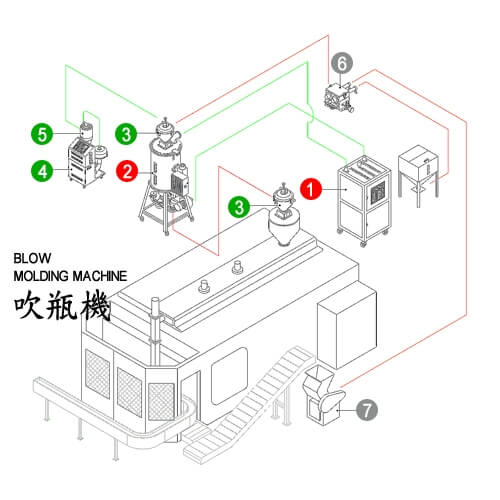

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Co Extrusion Blow Molding Machine

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

Continuous Co-Extrusion Blow Molding Machine (Multi Layer)

Categories : Co Extrusion Blow Molding Machine

This series is specified for producing particular containers that are fully sealed, light resistant, heat resistant, anti-bacterial, durable, anti-static, corrosion resistant, non-toxic…etc.

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Co Extrusion Blow Molding Machine

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is ...

Automatic-Blow-Molding-Machine-H Series

Categories : Co Extrusion Blow Molding Machine

Our versatile and efficient plastic blow molding machine can produce a wide variety of products, from 5ml to 10L, with single-station or double-station configurations, monolayer or multi-layer, and...

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Co Extrusion Blow Molding Machine

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER C...

Medium Co-extrusion Blow Molding Machine

Categories : Co Extrusion Blow Molding Machine

Chen Way machinery is well-known for its 20L three layers blow molding machine. The recycle resins and the calcium carbonate (CaCO3) in the middle layer help to save material cost. Three layers M/C...

Medium Co-extrusion Blow Molding Machine – Double Station

Categories : Co Extrusion Blow Molding Machine

Medium Co Extrusion - Continuous Type Blow Molding Machine Chen Way Machinery is well-known for its 20L three-layer blow molding machines. Three-layer co extrusion blow molding machines are the mo...