Cutting Piece Machine (YSW-CP)

Categories : Foam Cutting Machines

• This machine provides slitting and cutting functions. • Finished product can be collected by row needs, and the operator simply needs to unload it.

Automatic Feeding Precision Cutting Machine SCM-60

Categories : Foam Cutting Machines

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks.

Multi-layer Automatic Feed Cutting Machine SC-310

Categories : Foam Cutting Machines

Performs the pressurization with double output axle to provide powerful and stabilized pressurizing capacity.

Automatic Feeding Precision Cutting Machine (roll-to-roll) SCM-65-SP

Categories : Foam Cutting Machines

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks.

Precision Hydraulic Double-Sided Auto Feed Cutter HC-155

Categories : Foam Cutting Machines

Bother double-side and single-side operation, time and manpower saving, one machine for two purposes to give excellent effect of production.

Automatic Feeding Precision Cutting Machine SCM-65

Categories : Foam Cutting Machines

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks.

Precision Hydraulic Automatic Die-cutting Machine/4 columns Type SC-550

Categories : Foam Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

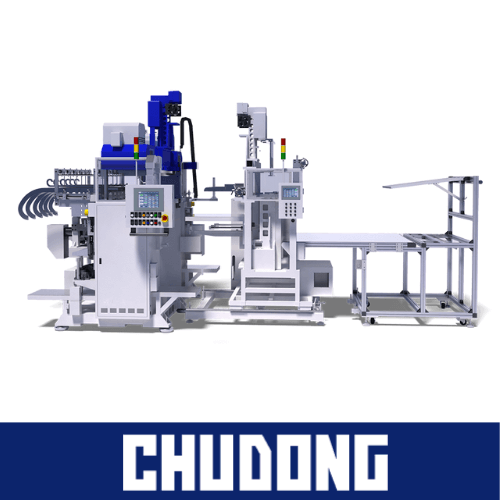

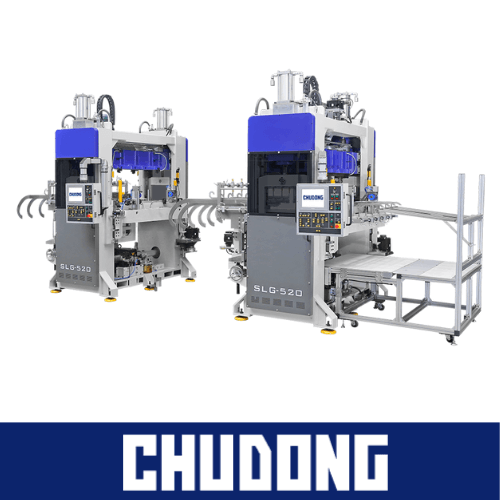

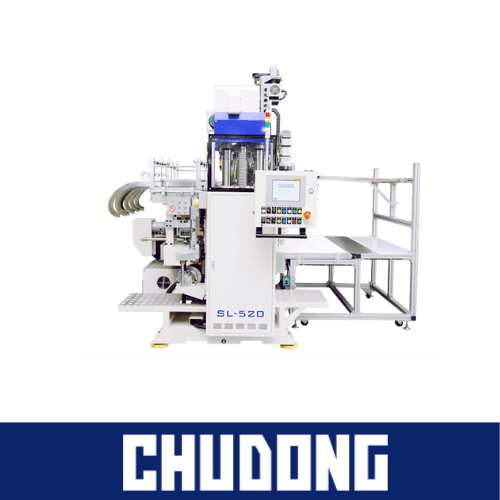

Vertical Trimming Press SL-520

Categories : Foam Cutting Machines

Perfect Integration Of Innovation And Convention

High-accuracy Multi-function Hydraulic Cutting Machine SC-650

Categories : Foam Cutting Machines

The machine body has been machined for several finishing processes in creating low-profile variable high-rigid machine body.

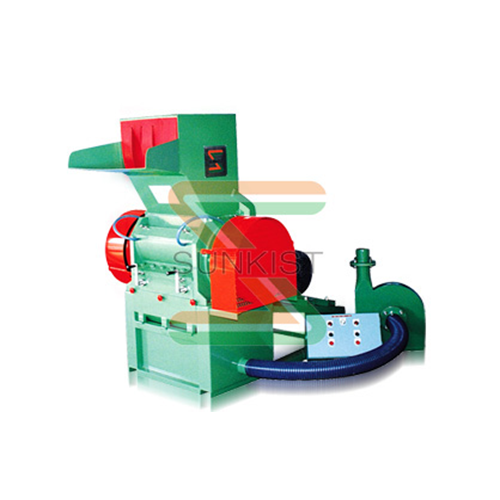

Super Power Breaker And Crusher

Categories : Foam Chipping Machines

For high capacity to cut foam waste into small chips.

Precision High Speed Hydraulic Automation Cutters-CSS-202

Categories : Foam Cutting Machines

● The machine adopts two-hand button, safe operation, fast, smooth, strong pressure, no noise, no vibration power, upstairs, downstairs plant can be used, low failure rate, improve production effic...

AUTOMATIC FEEDING PRECISION CUTTING MACHINE (ROLL-TO-ROLL) APL-500SP

Categories : Foam Cutting Machines

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with liner rail desi...

HIGH-ACCURACY ROLL-TO-ROLL AUTOMATIC FEED CUTTING MACHINE TRC-350SP

Categories : Foam Cutting Machines

Double-Axle Synchronous Feed Mechanism: Enhances the production speed and Yield Rate through double-axle synchronous feeding. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Uses th...

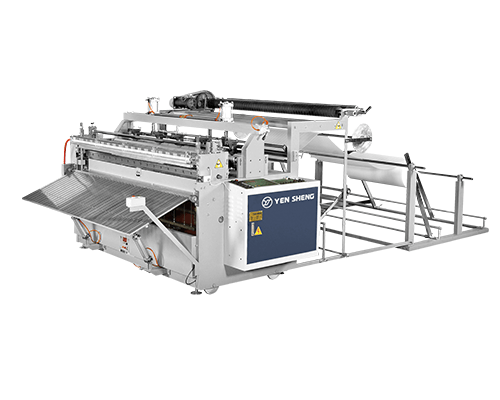

Long Sheet Cutter (Conveyor Type) With Two Side Trimming Device, Platform And Winding Device

Categories : Foam Cutting Machines

It is specially designed for cutting flexible long block into thin sheet and winding foam into roll for quilting or laminating purpose.

Foam Sheet Extrusion Line

Categories : Foaming Machinery

Foam Sheet Extrusion Line Features : With proper mixing of melted resin & blowing agent, provides most homogeneous mixing. Accurate blowing agent injecting quantity and temperature control t...

H Type Chipping Machine

Categories : Foam Chipping Machines

For chipping all kinds PU foam waste and quilting mattress cover waste. The SA-4A chipping machine is suitable for chipping all kinds of flexible PU foam waste, such as hr molding as well as the m...

XPS Extrusion Line

Categories : Foaming Machinery

XPS Extrusion Line Features : With proper mixing of melted resin & blowing agent, provides most homogeneous mixing. Accurate blowing agent injecting quantity and temperature control to stabilize...

Auto Circular Horizontal Cutting Machine

Categories : Foam Cutting Machines

For cutting Flexible PU foam block with density under 50kg/m3, rebonded foam with density under 80kg/m3 and open celled PVC foam.

Auto Contour Cutting Machine

Categories : Foam Cutting Machines

The contour of shaped parts which will be cut are programmed by using a professional computer which includes standard accessories CPU: Celeron 2.5 G SDRAM: 256 MB HDD: 80 G DVD BURNER 19” LCD...

Heavy Duty Horizontal Splitting Machine With Quad Side Trimming And Auto Stacking Device (Conveyor Type)

Categories : Foam Cutting Machines

The machine with quad side trimming and auto stacking device is a heavy duty horizontal cutting machine which cuts high density foam block into thin sheets. Suitable for cutting Natural & Synth...

High-accuracy Mini-sized Automatic Cutting Machine-APL-300

Categories : Foam Cutting Machines

●Well-designed and Stabilized Bottom Dead-point Accuracy: Specially designed machine structure and basic machining method, which provides extremely high cutting accuracy and stability. ●User Frie...