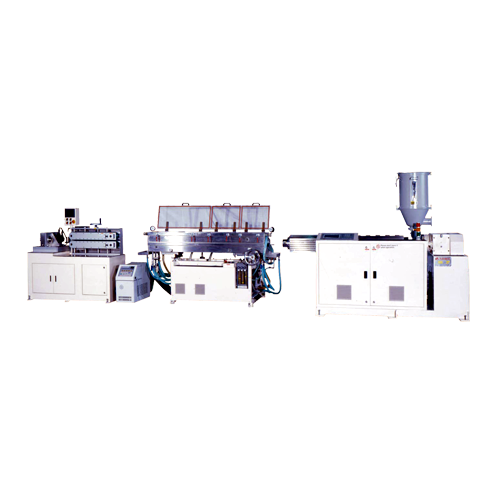

Two-Layer PE Tube Extruder & Cutting Machine EDC-08-02

Categories : Tube Heading Machine

-Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) -The temperature controllers of different materials can be controlled individually. In this way, we can find out...

Fully Automatic Heading Machine (RIH-40-04 )

Categories : Tube Heading Machine

RIH series makes shoulder for PE tube and laminated tube. It runs fully automatically by touch screen and designs the safety mechanism for operators. There is an orientation system for I-Mark so it...

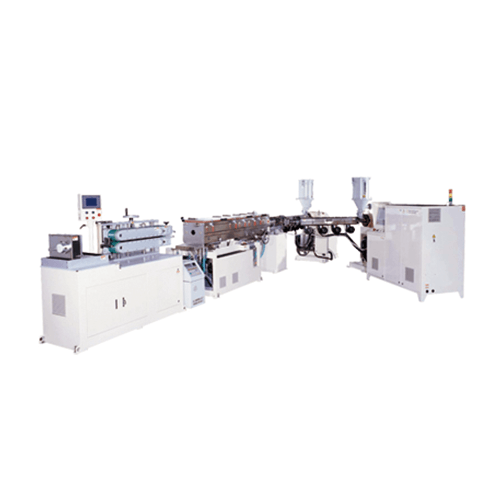

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Tube Heading Machine

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development...

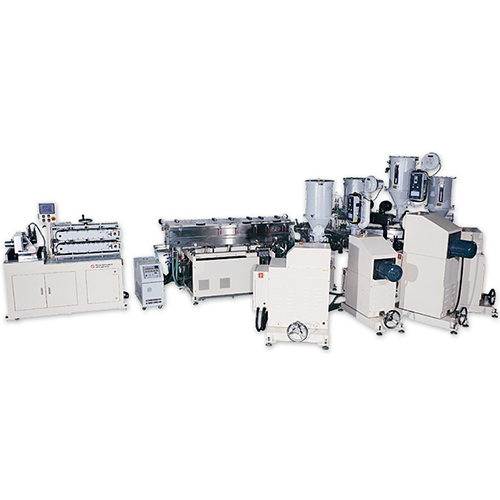

Multi-Layer PE Tube Co-Extrusion Line EDC-08-05

Categories : Tube Heading Machine

Plastic material has its own characters. In co-extrusion system. We use and combine several kinds of materials, therefore, the characters of single layer tube can't compete with the complex cha...

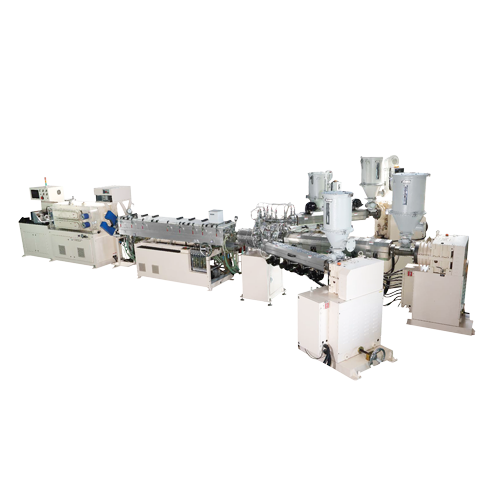

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Tube Heading Machine

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterp...