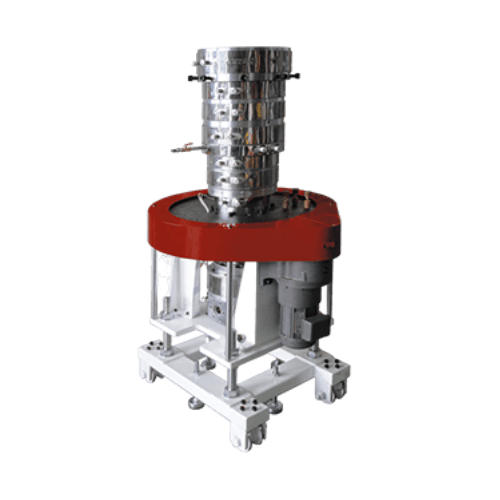

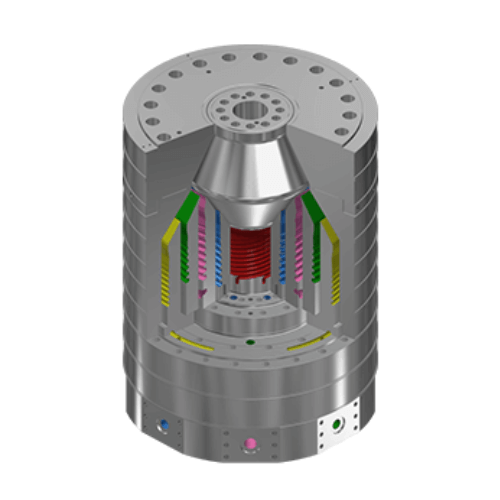

5 Layer Die Head

Categories : Multi Layer Extrusion Die Head

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted po...

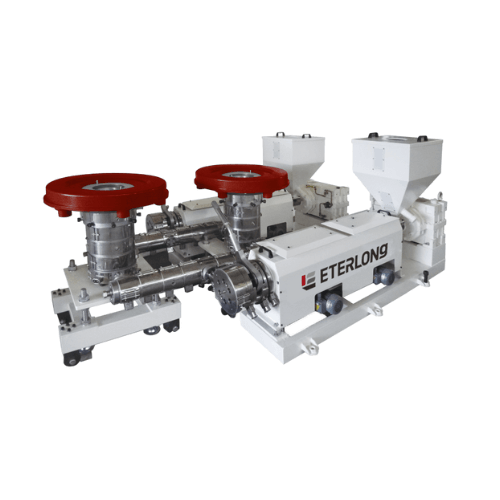

ABA Double Die Blown Film Extruders

Categories : ABA Extrusion Die Head

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. HSIN LONG supply customized machine specifications for different output, material, ...

Hot plate heating type forming tools

Categories : Extrusion Dies / Dies Heads

Hot plate heating type forming molds is mainly for producing OPS products like containers, trays, and lids......etc. The post-treatment process is required for continuous trimming.

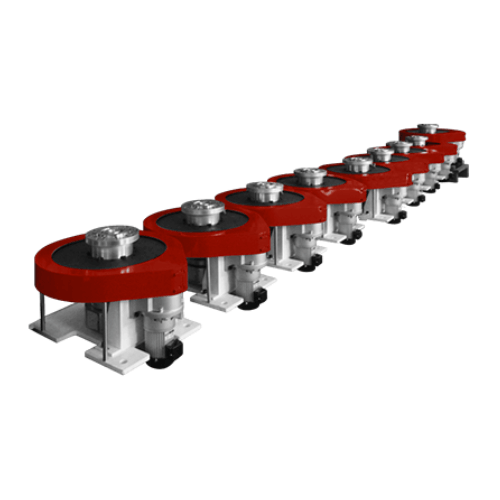

7 Layer Die Head

Categories : Multi Layer Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

Rotary Die Head by CE Making

Categories : Rotating Dies

•Single, two-layer configuration to choose from. •Designed for greatly upgrading thickness uniformity of film. •Optional: Electronic control, frequency converter, etc. HSIN LONG

Extruder Screws and Barrels

Categories : Twin Screw Extruder Die

We develop and produce single screws and twin-screw, their diameter ranges up to 132 mm and length to 3,700 mm. We only use a material that is imported from Germany or Japan once the geometry has b...

Single Layer Die Head

Categories : Multi Layer Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

Two Color And Multi-Color Die Head

Categories : Multi Layer Extrusion Die Head

•Die head can be manufactured to meet customer’s specific extruding capacity and bag width. •Precision construction throughout assures maximum uniformity of film thickness. •Di...

Co-Extrusion Blown Film Extruders

Categories : ABA Extrusion Die Head

HSIN LONG’s Co-Extrusion Extruder is customized which depends on characteristics of raw materials and final applications. Since there are kinds of materials will be extruded at the same time,...

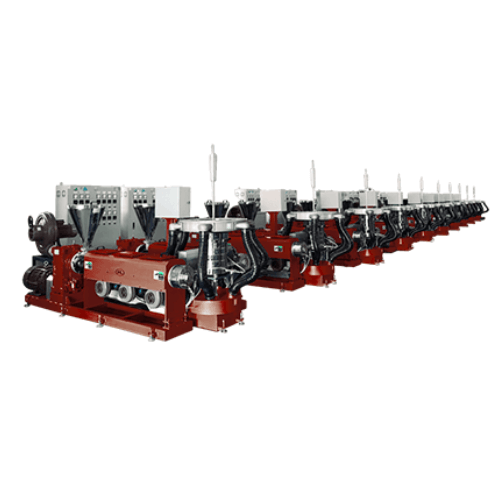

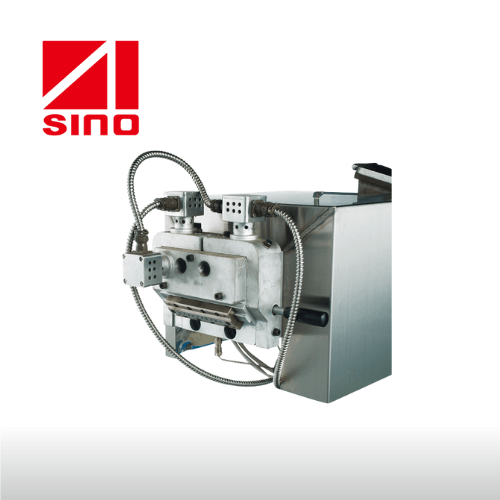

Strand Die-PSZ

Categories : Extrusion Dies / Dies Heads

The PSZ series strand die was developed by Sino-Alloy Machinery as an important accessory to their extruder line and essential for strand pelletizing. In order to improve the flow smoothness, ...

ABA Double Die Head

Categories : Multi Layer Extrusion Die Head

The Blown Film Die Head is the core component which is called the ‘‘heart’’ of the Plastic Film Blowing Machine. The main function of Die Head is to distribute the melted po...

Two Layer / ABA Die Head

Categories : Multi Layer Extrusion Die Head

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered...

Stacked & Multilayer Type Die Heads

Categories : Multi Layer Extrusion Die Head

+For all kinds of blown film machines and it is suitable for multi-layer products. +The stacked design provides high stability & good quality.

Single Layer Die Head for HDPE or LDPE or PP

Categories : Multi Layer Extrusion Die Head

+Suitable for HDPE, LDPE & LLDPE Blown Film Machine. +Low pressure and spiral design provide high stability & high production. +All steel is made of Japanese SCM-440 through strict &...

Rotary Die Head & Rotator

Categories : Rotating Dies

+For LDPE / LLDPE blown film machine. +To stablely control the product thickness, enhance cooling effect and improve product quality.

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

Categories : Multi Layer Extrusion Die Head

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

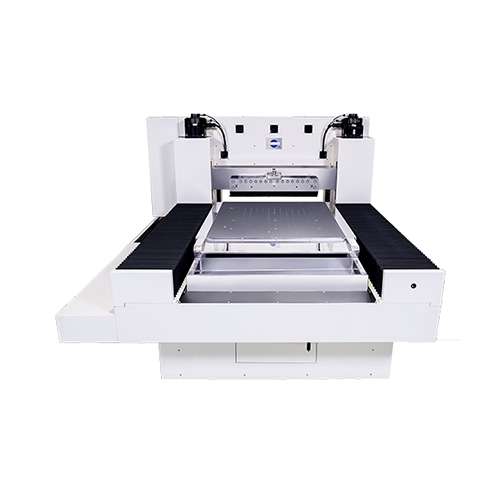

Coating Equipment Sheet To Sheet Coater

Categories : Coating Dies

Slit Die coating on sheet substrate to check the coating thickness and uniformity. SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid

Coating Dies Slot / Slit

Categories : Coating Dies

Slot/Slit design, excellent manifold geometry design, solvent resistant alloy, super mirror grinding technique SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid Straightness precisio...

Hollow Plate Extrusion Dieing Machines

Categories : Hollow Sheet Extrusion Dies

PP/PC HOLLOW PLATE EXTRUSION DIEING MACHINES

Extrusion Dies Lamination

Categories : Coating Dies

EXTRUSION DIES LAMINATING DIES CFJ Width: 500 ~ 5000 mm Die lip span: 0.6 ~ 1 mm Extrusion capacity: 100 ~ 500 kg/hr Width adjustment: internal deckle system Die lip adjustment: manual or motor dri...