Blow Molding Machines by Layers

Layered blow molding machines are designed to produce containers with one or multiple layers of plastic materials, offering advantages in barrier protection, strength, and material optimization. These machines are ideal for packaging applications requiring extended shelf life or enhanced mechanical performance.

PRM-Taiwan offers a wide selection of blow molding solutions categorized by layer configuration, including Mono Layer, Double Layer, and Multi Layer Blow Molding Machines, supporting manufacturers with tailored options for diverse production needs.

Mono Layer Bottom Blow Moulding Machine for 20lt~30lt Jerry Can

Categories : Blow Molding Machines by Layers

Mono Layer Bottom Blow Moulding Machine for 20lt~30lt jerry can Single Head, Single Station

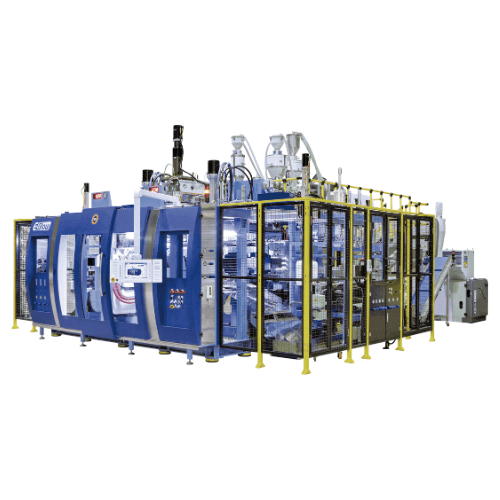

Accumulator Head Blow Moulding Machines-PC Drum

Categories : Blow Molding Machines by Layers

Accumulator Head Blow Molding Machines-PC drum

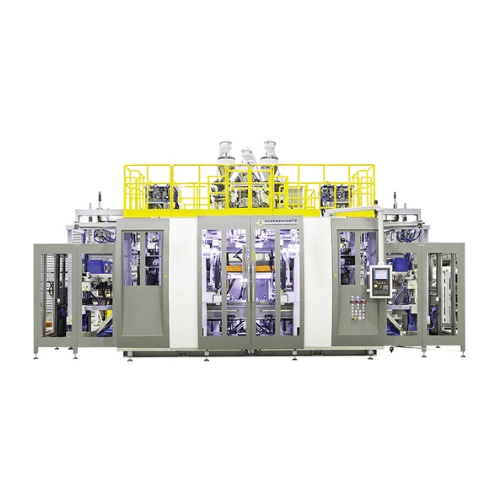

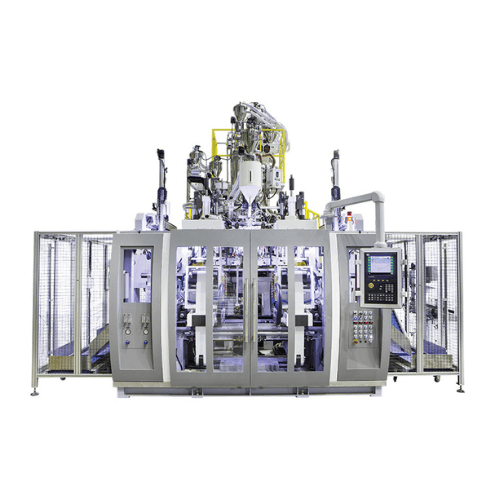

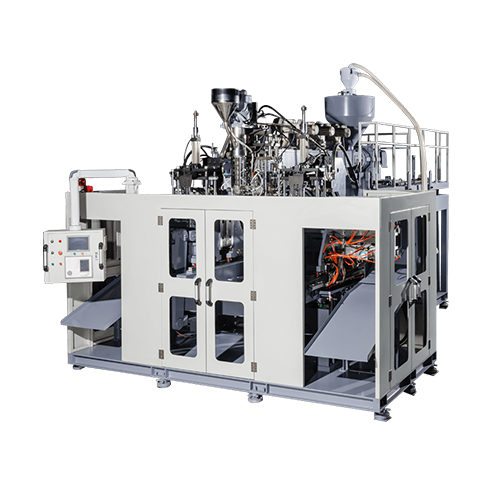

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making

Categories : Blow Molding Machines by Layers

All Electric 3 Layer, Double Station Blow Moulding Machine for Plastic Bottle Making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no po...

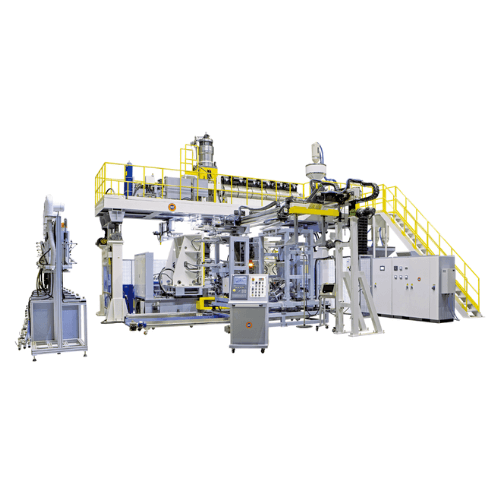

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot, 5 Set Post Cooling Units

Categories : Blow Molding Machines by Layers

3 Layer, Continuous Extrusion Blow Moulding Machine (Fixed Type Clamping Press) 220lt Tight Head Drum

Accumulator Head Blow Moulding Machines-40 Liter Float

Categories : Blow Molding Machines by Layers

Accumulator Head Blow Molding Machines-40 Liter Float

3 Layer Co-Extrustion Bottom Blow Moulding Machine for 20lt~30lt jerry can

Categories : Blow Molding Machines by Layers

3 Layer Co-Extrustion Bottom Blow Moulding Machine for 20lt~30lt jerry can Single Head, Double Station

Blow Molding Machine Multi Layer Series

Categories : Blow Molding Machines by Layers

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottl...

Continuous Co-Extrusion Blow Molding Machine (Multi Layer)

Categories : Blow Molding Machines by Layers

This series is specified for producing particular containers that are fully sealed, light resistant, heat resistant, anti-bacterial, durable, anti-static, corrosion resistant, non-toxic…etc.

HBE Series Mono/Multi-Layer Blow Moulding Machine for 20lt~25lt diamond shape jerry can

Categories : Mono Layer Blow Molding Machines

1.Compact Design & Competitive Price 2.High Putput& Homogenous Mixing Result 3.Fast Colour Change 4.User-Friendly Control System with Remote Control 5.High Production Effc...

2 Layer Co-Extrusion Blow Moulding Machine for 200ml, 400ml Shampoo Bottle

Categories : Blow Molding Machines by Layers

2 Layer Co-Extrusion Blow Moulding Machine for 200ml, 400ml Shampoo Bottle Quad Head, Double Station

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle

Categories : Blow Molding Machines by Layers

4 Layer Co-Extrusion Blow Moulding Machine for 1lt bottle Double Head, Double Station HDPE bottle blow moulding machine

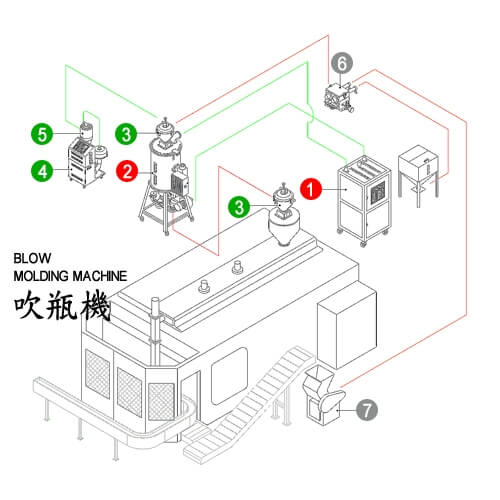

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Blow Molding Machines by Layers

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot

Categories : Blow Molding Machines by Layers

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot

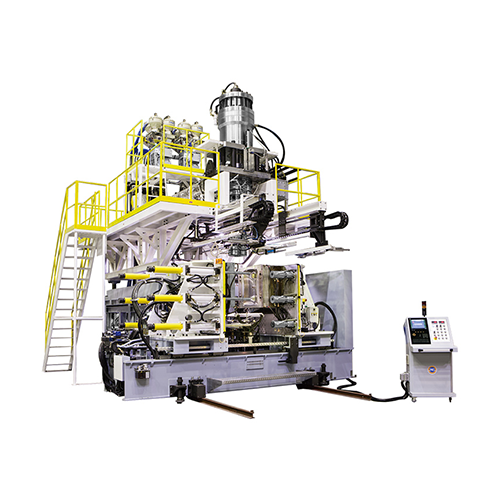

Double Layer Accumulator Head Blow Moulding Machines

Categories : Blow Molding Machines by Layers

Double Layer Accumulator Head Blow Molding Machines

Accumulator Head Blow Moulding Machine for L Ring Drum & Open Top Drum

Categories : Blow Molding Machines by Layers

Accumulator Head Blow Moulding Machine for L Ring Drum & Open Top Drum

Medium Co-extrusion Blow Molding Machine – Double Station

Categories : Blow Molding Machines by Layers

Medium Co Extrusion - Continuous Type Blow Molding Machine Chen Way Machinery is well-known for its 20L three-layer blow molding machines. Three-layer co extrusion blow molding machines are the mo...

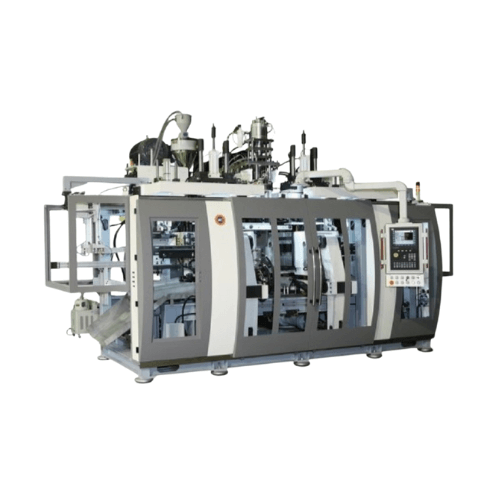

Medium Blow Molding Machine - Double Station

Categories : Blow Molding Machines by Layers

Medium-Continuous Type Blow Molding Machine An all-rounder that is ideal for a variety of applications. Medium blow molding machines are used to produce medium-sized products but can also be adapt...

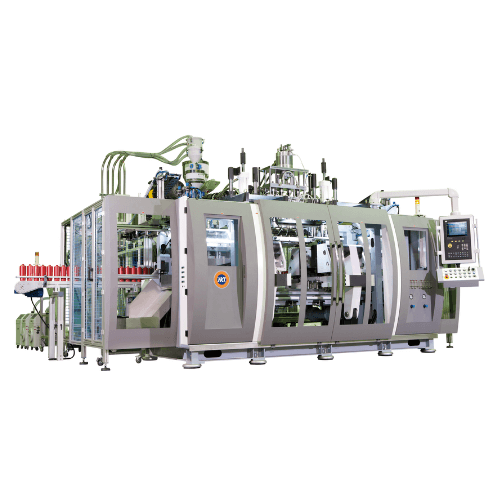

Medium Co-extrusion Blow Molding Machine

Categories : Blow Molding Machines by Layers

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C...

Automatic Blow Molding machine With Pneumatic Clamping System- A Series

Categories : Blow Molding Machines by Layers

This type is the pneumatic-clamping blow-molding machine, suitable for making popsicle (ice-lolly) & various small-size bottles. Extrusion is driven by the inverter motor with pulley-drive gear...

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Blow Molding Machines by Layers

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER C...

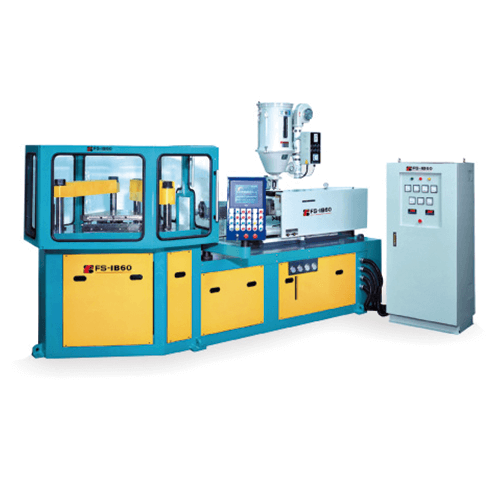

One Step Injection Blow Molding Machine-FS-IB60

Categories : Blow Molding Machines by Layers

Full Shine's Injection Blow Molding Machine is the advanced machine, combining injection molding mechanism with blow molding mechanism together. This machine is suitable for processing PP, PE, ...

Automatic-Blow-Molding-machine-L Series

Categories : Blow Molding Machines by Layers

Full Shine's L Series Blow Molding Machines are suitable for producing big and large containers, such as water tanks, chemical drums, jerry cans, and automobile components. These machines are e...

Semi-Automatic Pet Stretch Blow Molding Machine FS-1000HD2

Categories : Blow Molding Machines by Layers

One Heating Machine One Stretching Machine. Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. Semi-auto PET Stretch Blow Molding Machin...

Automatic-Blow-Molding-Machine-H Series

Categories : Double Layer Blow Molding Machines

Our versatile and efficient plastic blow molding machine can produce a wide variety of products, from 5ml to 10L, with single-station or double-station configurations, monolayer or multi-layer, and...