Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines.

Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

FORWELL Q.D.C.S quick die change system for punch presses provides a variety of quick die change special components for various punch dies. The use of this system can not only reduce the idle time of punch presses, but also greatly promote the improvement of production capacity, so as to achieve more production management. rationalization.

This quick mold change system has multiple functions and can be used under different production conditions. For example, when a large number of different types of products need to be produced in a short period of time, using such a system can save a lot of time and effort. At the same time, this system can also help enterprises realize the automation of production lines, reduce labor costs and improve production efficiency. In addition, this kind of system can also help enterprises improve the quality of products and reduce waste and loss in the production process. Therefore, it is a very wise choice to use this quick mold change system, which can help enterprises better cope with market competition and changing consumer demands.

- It can provide a variety of special components for quick die change for various punch dies

- Not only reduce the idle time of the punch press, but also greatly promote the improvement of production capacity and realize more rational production management.

- It can be used under different production conditions

- Save a lot of time and effort, especially when a large number of different types of products need to be produced in a short period of time

- It can help enterprises realize the automation of production lines, reduce labor costs and improve production efficiency

- It can help enterprises improve the quality of products and reduce waste and loss in the production process

- It is a very wise choice to use this quick mold change system, which can help enterprises cope with market competition and changing consumer demands

| Before | After |

| 01 Manual Operation | Automation. Higher work efficiency and less waste of manpower. |

| 02 While Die/Mold changing, it takes long time and manpower to tighten. | When changing molds, just press the operation button on the operation panel to lock quickly and easily. Great time saver. |

| 03 The tightening force will be different by different operators. | The clamping force is the same. Increased safety. |

| 04 Operators waste much manpower, increased injury happened. | By control panel, operators save manpower and decrease injury happened. |

| 05 No alarm notification while the screws are loosing. | With alarm device, the machine will stop immediately. |

The Forwell Quick Die Change System boosts the efficiency and safety of small to large scale pressing operations. For the system configuration best suited to your needs, please refer to the following sections.

| Basic clamp selection Select TX Clamp when die U-slots are provided. Select TY Clamp when die U-slots are not provided. |

Determine the required clamping force Clamping force = 20% of Press Tonnage |

Distribution of upper to lower die clamping force Higher press tonnage for the upper die. Ratio of upper clamping force to lower clamping force=3:2 (Single die clamping force)=(upper or lower die clamping force)÷number of clamps |

How to determine the number of clamps required

Determine the number of clamps according to the dimensions and configuration of your die and the T-slot arrangement on the press. |

| Screw Bolt | M16 | M18 | M20 | M24 | M30 | M38 |

| Clamping Force(tf) | 3 | 4 | 5 | 10 | 15 | 20 |

Determine the number of clamps according to the dimensions and configuration of your die and the T-slot arrangement on the press.

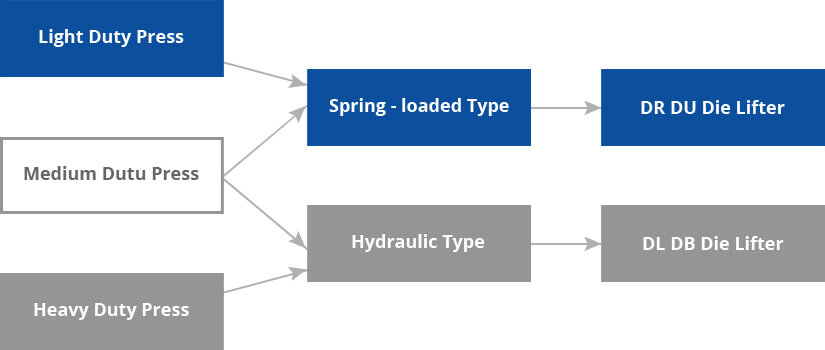

Select Spring-Loaded of Hydraulic Die Lifters

Select Spring-Loaded (DR DU) or Hydraulic (DL) Die Lifters according to the press tonnage, die weight and the die positioning accuracy required.

| Selection criteria |

|

Die Lifter

|

|

Lift Capacity

|

|

Maximum Die Lifter Load Weight

|

|

U-slot Size

|

|

Accessories

|

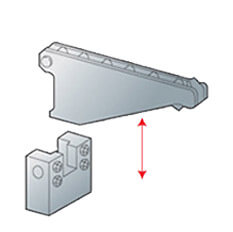

RC Detachable Type

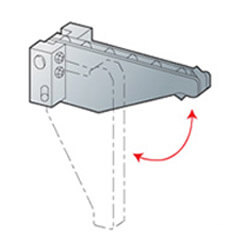

RD Drop-down Type

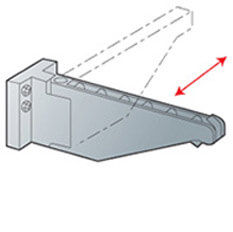

RE/RF Folding Type

| Selection criteria |

|

Die Dimensions

|

|

Maximum Die Arm Load Weight

|

|

Type

|