Hot plate heating type forming tools

Categories : Blow Molding Molds

Hot plate heating type forming molds is mainly for producing OPS products like containers, trays, and lids......etc. The post-treatment process is required for continuous trimming.

PET Blow Mold / PET Preform Mold

Categories : Preform Molds

PET Blow Mold / PET Preform Mold ● Molds are designed for high performance using alloy steels and stainless steels, which guarantee maximum precision, high stability, and long life.

Quick Change Die System

Categories : Blow Molding Molds

It is an era for making high frequency of die changing with multiple patterns and small quantity. In order to save die changing time and ensure operational safety, it is just in time to apply Quick...

Stretch Blow Molding Machine Main Part

Categories : Stretch Blow Molding Molds

STRETCH BLOW MOLDING MOLD

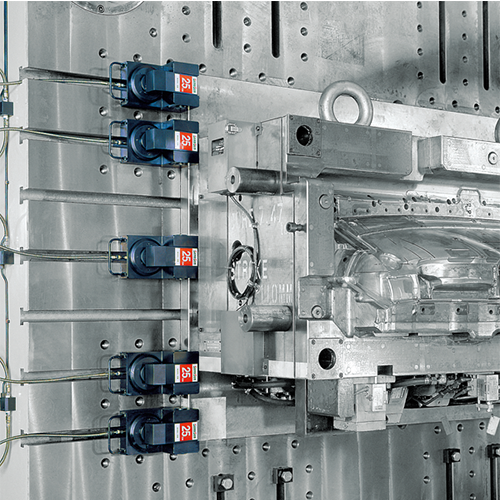

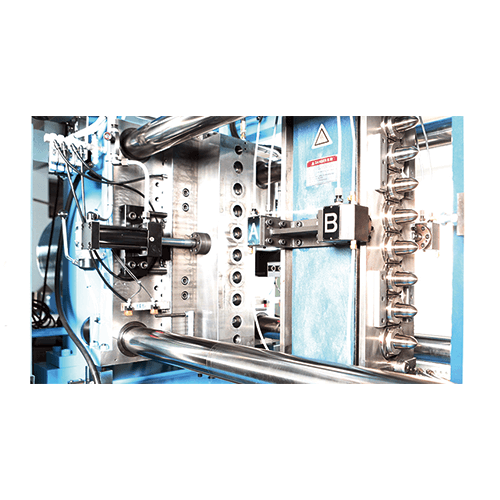

Quick Mold Change System

Categories : Blow Molding Molds

It is an era for making high frequency mold change with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to...

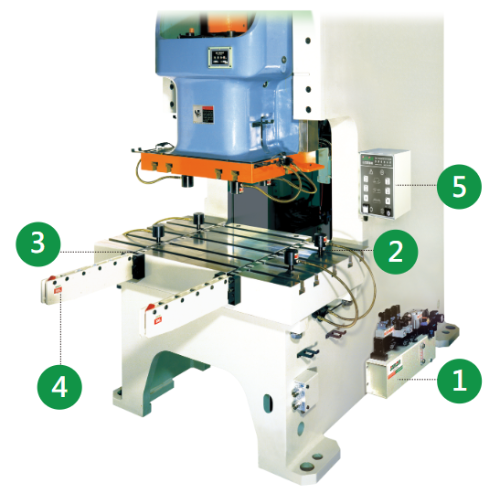

Mold Flip Device For Press

Categories : Blow Molding Molds

Mold Flip device using electric hydraulic motor, move up-down and flip mold through hydraulic power. Using the Mold Flip device can raise work efficiency and also reach zero accident happens. If po...

Mold Changer System

Categories : Blow Molding Molds

FEATURES Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival and positioning in the process of mold mov-in...

GF/IB-Series Mould

Categories : Preform Molds

●Common mold base design makes the best use of the resources. 1, 2 ,3-cavity or 1, 2, 5-cavity can share the same mold base. ●Interchangeable insert mold design simplifies the mold changeover and r...

Series Mould GF/ISB

Categories : Preform Molds

The machine equips the unique device of Vertical Rotary Disc to transfer the preform from one station to another in an upright position. (Patent)