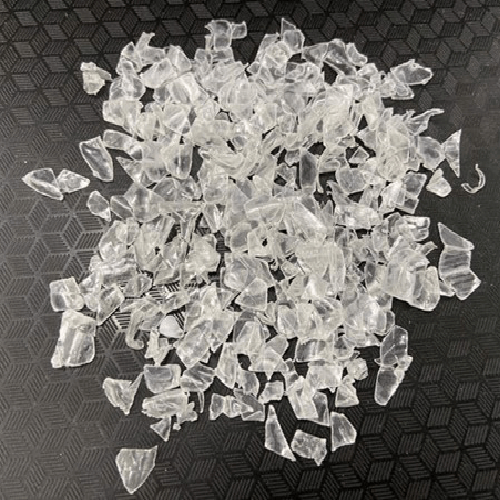

BoReTech started to provide PET bottle flakes to the recycled filament production factory for spinning in 2007. It has a deep understanding of the quality standards of filament spinning by PET flakes and has accumulated a lot of relevant experience in regenerated filament spinning industry. Combining with local equipment supply chain in China, BoReTech's engineering capabilities, international project implementation experience, BoReTech can provide customers with a complete solution of filament production line.

The experience in the production and manufacturing of recycled filament-grade PET chips at the BoReTech PET recycling factory in Taiwan have solved the biggest problem in the production of Eco fine-denier filaments and ensured the stability of product quality.

1. The output capacity of the production line can be customized according to the customers.

- The output capacity range: 2TPD-100TPD/Line, the denier can achieve 0.9DPF.

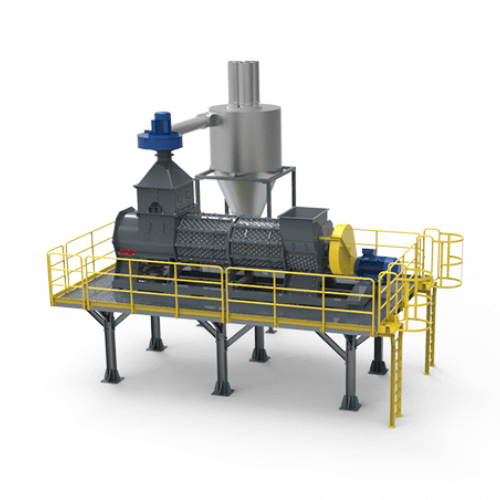

2. A complete PET bottle recycling line, a large-capacity PET flake storage system, and a batching system are collocated to the filament production line to achieve the best spinnability.

3. The color dosing system can realize the simultaneous production of multiple colors.