Mold Changing Systems

Mold changing systems are designed to reduce downtime and improve efficiency in production lines that require frequent mold or die changes. By streamlining the mold setup process, these systems enhance safety, precision, and production flexibility for injection molding and stamping operations.

PRM-Taiwan offers a variety of mold changing solutions from Taiwanese suppliers, including Mold Carts, Quick Die Change Systems, and Quick Mold Change Systems. These tools help manufacturers reduce changeover time, boost productivity, and support high-mix low-volume manufacturing environments.

Quick Die Change System

Categories : Quick Die Change System

Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system auto...

Quick Mold Change System

Categories : Quick Mold Change System

• Decreased mold change time • Fully customizable to fit a wide range of machines • Safer operations • Reduced labor costs • Easy changeover for small batch runs mold cast...

Die / Mold Cart System

Categories : Mold Carts

• Fully automated die or mold changing • High precision die or mold placement • Increased safety and efficiency • Can serve multiple production lines at once • Multiple...

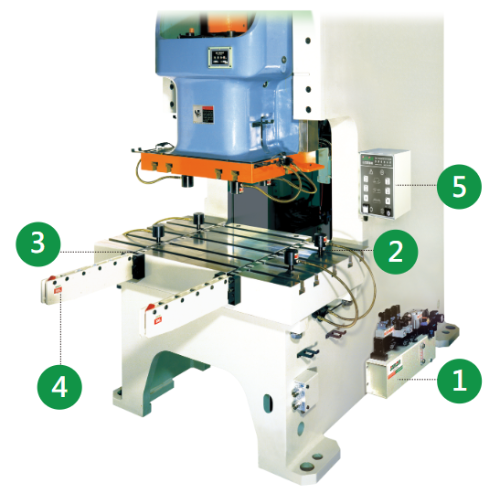

Quick Change Die System

Categories : Quick Die Change System

It is an era for making high frequency of die changing with multiple patterns and small quantity. In order to save die changing time and ensure operational safety, it is just in time to apply Quick...

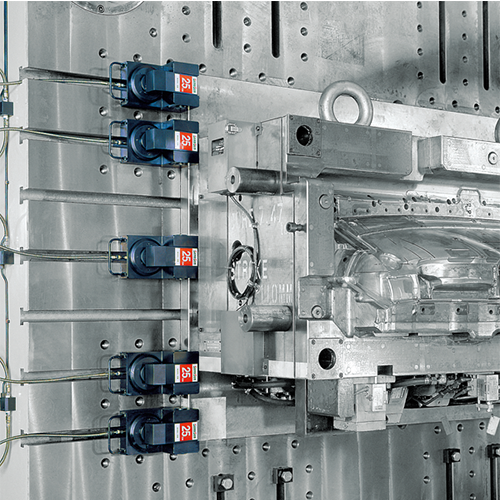

Mold Changer System

Categories : Quick Mold Change System

FEATURES Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival and positioning in the process of mold mov-in...

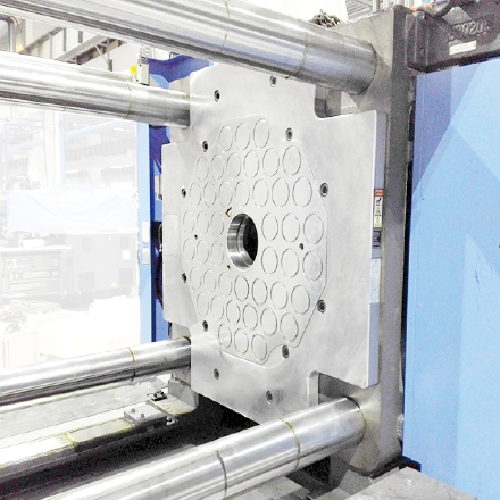

Magnetic Clamping System

Categories : Quick Mold Change System

Electro-permanent magnetic quick mold change system is perfectly for 50~4000 Tons injection molding machines.The latest magnetic structure and outstanding design of magnetic circuit achieves a 20% ...

Mold Flip Device For Press

Categories : Quick Mold Change System

Mold Flip device using electric hydraulic motor, move up-down and flip mold through hydraulic power. Using the Mold Flip device can raise work efficiency and also reach zero accident happens. If po...

Quick Mold Change System

Categories : Quick Mold Change System

It is an era for making high frequency mold change with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to...