Servo Power-Saving Injection Molding Machine (HT Series)

Categories : Energy Saving Injection Molding Machine

It is standard and conventional equipment. The applicable industries include general household hardware products, electronic device housings, such as multifunction printer, laser printer or compute...

Heavy Duty Double Toggle Injection Molding Machine

Categories : Energy Saving Injection Molding Machine

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision...

All Electric Machine With SPARK Series

Categories : Energy Saving Injection Molding Machine

Features: Combining ultra-thin high speed and ultra-thick low speed Revolution round template design with Japanese super rigid frame Super high-speed intelligent computer controller With ...

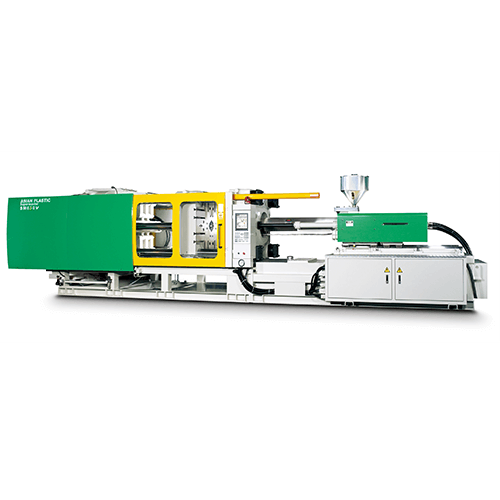

Double Toggle Injection Molding Machine (SMV Series)

Categories : Energy Saving Injection Molding Machine

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Mul...