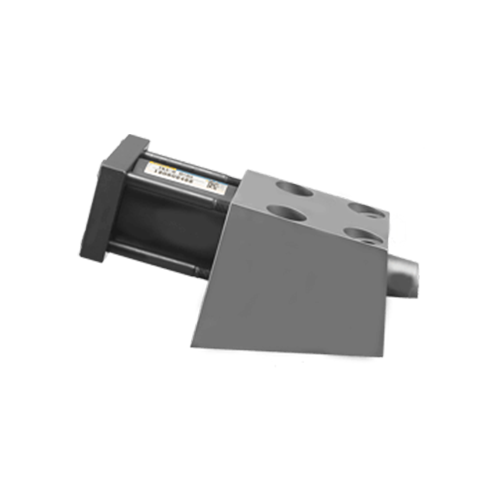

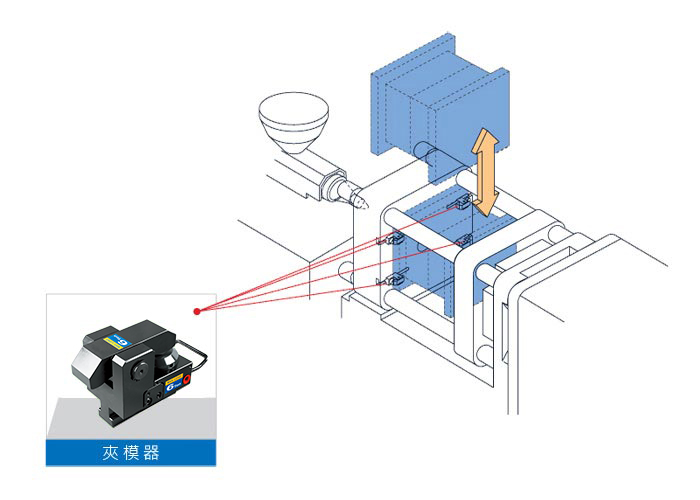

A wide range of accessories for quick mold change systems are available here, including pump models and mold clamps for various injection molding and mold casting operations. Several factors need to be considered when selecting the correct accessory, such as production volume, material properties, and budget. Also, pay attention to the size and weight of the accessory to make sure it fits your device and is safe and secure.

System planning includes purchasing a quick mold change system that suits you. It is necessary to consider the tonnage of the injection machine and the size of the mold to determine the suitable film change system. At the same time, the mold also needs to open corresponding grooves for the fixture of the mold change system. Several factors need to be considered when selecting the correct accessory, such as production volume, material properties, and budget. Also, pay attention to the size and weight of the accessory to make sure it fits your device and is safe and secure.

Finally, when using accessories, care and maintenance are also required to prolong their service life and ensure their performance remains the same.

FORWELL Q.M.C.S provides a variety of injection molding machines and die-casting machine molds with various special components for quick mold change. These components can be easily replaced and installed to make your production line more flexible and efficient. The use of this system can not only reduce idle time, but also greatly increase production capacity, thereby enhancing the competitiveness of enterprises. In addition, due to the shortened mold change time, your production management will be more rationalized, and you can better grasp the production progress and save costs. Not only that, FORWELL Q.M.C.S products are also highly durable and stable, which can bring longer-term benefits to your business.

FORWELL Q.M.C.S special components for quick mold change have the following characteristics:

- It can be easily replaced and installed, making your production line more flexible and efficient.

- It can reduce idle time, greatly increase production capacity, and then enhance the competitiveness of enterprises.

- The mold change time is shortened, the production schedule can be better grasped and the cost can be saved.

- The product has high durability and stability, which can bring longer-term benefits to your business.

| Ton | Clamp | Pump Model | ||||

| Moving | PCS | Fixed | PCS | Total | ||

| ~ 150 | TY-2 | 4 | TY-2 | 4 | 16TON | FP6308U-□-□C |

| ~ 250 | TY-4 | 4 | TY-4 | 4 | 32TON | FP1014U-□-□C |

| ~ 350 | TY-6 | 4 | TY-6 | 4 | 48TON | |

| ~ 550 | TY-10 | 4 | TY-10 | 4 | 80TON | |

| ~ 850 | TY-16 | 4 | TY-16 | 4 | 128TON | |

| ~ 1000 | TY-16 | 6 | TY-16 | 6 | 192TON | |

Diagram of Mold Configurations

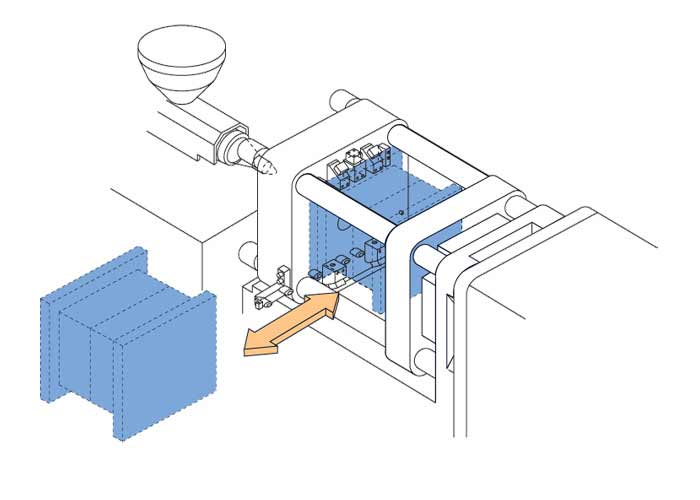

Horizontal Mold Configuration

When molds are fitted horizontally, Forwell’s Mold Cart System can be used for safe and efficient mold changing operations. With quick and efficient mold changing your whole workshop will benefit from increased productivity, safer operations and reduced labor costs.

Vertical Mold Configuration

Molds used for Mold Injection Machines and Mold Casting Machines are most commonly fitted vertically. Forwell’s Quick Mold Change System can effectively change these molds quickly and efficiently, thus decreasing idle machine time and streamlining production management.

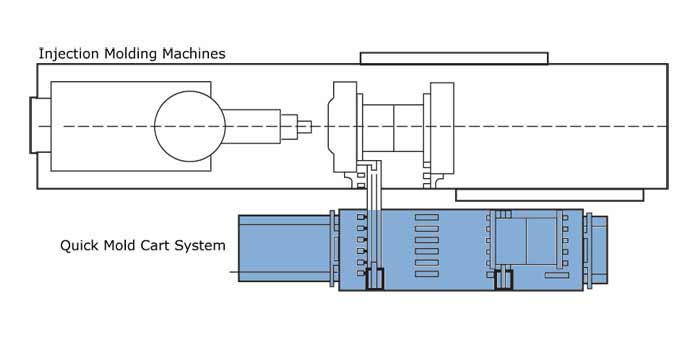

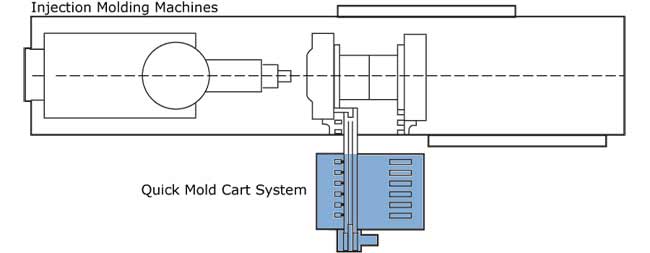

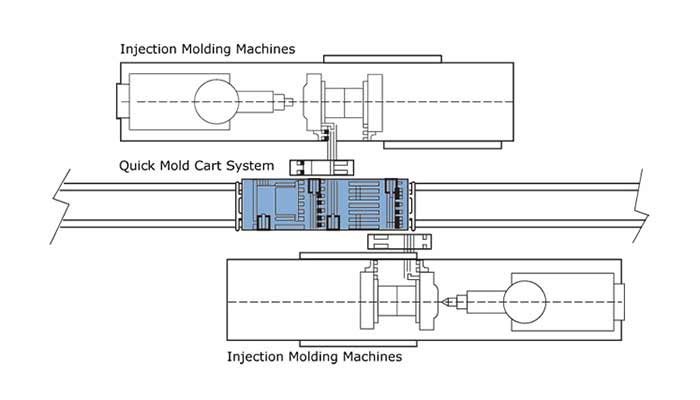

MOLD CART SYSTEM LAYOUTS

Forwell can design the most practical and efficient Quick Die Change System according to your plant layout and equipment. To further improve the efficiency of your mold changes, this system can be paired with Forwell’s Mold Cart System to create a fully automatic mold change system for your plastic injection production lines. When establishing a new production facility, please contact Forwell directly to see how beneficial a Quick Mold Change System and Mold Cart System can be for enhancing your productivity. Below you can see the different layout configurations possible when combining Forwell’s Quick Mold Change System with Forwell’s Mold Cart System:

Two Molds on a Moving Cart

Mold Cart System with a 2-mold cart for quick and automatic horizontal loading of molds.

Single Mold on a Fixed Cart

Mold Cart System with a single mold for quick and easy loading of molds.

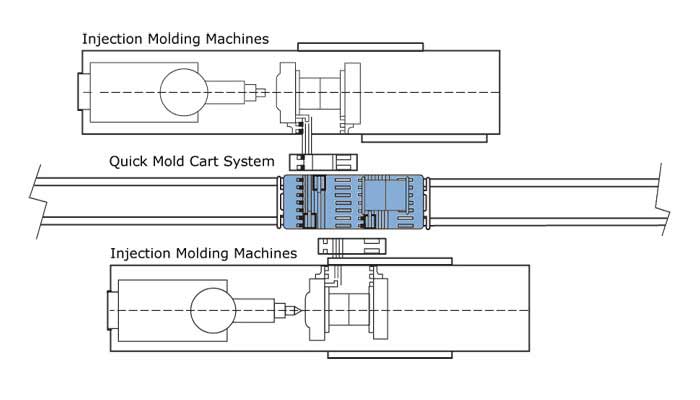

Double Sided Cart Layout

Mold Cart System that loads molds for machines positioned either side of the cart.

Machines are facing opposite directions

Machines are facing the same direction

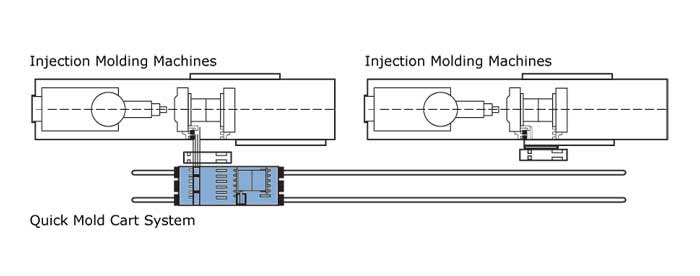

Parallel Machine Cart Layout

Mold changes are performed using a 2-mold cart that serves two or more injection molding machines that are positioned along one line. This allows for a wide application of quick mold changing.

| Before | After |

| 01 Manual Operation | Automation. Automation can make the entire process faster and more efficient, while reducing human error and fatigue |

| 02 While Die/Mold changing, it takes long time and manpower to tighten. | Just press the operation button on the operation panel, the locking time can be greatly shortened, and the production efficiency can be improved. |

| 03 The tightening force will be different by different operators. | After the introduction of the new system, the clamping force remains the same, and it can operate more stably regardless of the content of the work. |

| 04 Operators waste much manpower, increased injury happened. | Only through the operation panel, on-site personnel can not only save manpower, but also reduce the incidence of industrial safety accidents. The introduction of the new system can help improve the safety of the production environment and reduce the mental stress of personnel. |

| 05 No alarm notification while the screws are loosing. | The new system has a safety warning function. When there is a problem, the machine will automatically stop to ensure the safety of on-site personnel. |