Injection Molding Machines by Color

Injection molding machines by color are categorized based on the number of colors used in production—single-color, two-color, or multi-color machines. By using multiple injection units and rotary mold systems, manufacturers can produce parts with different colors or materials. These machines are commonly used in 3C electronics, automotive interiors, stationery, household appliance knobs, and consumer goods.

PRM-Taiwan offers complete color-based injection molding solutions, including Single Color, Two Color, and Multi Color Injection Molding Machines, helping companies achieve product diversity and process integration.

Rotary Table / Separated Injection Multi-color Plastic Injection Molding Machines. Co-injection Multi-color Plastic Injection Molding Machines - TWR/TXIIR SERIES

Categories : Injection Molding Machines by Color

Increase The Flexibility Of Product Design : Molding process can minimize the use of internal space simultaneously. In addition, it can have different applications to increase the flexibility an...

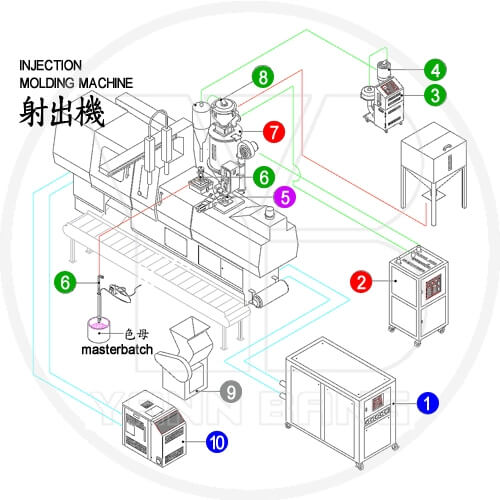

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Injection Molding Machines by Color

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperat...

Outward Toggle Type Plastic Injection Molding Machine - TWII-Series

Categories : Injection Molding Machines by Color

Outward Toggle Clamping a Significant Increase in Structural Accuracy of Mold Platen Benefit: High Rigidity / Highly Precise Injection, Energy Saving / Customization Plasticized Applications: Prefo...

Sandwich / Interval Injection Molding Machine (FB-C Series)

Categories : Injection Molding Machines by Color

It is sandwich/interval injection molding equipment, which is suitable for producing two-component sandwich, interval, pattern and other products.

PET Preform Series Injection Molding Machine - PET Series

Categories : Injection Molding Machines by Color

CHUAN LIH FA offers a full series of plastic injection molding machines for big, medium and small mouth PET preform production...

Double injection molding machine – HDC series

Categories : Two Color Injection Molding Machine

The standard HDC series has two parallel horizontal injection unit to be able to produce a 2-color and 2 plastic material in a time to save time and increase the productivity. To equip Huarong&rsqu...

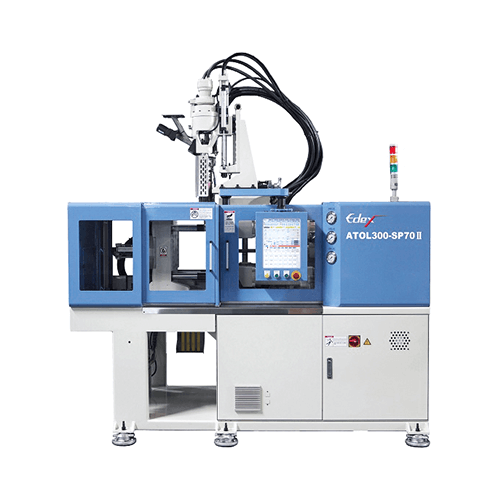

ATOL- Horizontal Multi-color/resin Injection Molding Machine

Categories : Two Color Injection Molding Machine

● Single, dual, triple color/resin in one machine. ● Suits for Plunger type injection or screw type injection system. ● 2-platen 4-cylinder direct clamping system. ● Patented central-radial plat...

Dual / Two Color Injection Molding Machine DNT Series

Categories : Two Color Injection Molding Machine

Dual color injection molding machines are dual color demand with two injection units that enable to perform two color at one time and spare second processing time.

Multi-Color Injection Molding Machine

Categories : Injection Molding Machines by Color

Tie-bar less and big rotary design gives more space for operation. The cable hanger set up in the center of the rotary and out of the molding area, avoids any danger when workers insert the cables ...

Dual Color Injection Molding Machine (DCV Series)

Categories : Injection Molding Machines by Color

• Effectively eliminating rotary inertia, adopting mechanical design for orientation and orienting turntable table by to-and-fro rotary. • With alternative rotary methods, machi...

Mixing Color Injection Molding Machine 120BS to 300BS

Categories : Injection Molding Machines by Color

Several embedded injection processes on two barrels to inject two melts on different stages. Times or positions to create different layouts are found in molding parts.