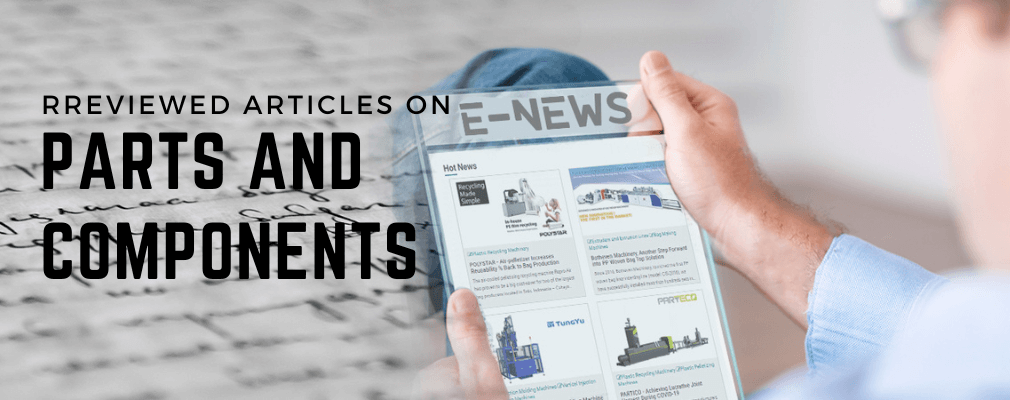

Stabilizer

Categories : Blown Film Extruder Parts

The wires of stabilizing ring with SUS304 for increased. Easy to adjust. Single or double layer assemble easily. Mass production, competitive prices. Choice of various ring diameters. Blown Film E...

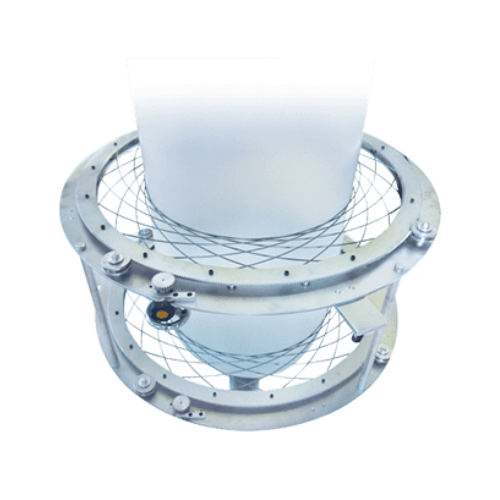

Back to Back Blown Film Winder

Categories : Blown Film Extruder Parts

Back to Back Blown Film Winder is constitute with two stations that back to each other. Typically, it combines two winding stations with familiar machine functions into a complete set. With the var...

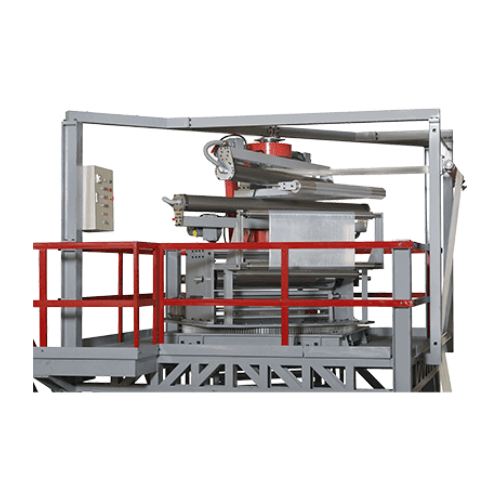

Bubble Cage by Motor Control

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the D...

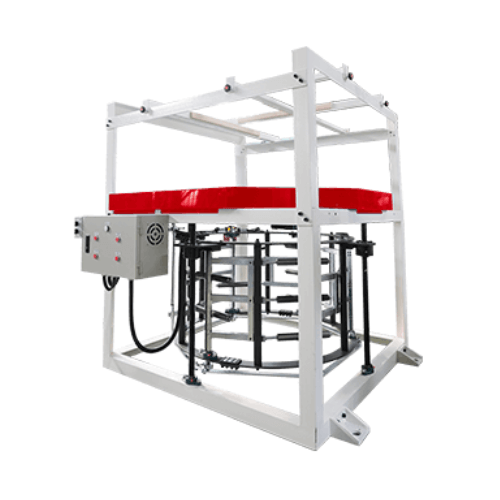

Horizontal Oscillating Haul-Off System

Categories : Blown Film Extruder Parts

HSIN LONG Horizontal Oscillating Haul Off apply to different Plastic Film Blowing Machines such as Single Layer, Multi-Layers, and Co-Extrusion. The main function of it is to distribute any uneven...

Blown Film Take-Up Unit

Categories : Blown Film Extruder Parts

HSIN LONG Setting in the highest part of Plastic Film Blowing Machine, the most classic type of Take-Up Unit is suit for most Blown Film Machines. Different with the Oscillating Haul-Off, the volu...

Single Manual Blown Film Winder

Categories : Blown Film Extruder Parts

The classic Manual Blown Film Winder is the basic and most economical type. For the use of manual type, it is more suitable for film width which is not that wide since it needs to use manual operat...

ABA Blown Film Extruders

Categories : Blown Film Extruder Parts

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. Eterlong supply customized machine specifications for different output, material, f...

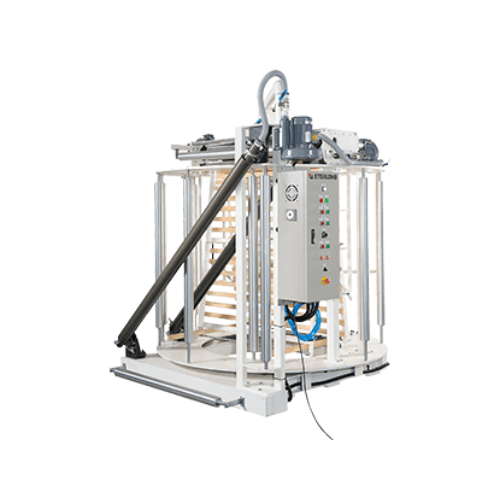

Double Vertical Blown Film Winder

Categories : Blown Film Extruder Parts

For those customers with spaces problems, the Double Vertical Film Winder will be the best choice since the volume of it does not take up space. Due to the special design, the up-side and down-side...

Vertical Oscillating Haul-Off System

Categories : Blown Film Extruder Parts

HSIN LONG The main function of Vertical Oscillating Haul Off System is to distribute the uneven variations uniformly in order to make the film averagely. Different with the horizontal one, the nip...

Blown Film Bubble Cage/Basket

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the D...