Screen Changers / Filters

Screen changers and filters are critical components in extrusion and recycling processes. They remove impurities and ensure material purity by filtering out contaminants during melt processing. These systems help maintain stable pressure, improve product quality, and extend the lifespan of downstream equipment.

PRM-Taiwan provides a range of screen changers and filter systems from Taiwanese manufacturers, including automatic, continuous, and manual models. Whether you're processing virgin resin or recycled plastic, our screen changers and filters ensure consistent filtration performance and operational efficiency.

Options: Double Plates For Extrusion Machine

Categories : Screen Changers / Filters

Non-stop screen-changer system to keep the production operate while replacing the filter plate. With 2 honeycombed plate to increase the leached area and efficiency.

Extrusion Filter

Categories : Screen Changers / Filters

Extrusion Filter is the most economical way to be installed in Plastic Film Blowing Machine. The characteristic of Extrusion Filter can save time and simplize operation step or process. The Extrusi...

Dual-Piston Filter

Categories : Screen Changers / Filters

Bigger Filtration Area, Less Frequent Mesh Change Compared to the slide type product, the dual-piston filters have a larger filtration area which reduces the frequency of changing the mesh and the ...

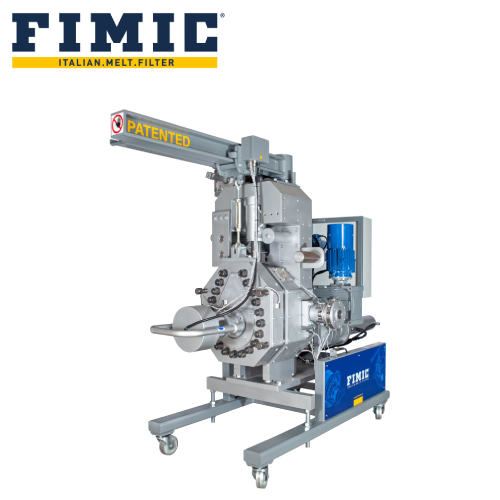

AUTOMATIC MELT FILTER- TEN

Categories : Screen Changers / Filters

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the req...

EXCLUSIVE MELT FILTER- GEM

Categories : Screen Changers / Filters

Differently from RAS, this model reaches a greater filtering surface due to the presence of two filtering meshes towards which all the melt is directed, alongside two scrapers and independent disch...

Automatic self-cleaning screen changer - RAS

Categories : Screen Changers / Filters

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve....

Filtering System: Back Flush For Extrusion Machine

Categories : Screen Changers / Filters

Non-stop screen-changer system to keep the production operate while replacing the filter plate. With 4 removable-honeycombed plate to increase the leached area and efficiency. Decrease the co...

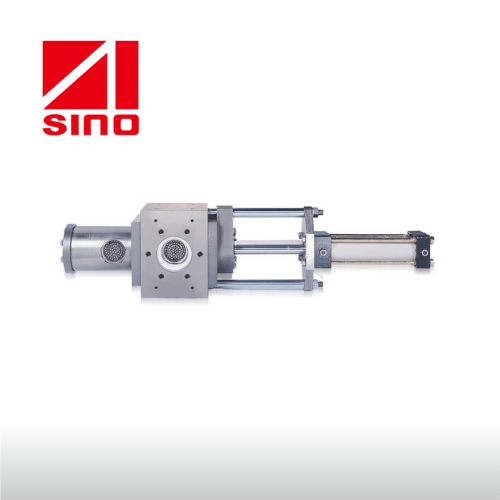

Screen Changer-PSG

Categories : Screen Changers / Filters

The PSG series hydraulic screen changer was developed by Sino-Alloy Machinery as an important accessory for filtering out contaminants. Suitable for filtering out impurities and the amount of ...

Plate Filter

Categories : Screen Changers / Filters

Cost Reduction The mesh can be re-used after cleaning up. Automatic Screen Monitor System The automatic pressure monitor system is capable of non-stop operation with the pressure sensor from &ldquo...

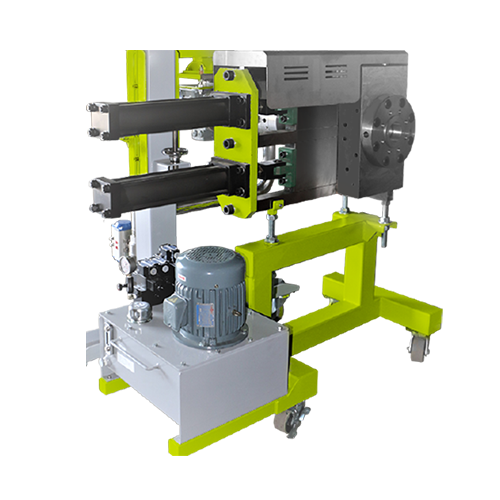

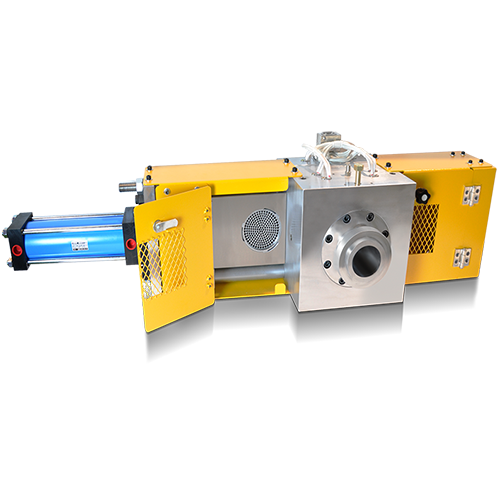

Filtering System: Double Pistons For Extrusion Machine

Categories : Screen Changers / Filters

Double Pistons For Extrusion Machine Non-stop screen-changer system to keep the production operate while replacing the filter plate. With 4 removable-honeycombed plate to increase the leached ar...

RAS UP 800

Categories : Screen Changers / Filters

FIMIC’s latest innovations are aimed to address the current challenges in the plastics recycling industry. RAS 800 is the new addition to the automatic self-cleaning melt filters models produ...

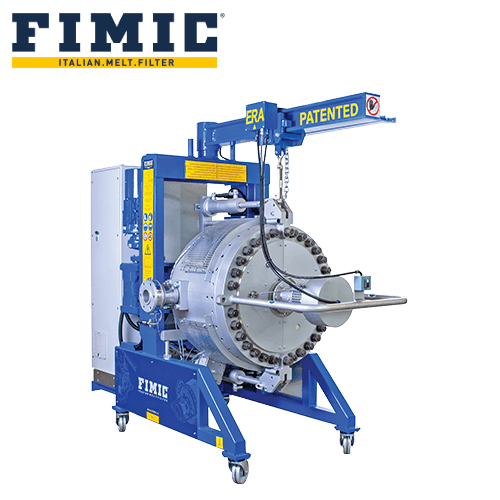

Automatic DOUBLE FILTER- ERA

Categories : Screen Changers / Filters

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machin...

Automatic Melt Filter - RAS+REF

Categories : Screen Changers / Filters

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in sc...

Self-Cleaning Filter

Categories : Screen Changers / Filters

Quality Boosting & Cost Saving The two scrapers in the filter remove the residues filtered from the surface of the special precision processed screen. Then, they are emitted from the bottom scr...

Manual Screen Changer

Categories : Screen Changers / Filters

Extrusion Manual Screen Changer is able to filter out most of the impurity of polymer and improve the quality of film. Furthermore, it is also an ideal solution to shorten the downtime and reduce t...

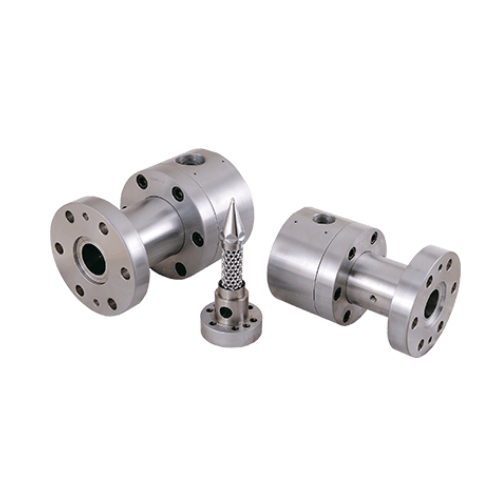

Durable Screen Changer

Categories : Screen Changers / Filters

Durable Screen Changer, which also called Candle Type Screen Changer is a functional device. It increases the pressure to filter out the impurity of polymer to increase the quality of film. It is a...

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

Categories : Screen Changers / Filters

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

Screen Changer

Categories : Screen Changers / Filters

HYDRAULIC SLIDE PLATE Hydraulic system, easy for operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : for extrusion products such as sheet an...