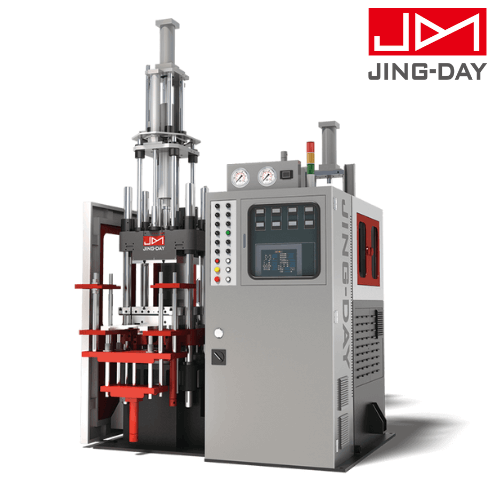

Special Purpose Machine - Silicon Injection

Categories : Liquid Silicone Injection Molding Machine

Special Purpose Machine Vertical mold clamp with horizontal injection with long closing and opening stroke, ideal for injection of large work pieces.

LIM、LSR (Liquid Silicon Rubber) Vertical Press (Rotary/Shuttle)

Categories : Liquid Silicone Injection Molding Machine

● Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. ● Increased ...

Silicone Injection Molding Machine - YH Series

Categories : Liquid Silicone Injection Molding Machine

One person for operation to saving cost.

Vertical Liquid Silicone Rubber Injection Molding Machine

Categories : Liquid Silicone Injection Molding Machine

Precision Vertical mold clamping system (Parallelism/ flatness: 0.02/100 mm) with heavy-duty tie-bars works greatly to extend machine & mold life and reduce flash of product.

Bait Making Machine - YH Series

Categories : Liquid Silicone Injection Molding Machine

Use plunger-type material less barrel, material is silicone.

Custom Vertical LIM LSR Injection Moulding Machine

Categories : Liquid Silicone Injection Molding Machine

Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. Increased prod...

LIQUID INJECTION MOLDING

Categories : Liquid Silicone Injection Molding Machine

Liquid Injection Molding (LIM) and Transfer Molding are preferred processes for manufacturing solid silicone rubber items used in a wide range of applications such as medical equipment, waters...