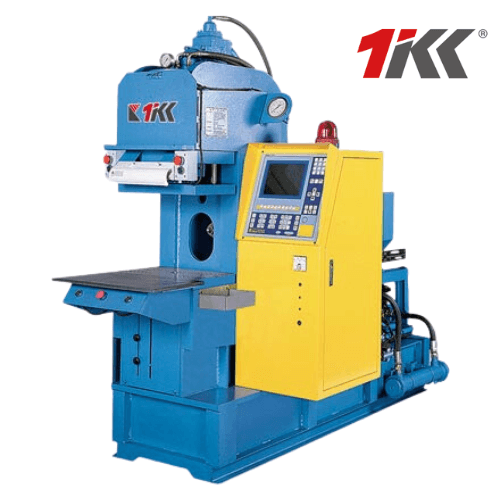

KT Series Injection Molding Machine (ROTARY TABLE)

Categories : Rotary Table Vertical Injection Molding Machines

Vertical mold clamping and injection, small footprint and high degree of precision.....

KC Series Vertical Injection Molding Machine (STANDARD)

Categories : Rotary Table Vertical Injection Molding Machines

Vertical mold clamp and horizontal injection. No-post design is open on three sides and suitable for medium-size injected products with inclusions.....

KC Series Vertical Injection Molding Machine (STANDARD)

Categories : Rotary Table Vertical Injection Molding Machines

Vertical mold clamp and horizontal injection. No-post design is open on three sides and suitable for medium-size injected products with inclusions.....

KC Series Vertical Injection Molding Machine (ROTARY TABLE)

Categories : Rotary Table Vertical Injection Molding Machines

Vertical mold clamp and horizontal injection. No-post design is open on three sides and suitable for medium-size injected products with inclusions.....

KR Series Plastic Injection Molding Machine (ROTARY TABLE)

Categories : Rotary Table Vertical Injection Molding Machines

Maximize productivity with our vertical injection machine. Vertical mold clamp, horizontal injection. Sturdy structure, user-friendly layout. Smooth movement, long lifespan. Customizable func...

YD Vertical Four-Column/Two-Color Rotary Table-Vertical Clamping and Vertical Injection Molding Machines

Categories : Rotary Table Vertical Injection Molding Machines

A. Standard double injection Vertical 4-columns direct-pressure clamping. In the upper mold plate, two separate vertical injection units is installed(separate injection hydraulic oil route) with th...

Four Station Disc Dual Machine Injection - YD SERIES

Categories : Rotary Table Vertical Injection Molding Machines

Four Station Disc Dual Machine Injection - YD SERIES Two independent injection systems with a turntable to allow double injection.

YR Multiple Embedded Rotary Injection Molding Machine Series

Categories : Rotary Table Vertical Injection Molding Machines

Vertical clamping with vertical injection. Rotary table oscillate 180 °, rotate back / forth for easy loading and finished parts pick out, to increase productivity. Rotary table with location p...

Vertical Shuttle Table Injection Molding Machine

Categories : Rotary Table Vertical Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and mo...

Multiple Embedded Rotary Injection Molding Machine-YR Series

Categories : Rotary Table Vertical Injection Molding Machines

• Vertical clamping with vertical injection. • Rotary table oscillate 180 °, rotate back / forth for easy loading and finished parts pick out, to increase productivity. &bu...

Iron Powder Type Machine

Categories : Rotary Table Vertical Injection Molding Machines

Clamping pressure is stable and production efficiency is high.

Vertical Single Shuttle Table Injection Machine

Categories : Rotary Table Vertical Injection Molding Machines

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and mo...

C Type Injection Molding Machine

Categories : Rotary Table Vertical Injection Molding Machines

Tie-bar less (C type) design gives more space for operation. Especially suitable for the power cord and connector with wire. With double slide table or rotary design, put in, takeout products and m...

Vertical Liquid Silicone Rubber Injection Molding Machine

Categories : Rotary Table Vertical Injection Molding Machines

Precision Vertical mold clamping system (Parallelism/ flatness: 0.02/100 mm) with heavy-duty tie-bars works greatly to extend machine & mold life and reduce flash of product.

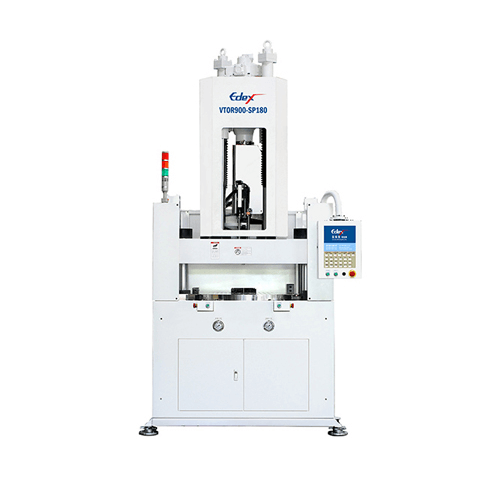

VTOR- Vertical Rotary Injection Molding Machine

Categories : Rotary Table Vertical Injection Molding Machines

● The smallest rotary table design, max mold diameter. ● Suits for Plunger type injection or screw type injection system. ● Patented active bypass auxiliary plasticization system design. ● 2-pla...

C Type / Tie-barless Rotary Table - YC Series

Categories : Rotary Table Vertical Injection Molding Machines

C Type / Tie-barless Rotary Table - YC Series - C-type structure, the deformation is small. Easier for insert molding.