LATEST UPDATE Subscribe Now

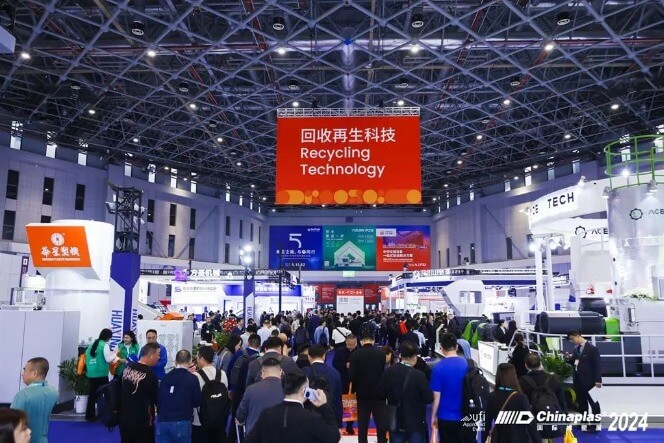

It's Record Breaking! 211,928 Visitors for the First 2 Days!

CHINAPLAS 2024 welcomed a record breaking of 211,928 visitors for the first 2 days. Among them, 44,242 came from overseas, comprising approximately 21% of the total visitors. Day 2 alone witnessed 118,687 visitors, marking a new height for single-day attendance. Of these, 24,862 were overseas visitors (~21%), establishing another new record for the daily overseas visitor no.

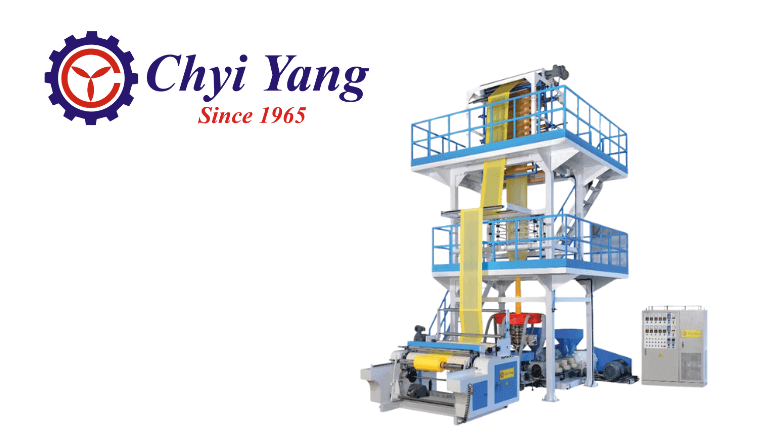

Path to a Greener Tomorrow── Chyi Yang's CFV Solutions of Precision and Sustainability

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

2024 PRM Spotlight Plan: Monthly Success Stories of Taiwanese Suppliers

In this article, we delve into the "Spotlight" plan, a monthly showcase that highlights the exemplary efforts of Taiwanese suppliers in tailoring solutions to meet customer needs, fostering innovation, and driving the industry forward. Though the export data for Taiwan machinery decreases in 2023 due to the economic recession, the excellent suppliers must be seen. And that's why PRM, as a pioneer media in the Plastic and Rubber industry, devoted itself to promoting Taiwanese brands.

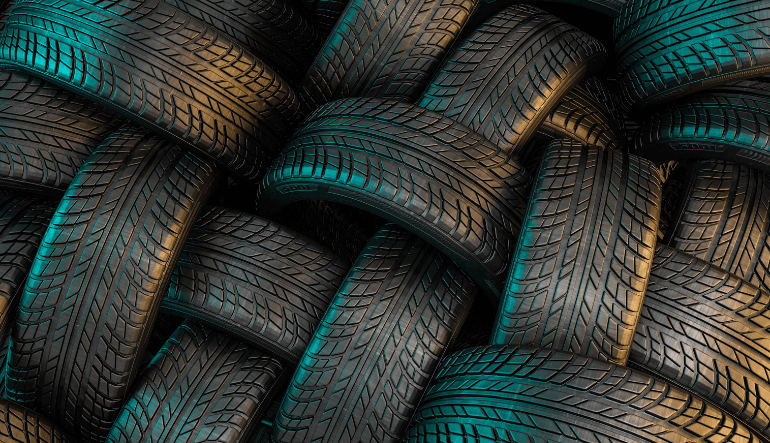

Advanced Technologies Could Process 20 Percent of U.K.’s Waste Tires

Norwegian rubber waste recycler Wastefront is set to open a $120 million plant in Sunderland, England, either late in 2024 or early 2025. The plant will utilize pyrolysis to convert end-of-life tires into tire-derived oil (TDO), which will then be refined into various combustion fuels, including diesel. Wastefront claims that the TDO produced will be cleaner than fossil diesel and cost-competitive, depending on the grade. It is expected to be cheaper than hydrotreated vegetable oil and similar biofuels.

CHYI YANG: Transforming Waste into Gold, ABA Co-extrusion Machine Revolutionized Bag Manufacturing

The unique die head design of the ABA co-extrusion machines offers producers cost management flexibility by incorporating an middle layer of recycled material or calcium carbonate compound, effectively reducing raw material expenses. This not only maintains competitiveness in raw material prices but also aligns with environmental trends.

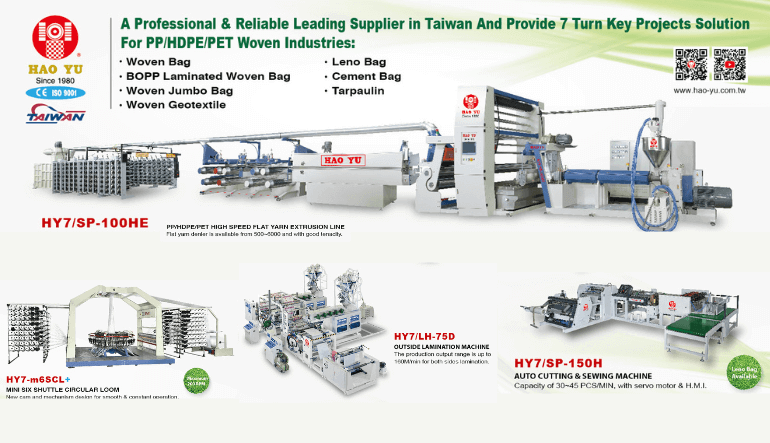

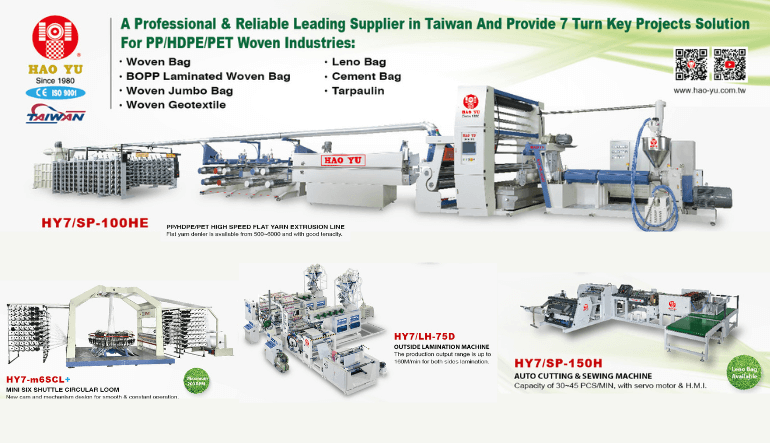

HAO YU: Pioneering Excellence in Woven Bag Machinery Since 1980

HAO YU Precision Machinery Industry Co., Ltd. is a one of the skillful & experienced manufacturers of PP and HDPE woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence.

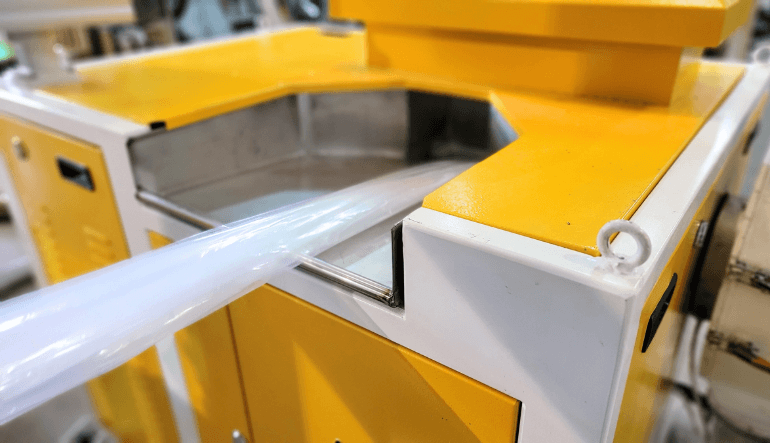

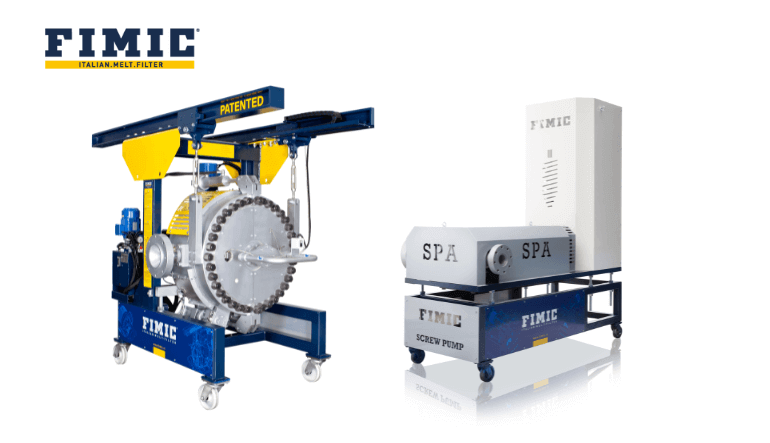

FIMIC Innovations in Automatic Filtration

Recycling is a game where size matters. Nowadays recyclers need to reach a higher hourly production capacity with efficiency and simplicity, they required right applications for high-throughput recycling lines. FIMIC has been working many years now on improving its filtration technologies in order to meet and satisfy the needs (quality, characteristics) of recyclers, and at the same time facing the challenges of recycling post-consumer and post-industrial plastics.

ETERLONG: Your All-In-One Solution for Blown Film Machines

ETERLONG – A merger with the leading Blown Film Die manufacturer former brand HSIN LONG. Continuation of HL spirit and experiences, in addition, ETERLONG have advanced production facilities and acquire IoT (Internet of Things) intelligent equipment to expand production capacity. We are dedicated to create All-in-One to deliver great service to make customers simple choices, they can purchase not only individual components but also complete Blown Film Machines, all from ETERLONG.

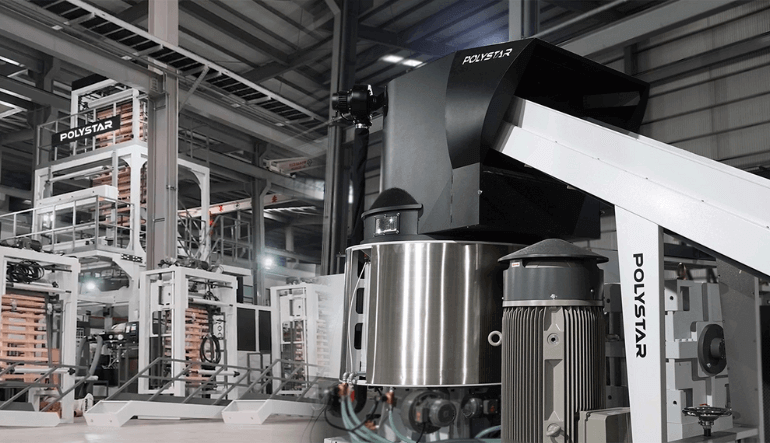

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

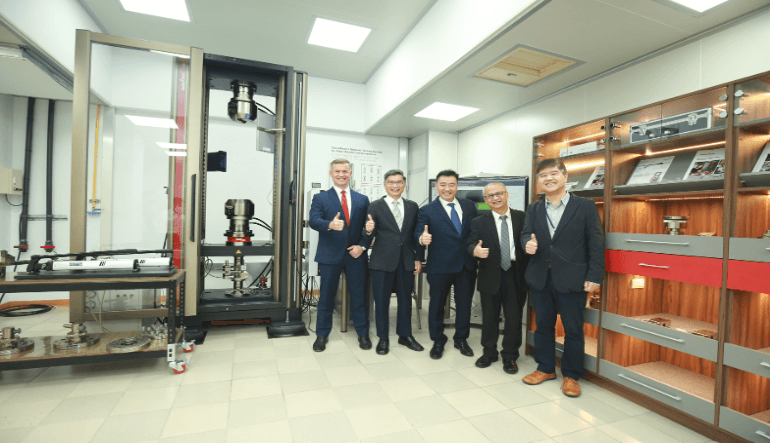

台德合作!塑膠中心促亞太區複材實驗室成立

【新唐人亞太台 2022 年 11 月 24 日訊】 第3屆塑膠產業創新論壇週三(23日)登場,今年以塑膠產業永續發展為題,推出2場論壇及技術研討會系列活動,展出超過100項的焦點技術,吸引塑化業者超過300位出席。 由塑膠中心邱政文副總經理於擔任座談交流會主持人,分享複材產品研發國內已具備技術實力,有賴各界合作,共朝創新高值產品如航太、國防等高階領域開創。天力技術處長王柏棋、塑膠中心博士張修誠,以及虎科大飛機工程系助理教授王正賢,也分享產業技術發展和關鍵人才養成。

Introduction to ETERPLAST™

ETERNAL ETERPLAST™ thermoplastic composite materials have the characteristics of high strength, high impact resistance, low moisture absorption, high dimensional stability, and repeatable molding. Different temperature-resistant materials can also be provided according to customer needs.

HAO YU: Pioneering Excellence in Woven Bag Machinery Since 1980

HAO YU Precision Machinery Industry Co., Ltd. is a one of the skillful & experienced manufacturers of PP and HDPE woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence.