.

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pelletizer Machines

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly applied to the processing of PET crushed chips recycled from PET bottles. By means of vacuum degassing system to remove the water and impurities, then go through the melting extrusion, filtering and granulating process to tailor made the complete PET recycling solutions for you. Applicable materials Film or Flakes : PET Bottle Flakes

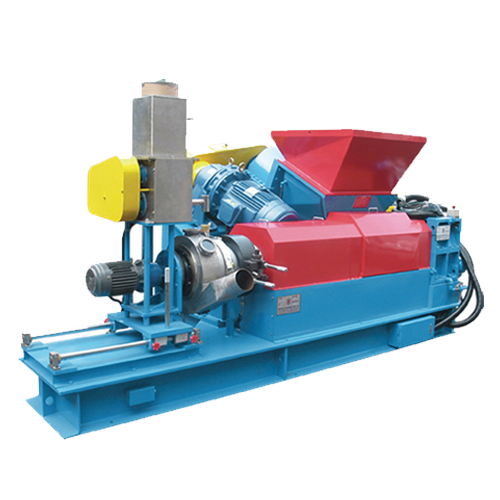

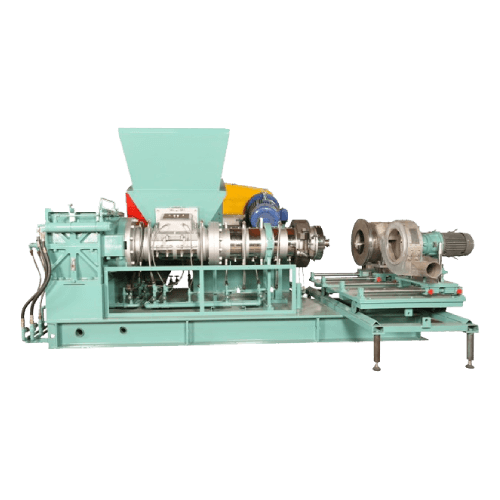

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

Extrusion & Pelletizing for Rubber、Plastic & Chemical Industries This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

Three In One Cooling Pelletizing Machine

Categories : Plastic Pelletizer Machines

Three In One Cooling Pelletizing Machine

Low-speed Granulators - SG-16N/20N

Categories : Granulators

SG-16N/20N series low-speed granulators have paddle blades and staggered blades design for customer selection. They are mainly used for granulating sprues or rejects fed by pickers or belt conveyors beside the moulding machines. They feature low speed, high torque, low noise and dust level, excellent quality and performance. Machines are built to comply with CE safety standards.

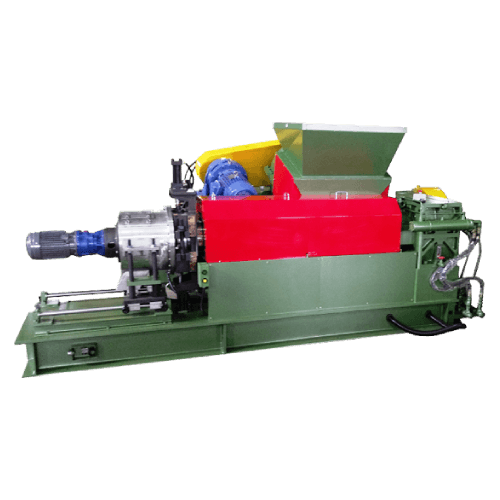

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Extruder usage for extruding and pellet producing after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind..

Pellet Extruding Machines Screws / Barrels

Categories : Screws and Barrels

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

Success Story - Cutter Compactor Plastic Recycling Machine

Categories : Plastic Waste Recycling Machines

KRIEGER-85 / Cutter Compactor Plastic Recycling Machine / LDPE Film / USA KRIEGER-125 / Cutter Compactor Plastic Recycling Machine / LDPE and HDPE Film / Indonesia KRIEGER-100 / Cutter Compactor Plastic Recycling Machine / PE Film / Vietnam KRIEGER-Z-125i / Cutter Compactor Plastic Recycling Machine / PE Foam / Korea Genius Achieves Exceptional Business Success in Cooperation with Taiwan’s PE Recycling Giant KRIEGER-150 / Cutter Compactor Plastic Recycling Machine / BOPP Film / Korea

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Plastic Pelletizer Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. More Labor-saving The feeding control system monitors the ampere and controls the feeding speed automatically. Only 1~2 operators are required for an entire plant. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatment. More tenacity and allows the materials to be fed sequence stably and also anti-bridging. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 10%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic Waste Recycling Machines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output performance. Increase the output capacity by up to 50%. Unrivaled Degassing Up to triple optional degassing zones equipped with vacuum pump. Maximize the degassing efficiency. Exhaust-Free Construct The unique development of two-stage extruder. A completely enclosed flow design, which prevents the molten polymer from releasing smoke. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs presenting a smart and reliable plant. OUTSTANDING PERFORMANCE Increase the output capacity up to 50%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. GENIUS

High-Speed Dyeing & Pelletizing Production Line

Categories : Compounding Lines

Suitable for masterbatch with fiber pelletizing, HDPE, LLDPE, LDPE, PP, PMMA, ABS, PC, Nylon, etc. Special screw design for compounding Changing material is easy Easy to operate Machine frame is very strong Customized screen changer