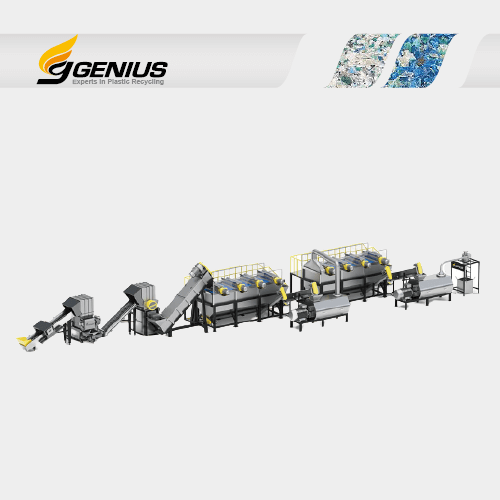

Micro Denier Filament Grade PET Bottle Washing Line

Categories : Bottle Washing Line

Micro Denier Filament Grade PET Bottle Washing Line

RDF-5, Twin Screw Rubbing Drying Machine

Categories : Squeezers

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer fo...

Crushing, Washing And Drying Whole Plant Facility For Plastic Scrap

Categories : Bottle Washing Line

Suitable for washed plastic scraps Good at water removal. The residual moisture after drying could be around 1-3%. Whole set of electric facility are with automatic startup to protect w...

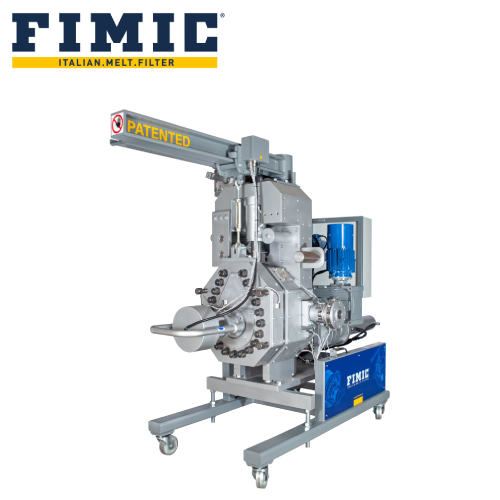

Automatic Melt Filter - RAS+REF

Categories : Squeezers

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in sc...

Horizontal Centrifugal Dryer

Categories : Film Washing Lines

Suitable for washed plastic scraps Good at water removal. The residual moisture after drying could be around 1-3%. Maximum capacity could reach 1 ton/hr for plastic scraps drying. With st...

Success Story - Plastic Squeeze Dryer

Categories : Squeezers

DW-350 / Plastic Squeeze Dryer / Washed PE Film / South Africa DW-300 / Plastic Squeeze Dryer / LDPE Film / Romania DW-350 / Plastic Squeeze Dryer / Washed PP Woven Bag / Spain Japan Subsidy Policy...

Rigid Plastics and PE Film Recycling System

Categories : Bottle Washing Line

Rigid Plastics and PE Film Recycling System

PET Bottle Recycling Washing System

Categories : Bottle Washing Line

PET bottles bales to PET flakes

AUTOMATIC MELT FILTER- TEN

Categories : Squeezers

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the req...

Single Screw Rubbing Drying Machine

Categories : Squeezers

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer fo...

Success Story - Force Side Feeding Plastic Recycling Machine

Categories : Plastic Washing Line

RECO-Z-125i / Force Side Feeding Plastic Recycling Machine / Washed PE Film / Taiwan RECO-Y-150i / Force Side Feeding Plastic Recycling Machine / HDPE bottle / Taiwan

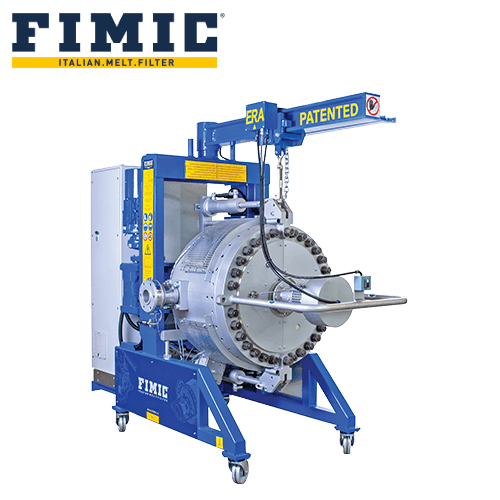

Automatic DOUBLE FILTER- ERA

Categories : Rigid Plastic Washing Line

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machin...

Twin Screw Squeezing Machine (RDF-5)

Categories : Squeezers

With a special designed twin screw, it is capable to squeeze and form multiple types of material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put i...

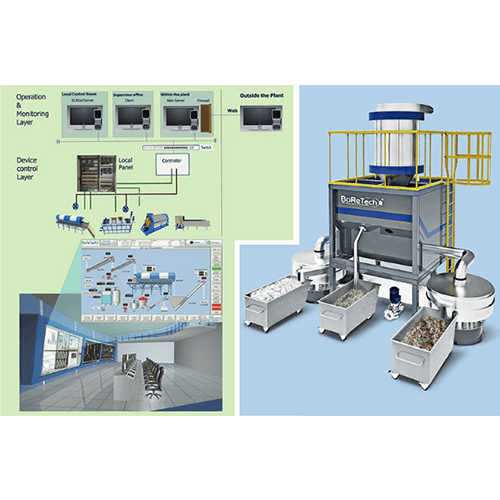

Self-Clean Hydro Dryer

Categories : Flake Washing Machines

Boretech's Self-Clean Hydro Dryer is a centrifugal dewatering equipment with automatic cleaning function. Under the processing capacity of 3t/h, the water content of the material in the dehydra...

Turbo Washer - PET Flakes Friction Washer

Categories : Bottle Washing Line

Turbo Washer - PET Flakes Friction Washer

PET Bottle Recycling Washing System

Categories : Bottle Washing Line

PET Bottle Recycling Washing System

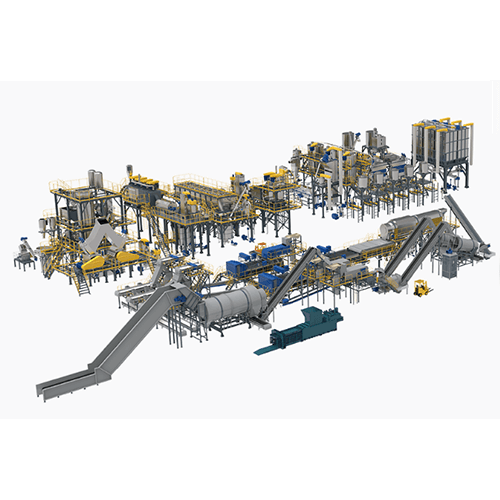

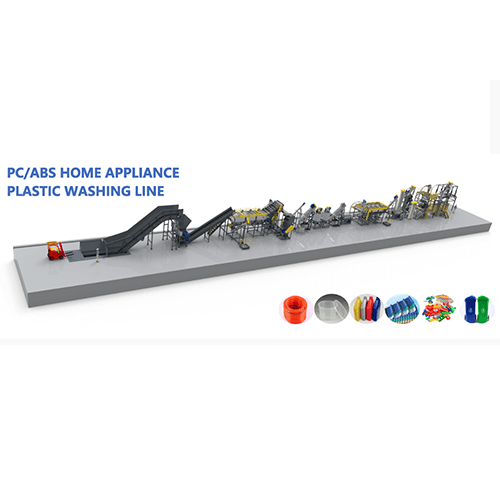

Rigid Washing Line

Categories : Rigid Plastic Washing Line

The rigid washing plants are designed for recycling post-consumer hard materials like bottles, injection waste, or rigid materials. These systems produce uniform plastic flakes with high purity and...

Rigid Plastics Recycling System

Categories : Rigid Plastic Washing Line

Rigid Plastics Recycling System

Single Screw Squeezing Drying Machine

Categories : Film Washing Lines

With a special designed screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granul...

Plastic Recycling Machinery and Equipment

Categories : Plastic Washing Line

The equipment is specially designed for reproducing wastage from PP/HDPE woven bags. BOPP, film.

Plastic Squeeze Dryer (DW Series)

Categories : Squeezers

Lower moisture, higher capacity A plastic squeeze dryer is a vital part of the plastic film washing line. Washed films retain up to 30% wetness normally. High humidity will be affecting the efficie...

Success Story - Waste Plastic Wash Plant

Categories : Plastic Washing Line

Waste Plastic Film Wash Plant / PE Film / Taiwan