-

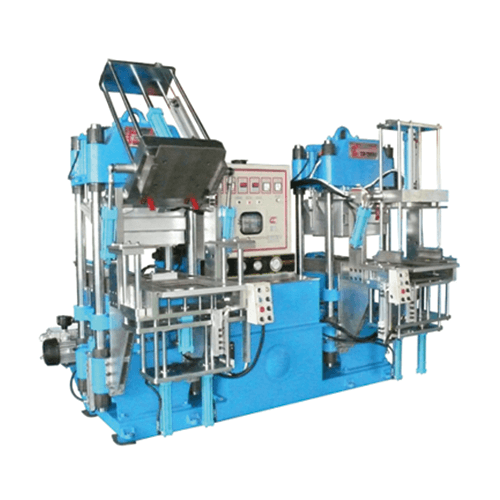

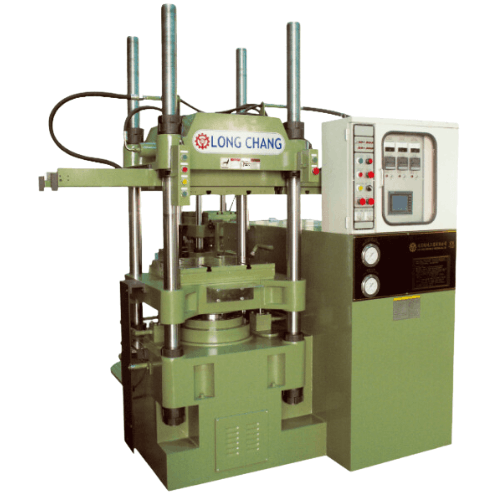

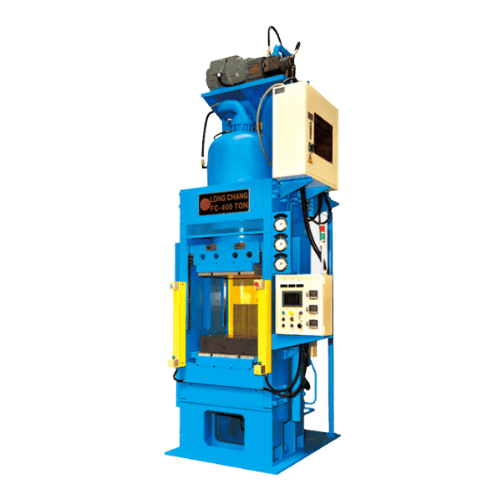

Design for machine frame

The machine frame is made of steel plates through assembly. It is suitable for the production of oil seals.

-

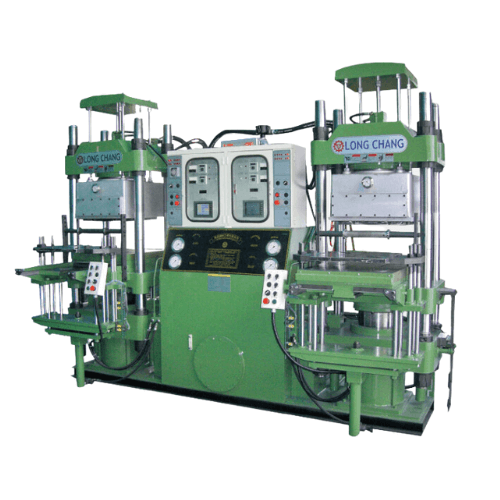

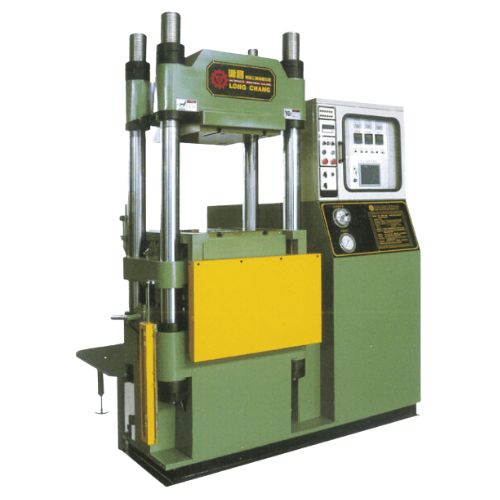

Design for loading/unloading molds

Abrasive components are installed on the frame for loading/unloading molds. It can be frequently used and it’s positioning is very accurate.

-

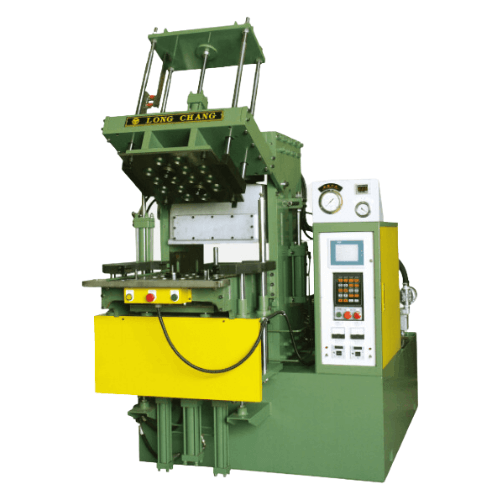

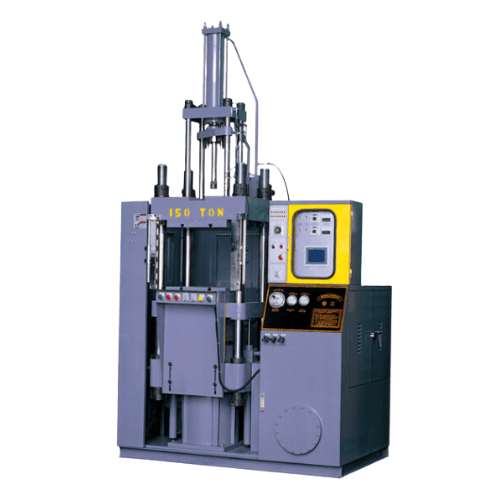

Design for vacuum room

A vacuum gate can be opened or closed very quietly and smoothly. The tightness is excellent and it is capable of being high percentage of vacuum.

-

Design for oil tank

The vacuum room and the oil tank are separated to make oil seals more durable.

-

Design for final products

Two openings are designed for final products, top and bottom. The operation is easy and the production speed is very fast.

-

Maintenance

All positioning switches are installed outside the vacuum room. It becomes more durable and it is easier to perform the maintenance work.

-

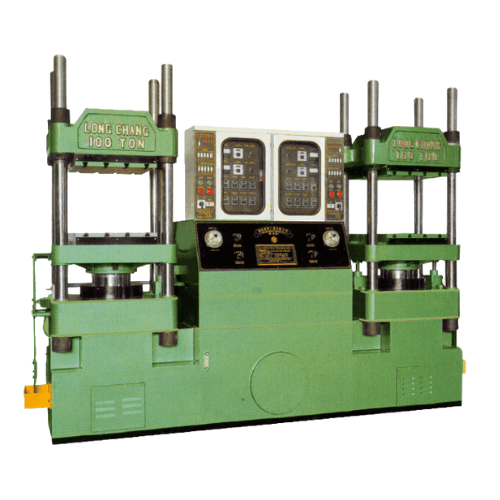

Oil system design

Each oil system is designed respectively. Two shafts can be operated simultaneous.

|

Diameter of piston (mm) |

225 |

250 |

300 |

400 |

| Clamping force (ton) | 80 | 100 | 150 | 250 |

| Stroke (mm) | 200 | 200 | 200 | 200 |

| Heating platen (mm) | 250*300 | 350*400 | 450*480 | 570*610 |

| Mold board size (mm) | 290*320 | 390*420 | 500*520 | 620*620 |

| Horse (hp) | 5 / 10*1 | 7.5 / 10*1 | 10 / 15*1 | 10 / 15*1 |