Automatic Injection Molding Machine

Automatic injection molding machines use computer-controlled hydraulic or servo systems to melt and inject plastic into molds, enabling fast, high-precision, and repeatable production of parts and casings. Ideal for high-volume, stable manufacturing in automotive, electronics, appliances, 3C, and construction industries.

PRM-Taiwan offers various machine types including BMC Injection Molding Machines for thermoset materials, Energy Saving Injection Molding Machines, and Gas Assisted Injection Molding, helping businesses achieve high efficiency and smart production goals.

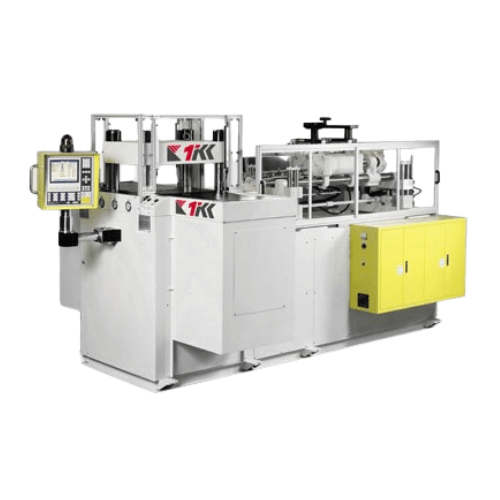

BMC Injection Molding Machine (BMC Series)

Categories : BMC Injection Molding Machine

It is BMC injection molding equipment, which is suitable for automotive parts, electronics industry, home appliances, housing and parts of communication equipment.

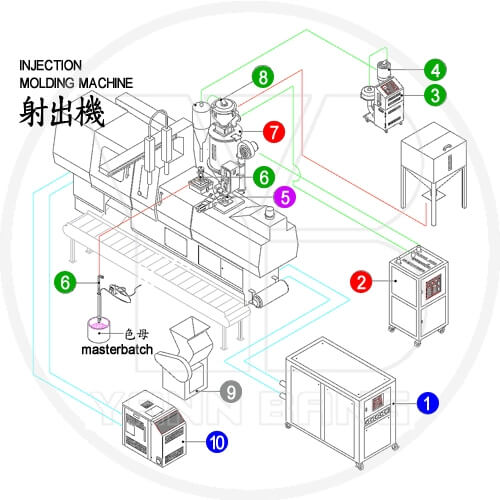

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Automatic Injection Molding Machine

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperat...

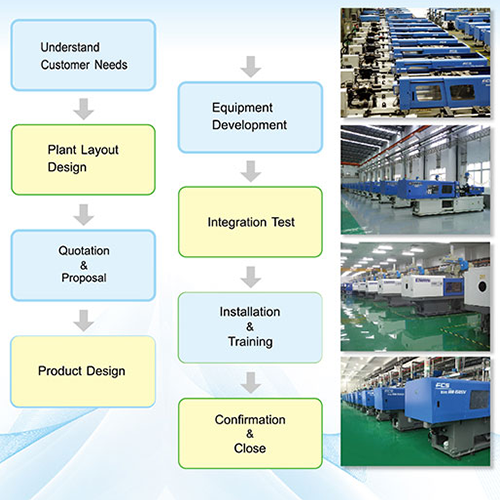

Turnkey Solution Service

Categories : Automatic Injection Molding Machine

Customers’satisfaction is always our main goal at FCS. We value customer’s satisfaction feedback as a guide to improve our service policies. Our service is available throughout the worl...

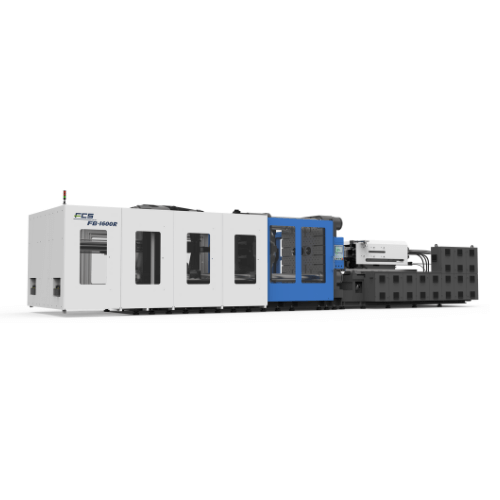

Sandwich / Interval Injection Molding Machine (FB-C Series)

Categories : Automatic Injection Molding Machine

It is sandwich/interval injection molding equipment, which is suitable for producing two-component sandwich, interval, pattern and other products.

Gas Assisted Injection Molding System

Categories : Gas Assisted Injection Molding

-With touch panel & graphic display for monitoring pressure within the mold. -5 Stages of air pressure of and flow control. -Closed-loop pressure control from 25~300 kg/cm2; response time is le...

Special Purpose Machine KVH (STANDARD)

Categories : Automatic Injection Molding Machine

With automatic inserting equipment, adopt optical sensor and vacuum testing.....

Large Rotary Table Two-Component Injection Molding Machine (FB-R Series)

Categories : Automatic Injection Molding Machine

It is large rotary table two-component injection molding machine. It is suitable for two-component and multi-component products, including automotive light and home appliance… etc. With its ...

Rotary Table Two-Component Injection Molding Machine (FB-R Series)

Categories : Automatic Injection Molding Machine

It is rotary table two-component injection molding equipment. It is suitable for two-component and multi-component products, including automotive lamp housing, livelihood supplies, etc. FCS

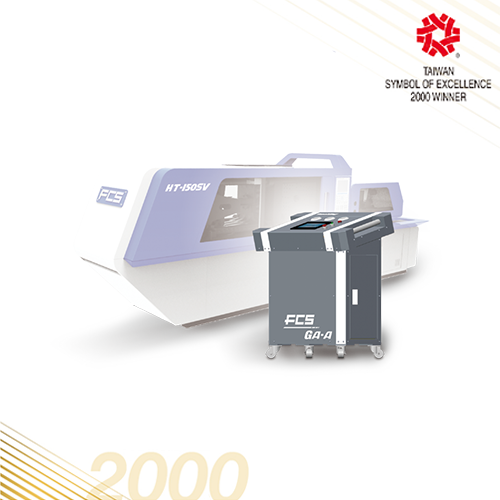

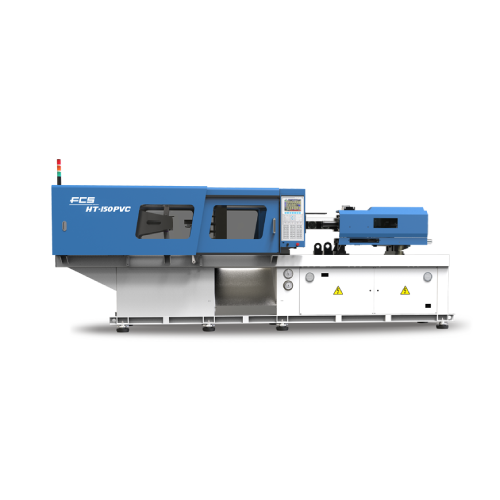

Servo Power-Saving Injection Molding Machine (HT Series)

Categories : Energy Saving Injection Molding Machine

It is standard and conventional equipment. The applicable industries include general household hardware products, electronic device housings, such as multifunction printer, laser printer or compute...

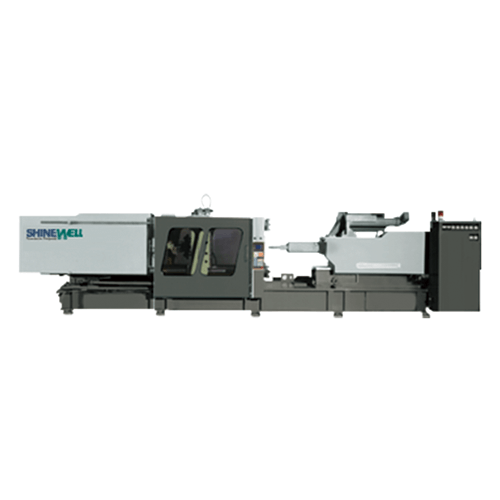

PVC Pipe Fitting Injection Molding Machine

Categories : Automatic Injection Molding Machine

The PVC injection molding machine is for producing PVC pipe fittings used in building and construction industries, such as pvc socket, pvc tee, pvc elbow, pvc coupler, and pvc valve.

ATOP- Horizontal Plunger Type Injection Molding Machine

Categories : Automatic Injection Molding Machine

● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save runner resin. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radia...

DG-P Series Special-Purpose Pet Injection Molding Machine

Categories : Automatic Injection Molding Machine

Recently, PET material is used greatly on producing containers, and gradually substitutes PP, PE, PVC material. Due to the characteristic of PET, the screw design is different from general. Besides...

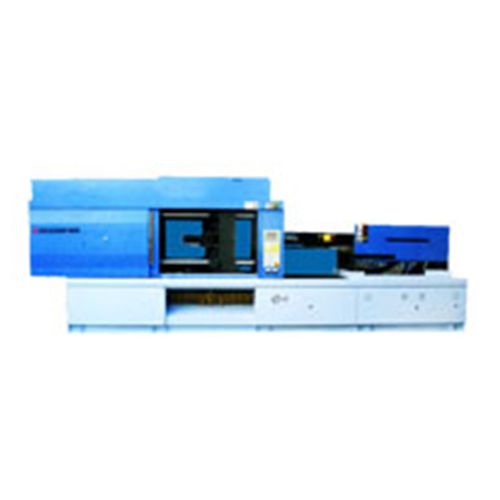

Double Toggle Injection Molding Machine (SMV Series)

Categories : Energy Saving Injection Molding Machine

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Mul...

Toggle Injection Molding Machine SW-90B to SW-570B

Categories : Automatic Injection Molding Machine

STANDARD EQUIPMENT & ACCESSORY FOR SW-B SERIES ● Hydraulic device and electrical control for core puller and unscrewing ● Automatic mold height adjustment ● Automatic oil lubricator ● Air eject...

Toggle Inward Injection Molding Machine CNT Series

Categories : Automatic Injection Molding Machine

Plastic (toggle inward) injection molding machines are new invented products that have higher standards in performance, more flexibility and more efficiency than traditional. Also, in order to cate...

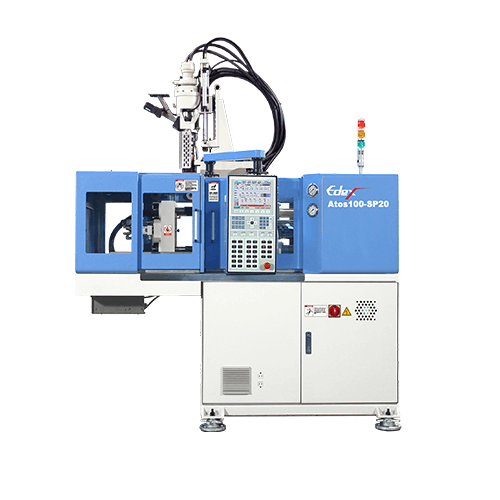

Atos- Horizontal Parting Line Plunger Type Injection Molding Machine

Categories : Automatic Injection Molding Machine

● Without the sprue, it saves a lot runner resin weight. ● Produce precise micro injection products. ● Products with multi cavities can be highly concentrated to the center. ● 2-platen 4-cylinde...

DG-B Series Special-Purpose Bmc Injection Molding Machine

Categories : Automatic Injection Molding Machine

BMC is material mixed by unsaturated polyester, filling agent, coloring agent, releasing agent, catalytic agent and glass fiber. Not only with excellent heat- resistant, mechanic character, electr...

Atom- Horizontal Plunger Type Micro Injection Molding Machine

Categories : Automatic Injection Molding Machine

● The best choice in micro injection products. ● New design patent-IPIS (Interchangeable Plunger Injection System). ● Plunger Type Injection can highly save runner resin. ● 2-platen 4-cylinder d...

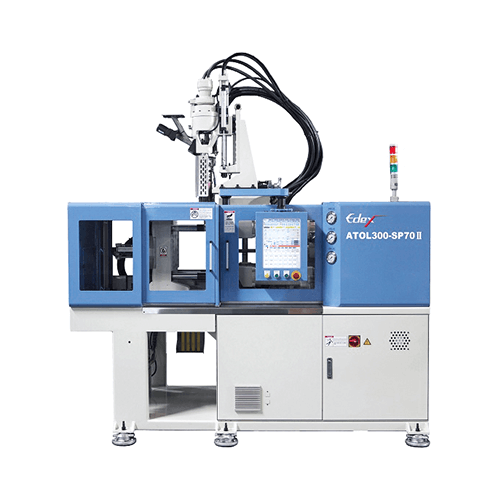

ATOL- Horizontal Multi-color/resin Injection Molding Machine

Categories : Automatic Injection Molding Machine

● Single, dual, triple color/resin in one machine. ● Suits for Plunger type injection or screw type injection system. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial plat...

BMC Injection Molding Machine - 300BMC to 850BMC

Categories : Automatic Injection Molding Machine

Common commissioning for molding products such as electric parts and auto headlamps with insulated characteristics. Steel and FRP plates are installed on the fixed and movable platens to insulate...

EP - Packaging Injection Molding Machine

Categories : Automatic Injection Molding Machine

● vertical servo motor clamping system. ● Horizontal parting line injection system. ● Sevor motor and air pressure system. ● FUJI 7” full color TFT-LCD touch panel controller. ● 3 stages inje...

Toggle Outward Injection Molding Machine E Series

Categories : Automatic Injection Molding Machine

Plastic (toggle outward) injection molding machines are the particular design of toggle mechanism. They allow the application of the dynamic force concentrated on the centre of the moving platen, e...

Hydraulic Clamping Injection Molding Machine DHT Series

Categories : Automatic Injection Molding Machine

Direct hydraulic clamping injection molding machines are designed without toggle mechanisms that enable to avoid the toggle wear. This model can increase the position accuracy and is good for high ...