2 Shaft Auto Cutter

Categories : Die Cutting Machines

Application:Double side adhesive tape, Paper core, PVC, Rubber, leather, foam… etc. roll tube yicheen

High Precision Die Cutting Machine (Full Electrical, One Sheet Feeding)

Categories : Die Cutting Machines

Application:High precision die cutting machine (Full electrical, one sheet feeding) yicheen

Paper Core cutter

Categories : Die Cutting Machines

Application:Double side adhesive tape, Paper core, PVC, Rubber, leather, foam… etc. roll tube yicheen

High Precision Die Cutting Machine with CCD auto position system

Categories : Die Cutting Machines

Application:Optical film, Plastic film, e.g.: ITO, Diffuser, Reflects film, Brightness Enhancement Film (BEF), Soft PCB, Composite material. The material are not cracked while cutting. yicheen

4 Shaft Auto Cutter

Categories : Die Cutting Machines

Application:To cut the variety of tape rolls, e.g.: double-sided tape, masking tape, Electrical Tape, construction tape, other kinds of tapes. yicheen

HIGH-SPEED STEEL MOLD CUTTER HSP-12

Categories : Die Cutting Machines

Innovative Feed Mechanism: In which, the auto up/down feed system is designed for the height of the molded material. Superb And Stabilized Dead-Point Accuracy: For which the dual-axle synchr...

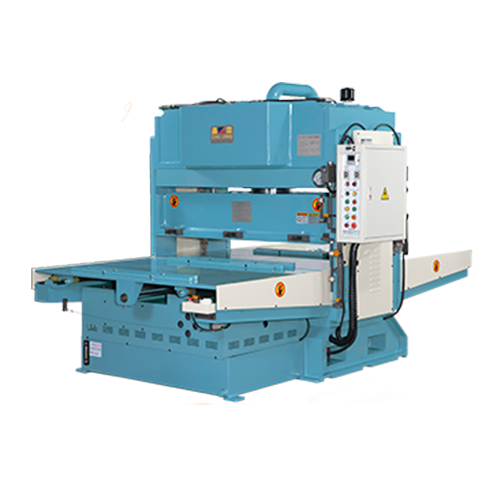

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Die Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of gui...

MULTI-LAYER AUTOMATIC FEED CUTTING MACHINE VAC-310

Categories : Die Cutting Machines

Double-Axle Synchronous Pressurizing Mechanism: Performs the pressurization with double output axle to provide powerful and stabilized pressurizing capacity. Automatic Feed Mechanism: Uses s...

AUTOMATIC FEEDING PRECISION CUTTING MACHINE (ROLL-TO-ROLL) APL-500SP

Categories : Die Cutting Machines

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with liner rail desi...

HIGH ACCURACY AUTOMATIC CUTTER TRC-350

Categories : Die Cutting Machines

Automatic justitying tension control system. This system aim to a design for winding materials, thus making receipt control more steady and smooth. Excellent and stable bottomdead center accuracy...

HIGH-ACCURACY ROLL-TO-ROLL AUTO FEED CUTTING MACHINE TRC-350CP

Categories : Die Cutting Machines

Special Feed Mechanism: Designed for the material having different characteristics to achieve automatic machining for the soft materials. Well-Designed And Stabilized Bottom Dead-Point Accurac...

HIGH PRECISION HYDRAULIC CUTTING PRESS CSS-607

Categories : Die Cutting Machines

The Structure Of Press Body Is Made By Special Steel Shaped Materials That Features Pressure-Resistant Function To Maintain A Permanent Plane, With Its Integrated Shaping Of Punch And Slide To Full...

HIGH ACCURACY AUTOMATIC CUTTER(ROLL TO ROLL) TRC-350GP

Categories : Die Cutting Machines

Automatic justifying tension control system this system aims to a design for winding materials, thus making receipt control more steady and smooth. Excellent and stable bottomdead center accuracy ...

Precision Hydraulic Double-Sided Auto Feed Cutter CSS-806

Categories : Die Cutting Machines

Both double-side and single-side operation, time and manpower saving, one machine for two purposes to give excellent effect of production. Double-side pressure and touch-type electronic counter wa...

HIGH-ACCURACY ROLL-TO-ROLL AUTOMATIC FEED CUTTING MACHINE TRC-350SP

Categories : Die Cutting Machines

Double-Axle Synchronous Feed Mechanism: Enhances the production speed and Yield Rate through double-axle synchronous feeding. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Uses th...