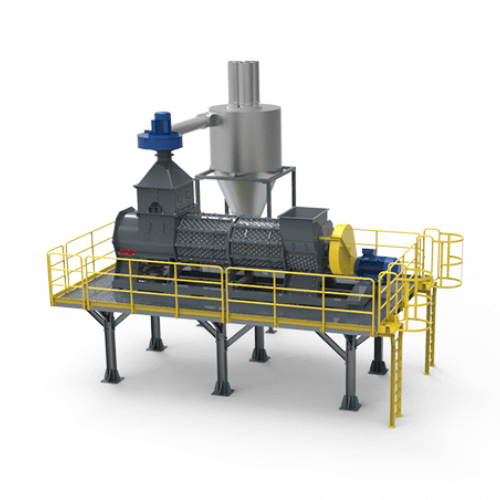

BoReTech supplies two types of PET bottle pre-washing machines, continuous type, and batch type. The biggest feature of continuous bottle pre-washer is that it owns an automated water circulation system and continuous input feeding, then uses high-temperature chemical water to wash bottles. This kind of washing removes labels, dirt, sands, glues, rubbers, metals and other impurities on the bottles' surfaces. The impurities separation rate is over 90%. The supplementary chemical water recycling system achieves the completed separation between chemical water and bottles, and prolong the service life of the chemical water and saves additive cost.

Batch-washing ensures that PET bottles have sufficient time soaking in chemical water, it will be applied to recycle oil bottles well.