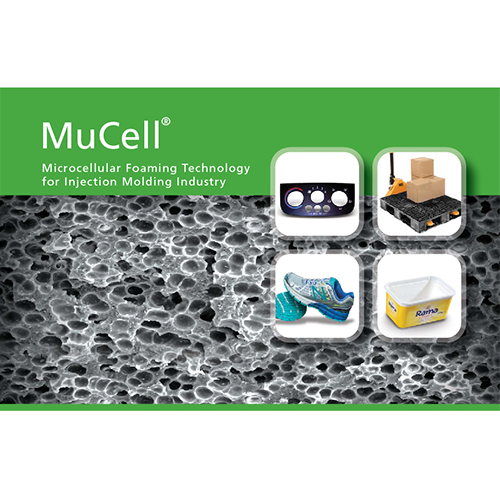

Foaming Injection Molding system

Categories : Outsole/Midsole Foamer

Under the drive of lightweight and environmental awareness, using new technologies to reduce the product weight and the impact on environment has received increasing attention. “Foaming injec...

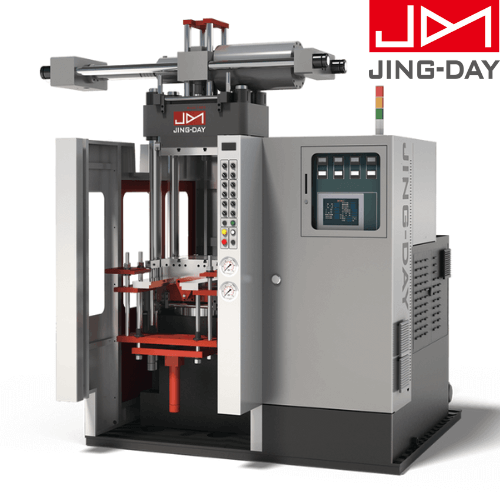

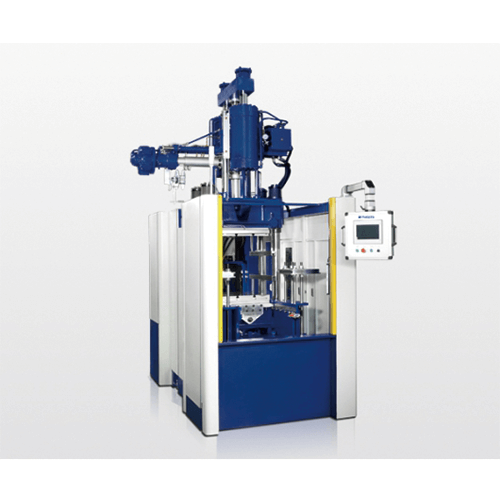

KR Series Plastic Injection Molding Machine (STANDARD)

Categories : Outsole/Midsole Foamer

Efficiently inject large work pieces with our vertical injection molding machine. Robust structure, user-friendly layout. Customize functions for optimal performance.

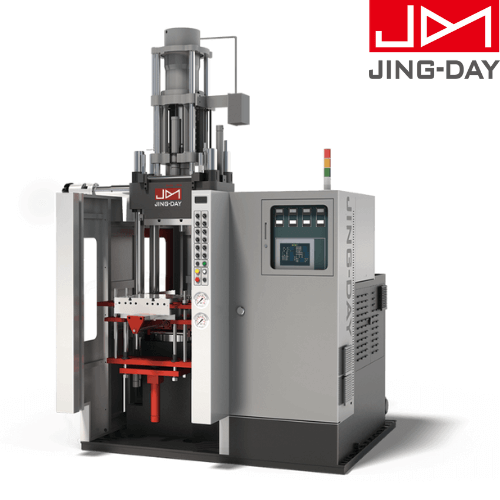

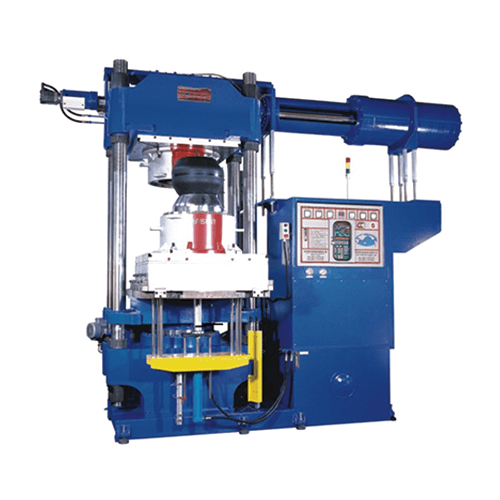

Rubber Injection Molding Machine - Direct Clamping JD-RH series

Categories : Outsole/Midsole Foamer

Machine for natural, synthetic, oil resistant,heat resistant and reclaimed rubber.

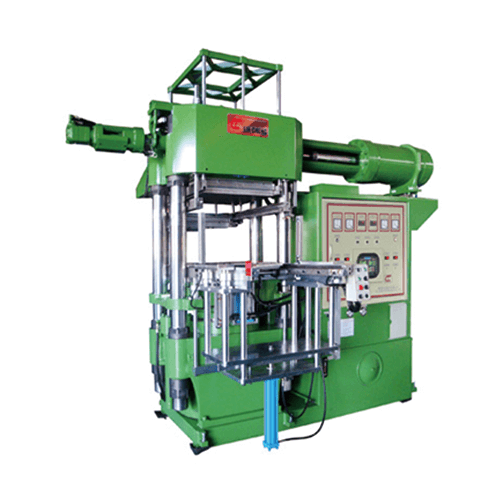

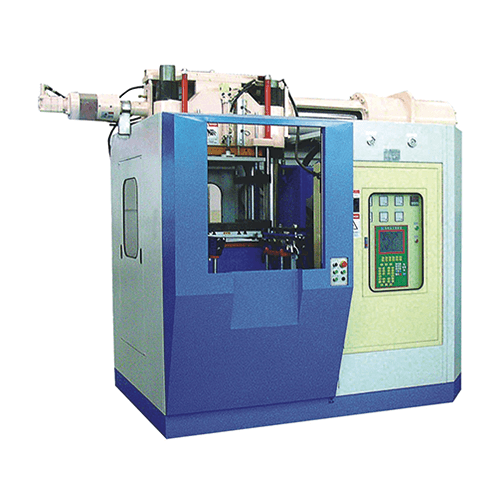

Rubber Injection Molding Machine (Horizontal) JD-RH horizontal series

Categories : Outsole/Midsole Foamer

Ideal for the production of natural & synthetic rubber, oil & heat resistant rubber, and reclaimed rubber.

Rubber Injection Molding Machine - Direct Clamping JD-RH series

Categories : Outsole/Midsole Foamer

Machine for natural, synthetic, oil resistant,heat resistant and reclaimed rubber.

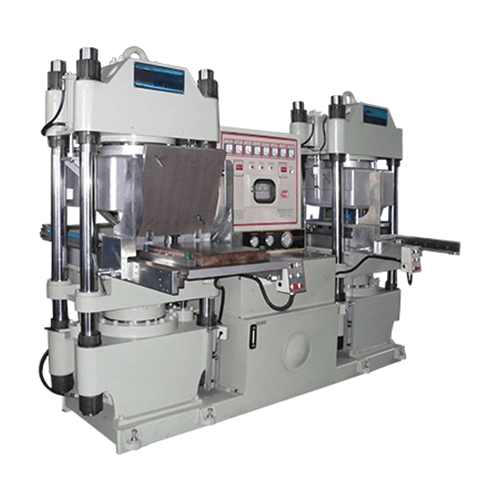

Rubber Injection Molding Machine - Indirect Clamping JD-RL series

Categories : Outsole/Midsole Foamer

Machine for natural, synthetic, oil resistant, heat resistant and reclaimed rubber.

2RT Mold-Open None Runner-Waste Rubber Injection Molding Machine

Categories : Outsole/Midsole Foamer

2RT Mold-Open None Runner-Waste Rubber Injection Molding Machine Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rub...

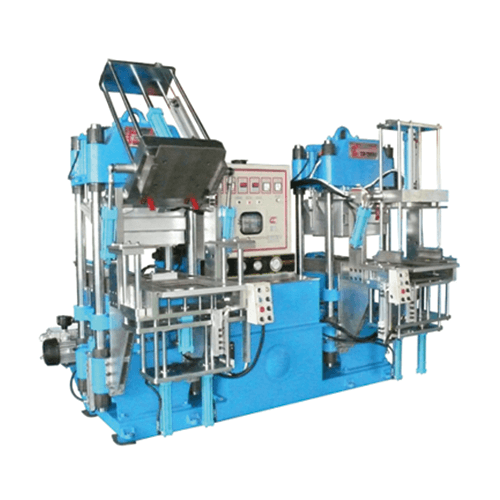

Double Decker Compression Forming Machine (Down Stroke)

Categories : Outsole/Midsole Foamer

Clamping force: 150 ton Max. surface pressure for product: 600 kg/cm2 Well mixed auto-feeding. Transparent window to check remaining material in the material barrel. Safety protection: light curtai...

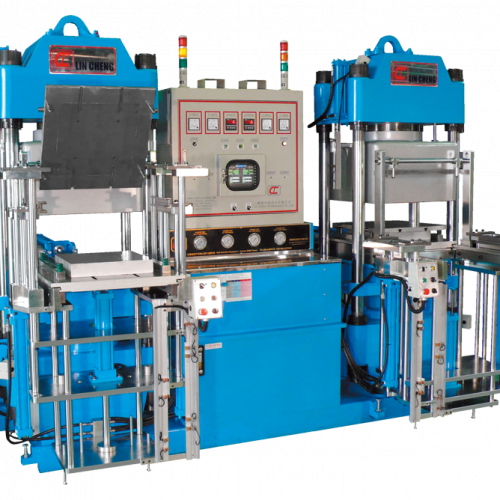

Double Decks Shuttle Type Compression Molding Machine

Categories : Outsole/Midsole Foamer

Optional to use either single mold or two molds in production and shuttle for both sides.

J- Frame Rubber Injection Molding Machine (F.I.L.O.)

Categories : Outsole/Midsole Foamer

●Simplicity in material preparation. Flexibility in the production of complicated product. ●Compound with plasticizing process and temperature controlling pre-heating, decrease curing time and incr...

3RT Mold-Open Rubber/Silicon Vacuum Compression Molding Machine VCC-D3

Categories : Outsole/Midsole Foamer

● The 3RT surpasses the traditional top opening mold that can be used for triple or four molds with the design of opening mold and pushing out the mold in between. ● The opening mold can be adjuste...

4RT Mold-Open Oil-Seal Vacuum Compression Molding Machine VOCC-D3W

Categories : Outsole/Midsole Foamer

Design for machine frame The machine frame is made of steel plates through assembly. It is suitable for the production of oil seals. Design for loading/unloading molds Abrasive components are insta...

2RT Mold-Open Rubber/Silicon Vacuum Compression Molding Machine -VCC-D2

Categories : Outsole/Midsole Foamer

This type of machine is multi-functional, because it is suitable to be used for top opening double or triple molds. Hydraulic system Designed by proportional pressure and flow ratio, which is stead...

Horizontal Rubber Injection Molding Machine (FIFO)

Categories : Outsole/Midsole Foamer

Horizontal structure with ergonomic design. Equipped with auto de-molding device for finished products can be dropped by its own weight, and improve auto production process. Compiled with OPC UA st...

Patent Rail Mold-Open Rubber/silicone Compression Vacuum Molding Machine VCC-DP

Categories : Outsole/Midsole Foamer

Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber.

Sole Making Machine - YT SERIES

Categories : Outsole/Midsole Foamer

- Vertical clamping, horizontal injection, and single-sliding which allows the operator to work more convenient.

2RT Mold-Open silicone Injection Molding Machine

Categories : Outsole/Midsole Foamer

Features Mold opening design The 3RT surpasses the traditional top opening mold that can be used for the triple or four molds with the design of the opening mold and pushing out the mold in the bet...

2RT Mold-Open Tire Bladder Rubber Injection Molding Machine IRH-S2

Categories : Outsole/Midsole Foamer

Mold opening design The 2RT surpasses the traditional top opening mold that can be used for the double or triple molds with the design of the opening mold and pushing out the mold in the between. T...

CE Certificate Rubber Injection Molding Machine

Categories : Outsole/Midsole Foamer

Material supply system A special design of two-stage material supply is adopted. It expels bubbles out of the raw material in the most effective way and there is no dead material.