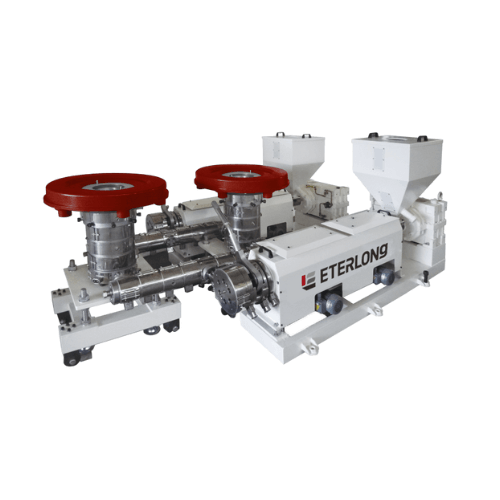

ABA Double Die Blown Film Extruders

Categories : ABA Extrusion Die Head

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. HSIN LONG supply customized machine specifications for different output, material, ...

Two Layer / ABA Die Head

Categories : ABA Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

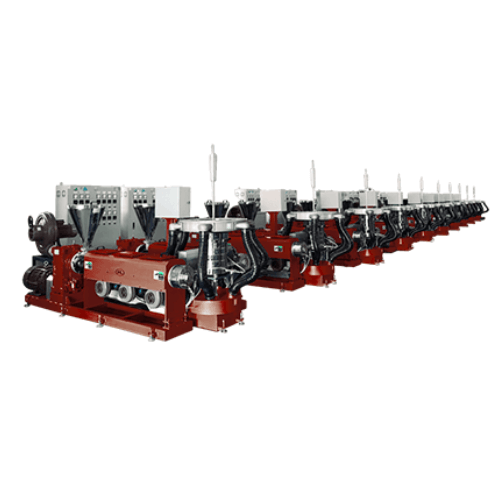

Co-Extrusion Blown Film Extruders

Categories : ABA Extrusion Die Head

HSIN LONG’s Co-Extrusion Extruder is customized which depends on characteristics of raw materials and final applications. Since there are kinds of materials will be extruded at the same time,...

ABA Double Die Head

Categories : ABA Extrusion Die Head

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted po...

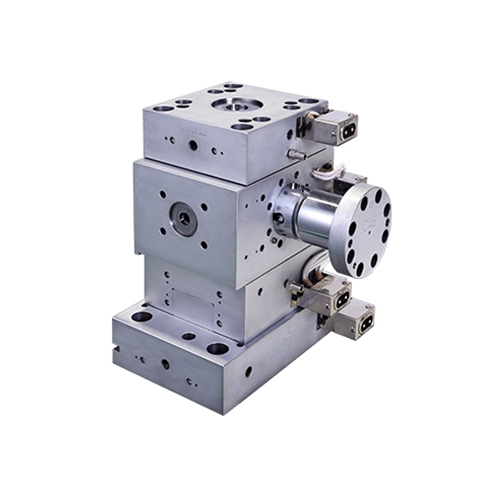

Fix / Variable / Rapid Geometry Feedblock

Categories : ABA Extrusion Die Head

FIX GEOMETRY Simple manifold structure, few retention points Customized manifold design, 2 or 4 inlets, for different Extrusion Die inlet as required by the customer Precision internal manifold des...