Energy-Efficient Hopper Dryer(G series)

Categories : Hopper Dryers

Awarded patents in Germany, Taiwan and China, the advanced technology recycles internal heat and faster heating. That saves your energy over 30% and extend equipment life time. Work with a dehumidi...

Hopper Dryers - SHD-U

Categories : Hopper Dryers

SHD-U hopper dryer can efficiently dry most of standard hygroscopic plastics as to ensure high quality molding products. The concise structure makes it easy to mount on the IMM, and the drying hopp...

Crystallized Hopper Dryer(CHD)

Categories : Hopper Dryers

The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper. The unique mixer stirs the resin simultaneously while the unit is drying. To crystallize, it inc...

Dual-chamber Dehumidifying Dryer

Categories : Hopper Dryers

With patented dual-chamber design, the unit can dehumidifying better and save more power energy for you. The model suits to the hopper dryer for large size per hour capacity.

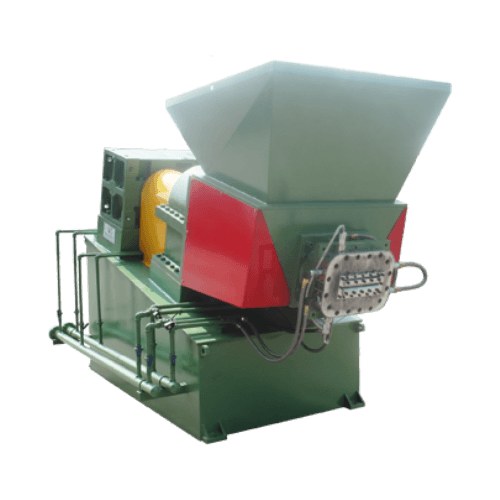

Taper Screw Batch Pre-former

Categories : Hopper Dryers

FUNCTION: This uniquely designed Taper Twin Screw Extruder has a large volume open top hopper, which will accept a whole batch from your mixer without performing. The twin screws continuously and a...

Cabinet Dryers - CD

Categories : Hopper Dryers

CD series of cabinet dryers are mostly used for simultaneous drying of different kinds of polymers in small quantities or for drying materials for trial molding. They can also be applied in electro...

Patented Housing Desiccant Rotor Dehumidifying Dryer (DHML)

Categories : Hopper Dryers

Patented Housing Desiccant Rotor Dehumidifying Dryer (DHML) 1. Unique design of insulated desiccant rotor system. 2. Efficient and energy saving design of exclusive rotation mechanism for the rotor...

Energy-efficient Hopper Dryer-SEHD

Categories : Hopper Dryers

The SEHD energy-efficient hopper dryer can be used for drying most non-hygroscopic materials, such as PS, PP, ABS, etc. The maximum drying temperature can reach 160℃ and it also can choose the opti...

Micro Dehumidifying Dryer (DHM-SL )

Categories : Hopper Dryers

The latest micro dehumidifying dryer uses compressed air to dry the plastic resin. The air volume generated by the air compressor is suitable for the production of small parts, such as electronics ...

Mould Dryer / Mold Dryer (AC)

Categories : Hopper Dryers

Too high humidity in air may affect the quality of your mold surface because of the condensation forming on the molded surface. An industrial air conditioner is perfect working with preform injecti...

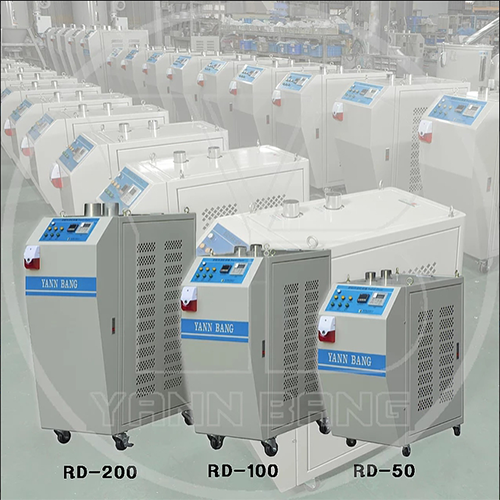

Rapid Dryer (RD)

Categories : Hopper Dryers

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently. 1. Wide application. Suit to numerous material such as PC,...

Oven Dryer (YBO)

Categories : Hopper Dryers

The Oven Dryer is a compact, convenient drying equipment which can dry more than one type of resin at the same. For plastics use, it can be used for annealing and product testing after molding. It ...

“All-in-One” Compact Dryers - SCD

Categories : Hopper Dryers

Shini "optical" compact dryers combine the function of dehumidifying, drying and two-stage conveying into one single unit, specified for the production of "optical class" produc...

Stainless Hopper Dryer for Optics (HD-S / DHD-S)

Categories : Hopper Dryers

The perfect dry capacity is special for optics and electronics use. Unique design is dust-free and clean-free. Stainless and polish one-unit hopper is compact and light weight to install on th...

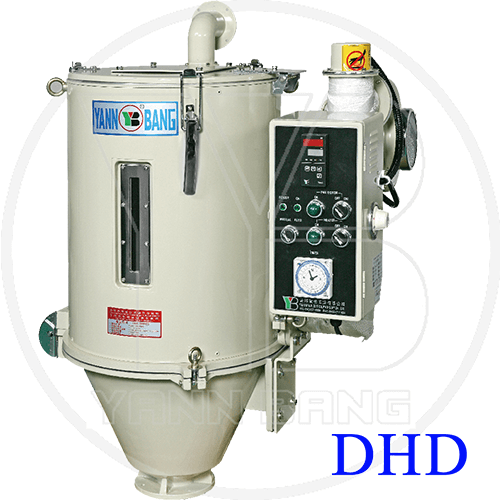

Hopper Dryer (HD/IHD/DHD)

Categories : Hopper Dryers

‧ HD Series Rapid heating. Constant temperature control. ‧ IHD Series Special insulated design. Energy saving. Save against burns. ‧ DHD Series Insulated design. Dust-free, clean free. The standard...

2-in-1 Conveying Dryer (CD)

Categories : Hopper Dryers

Hopper dryer combine vacuum loader is perfect to move anywhere for your need. A stainless insulated hopper dryer with dual layer to help drying better and faster. Save more energy and increase high...

Multi-function Dehumidifying Dryer (DHC-NA)

Categories : Hopper Dryers

Multi-function Dehumidifying Dryer (DHC-NA) Three-in-one design can dry, dehumidify, and automatically convey resins, save money. 1. Low n...

Vertical Type Continuous Dryer

Categories : Hopper Dryers

High efficiency dryer continues feeding wet materials and continues discharging materials improving traditional dryer to dry wet materials by lot saving your time and cost.