Solution for Filament (POY, FDY) Plant

Categories : Plastic material waste recycling machine

Solution for Filament (POY, FDY) Plant

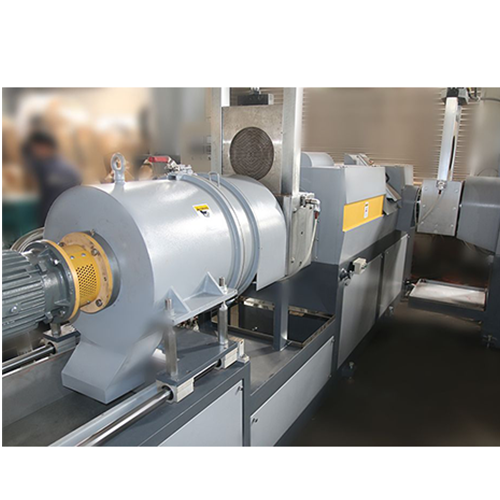

Two Stage Recycling Machine: Repro-FlexPlus

Categories : Plastic material waste recycling machine

Two Stage Recycling Machine with integrated cutter compactor. Improved degassing and filtration.

RAS UP 800

Categories : Plastic material waste recycling machine

FIMIC’s latest innovations are aimed to address the current challenges in the plastics recycling industry. RAS 800 is the new addition to the automatic self-cleaning melt filters models produ...

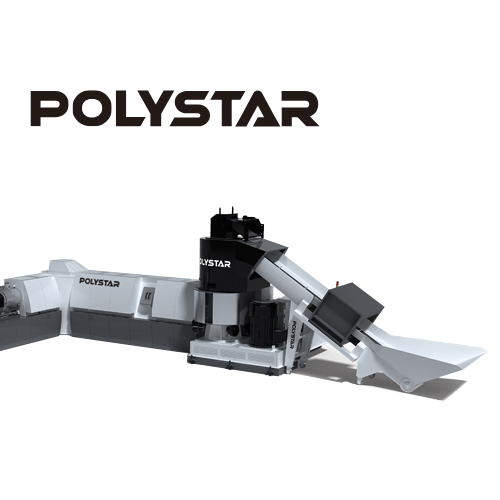

Recycling Machine - Film, Raffia, Regrind (PE/PP): Repro-Flex

Categories : Plastic material waste recycling machine

● High efficiency recycling line for post-industrial packaging film ● With cutter compactor integrated which eliminates the need to pre-cut material

Crushing Machine For Immediate Recycling System - C-200 / 250 / 300 ST

Categories : Plastic material waste recycling machine

The plastic crusher is design for plastic manufacturing. Industrial recycling and granulation of plastic. • Suitable materials include plastics such as PP, PVC, PE, PET, ABS, etc. •...

Low-Speed Crushing Machine - C-S210 / 260 / 310 / 420 SB

Categories : Plastic material waste recycling machine

● Slanted tooth rotary cutter for increased cutting power ● Produces little powder and low noise. ● Suitable for materials with high fiber content.

Success Story - Force Side Feeding Plastic Recycling Machine

Categories : Plastic material waste recycling machine

RECO-Z-125i / Force Side Feeding Plastic Recycling Machine / Washed PE Film / Taiwan RECO-Y-150i / Force Side Feeding Plastic Recycling Machine / HDPE bottle / Taiwan

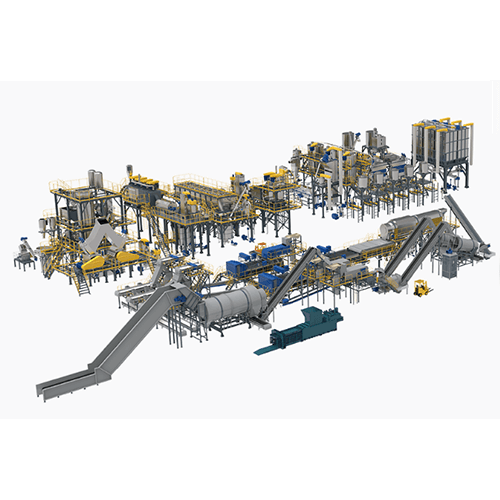

Micro Denier Filament Grade PET Bottle Washing Line

Categories : Plastic material waste recycling machine

Micro Denier Filament Grade PET Bottle Washing Line

Two Stage Force Side Feeding Plastic Recycling Machine (RECOi Series)

Categories : Plastic material waste recycling machine

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output pe...

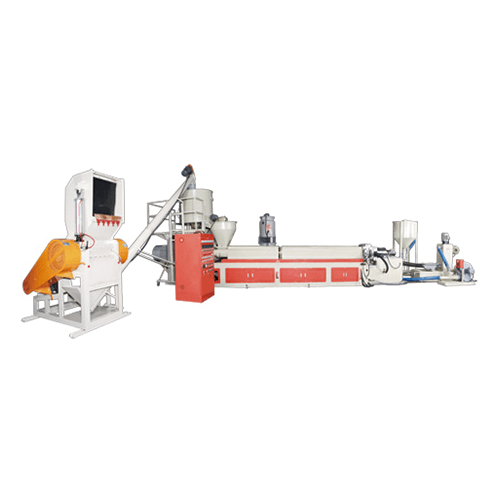

PP, ABS, PE PLASTIC WASTE RECYCLING EXTRUSION MACHINE

Categories : Plastic material waste recycling machine

ABS/PP/PE Waste Plastic Recycling Making Machine

Pelletizing & Recycling System

Categories : Plastic material waste recycling machine

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

Single Screw Squeezing Drying Machine

Categories : Plastic material waste recycling machine

With a special designed screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granul...

FILM/BAGS WASTE PLASTIC RECYCLING MACHINE : KCR-150

Categories : Plastic material waste recycling machine

Each blown film machine is equipped with an electronic length counter and an accumulated time meter. In addition, all main output shafts are precision ground for exceptional stability and quiet ope...

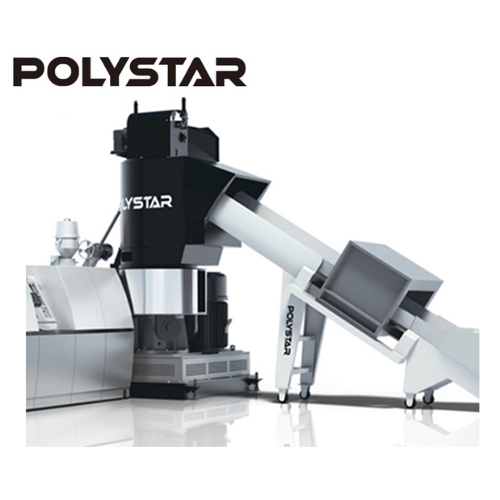

Two Stage Cutter Compactor Plastic Recycling Machine (KRIEGERi Series)

Categories : Plastic material waste recycling machine

Compacting & feeding The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for ...

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

Categories : Plastic material waste recycling machine

Water Cooling Type Plastic Film Recycling Machine (GSR-85)

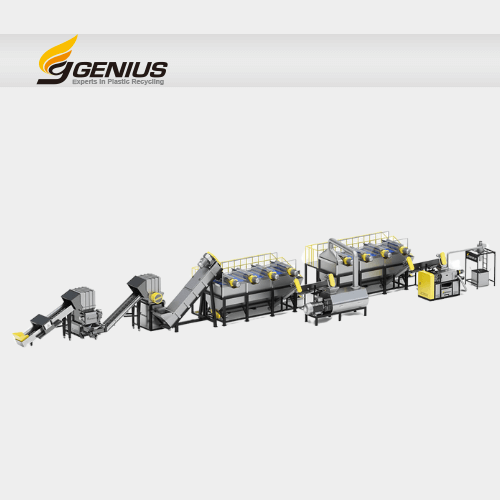

Film Washing Line

Categories : Plastic material waste recycling machine

Solution for different level of plastic films The film washing line equipped crushing, washing and drying units. Which allowing to process different dirty levels of materials, from agriculture film...

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic material waste recycling machine

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic material waste recycling machine

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipmen...

Horizontal Centrifugal Dryer

Categories : Plastic material waste recycling machine

Suitable for washed plastic scraps Good at water removal. The residual moisture after drying could be around 1-3%. Maximum capacity could reach 1 ton/hr for plastic scraps drying. With st...

EPS Pastic Waste Recycling Machine

Categories : Plastic material waste recycling machine

EPS PLASTIC WASTE RECYCLING MACHINE

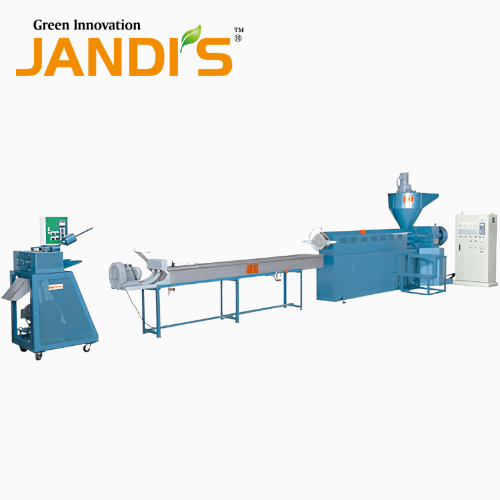

Instant Recycling System

Categories : Plastic material waste recycling machine

In the past, operators throw away the sprues or waste material in small amount or wait for collecting them in big amount to reuse. However, that may be stuck dust by static electricity become too b...