Can’t find what you are looking for?

Fill in the inquiry form below, let us know about your requirements.

Our specialists will forward your inquiry to the related suppliers accurately.

Stay tuned, check your email box for notifications about your inquiry status.

Sign up for free, track your inquiries, contact your favourite suppliers directly.

NOTICE

• To find suppliers for Machinery/Components, please fill in the RFQ below and tick in the type of product you are looking for on the "Types of Products" buttom.

• For Cooperations, Media exchanges, or feedbacks, please contact us by email.

• For Cooperations, Media exchanges, or feedbacks, please contact us by email.

Please Select Category

- Auxiliary Equipment and Integrated Automation

- Blow Molding Machines

- Extruders and Extrusion Lines

- Finished/Semi-finished Products

- Injection Molding Machines

- Molds and Dies

- Packaging Machinery

- Parts and Components

- Plastic Converting Machines

- Plastic Recycling & Material Processing Machinery

- Printing Machinery

- Raw Materials & Additives

- Rubber Processing Machinery

- Shoe Making Machinery

- Thermoforming Machines

Main Category

Mid Category

Sub Category

Please tick the category you are interested in, and then press the “Save” button down the page to proceed.

Auxiliary Equipment and Integrated Automation

Control Equipment,

Cutting Machines,

Surface Treatment Equipment...

Blow Molding Machines

Automatic Blow Molding Machines,

Extrusion Blow Molding Machines,

Injection Blow Molding Machines...

Extruders and Extrusion Lines

Blown Film Extruders,

Extrusion Lines For Pipes and Profiles,

Film and Sheet Extrusion Lines...

Finished/Semi-finished Products

Fibers,

Films,

Profiles...

Injection Molding Machines

Automatic Injection Molding Machine,

Horizontal Injection Molding Machines,

Vertical Injection Molding Machines...

Molds and Dies

Extrusion Dies / Dies Heads,

Injection Molds,

Thermoforming Molds...

Packaging Machinery

Capping Machines,

Sealing Machines,

Shrink Sleeve Machinery...

Parts and Components

Gearboxes,

Pumps,

Screws and Barrels...

Plastic Converting Machines

Bag Making Machine by Applications,

Industrial Knitting Machines,

Slitters and Rewinders...

Plastic Recycling & Material Processing Machinery

Granulators,

Plastic Pelletizer Machines,

Plastic Waste Recycling Machines...

Printing Machinery

Flexographic Printing Machines,

Hydrographic / Water transfer Machines,

Rotogravure Printing Machines...

Raw Materials & Additives

HDPE Resin,

PA(Polyamide) /Nylon,

TPE (Thermoplastic Elastomer)...

Rubber Processing Machinery

Compression Molding Machines,

Dispersion Kneaders,

Silicone Injection Molding Machines...

Shoe Making Machinery

Rotary Type Shoe Injection Molding Machines,

Shoe Sole Making Machines,

Sport Shoe Making Machines...

Thermoforming Machines

Foaming Machinery,

Pressure Forming Machines,

Vacuum Forming Machines...

E-News

Continuous Innovation is Chi Chang's Promise to Customers - Verticalizing Stretching Units Saves 20% Space and Labor Costs

The extruder is the type of plastic and rubber machinery that values customization the most. It's not just about catering to customer needs through changes, but also proactively seeking innovations in line with changing times. This allows the machinery to perform at its highest efficiency, helping customers achieve optimized production while striving to reduce costs for maximum profitability.

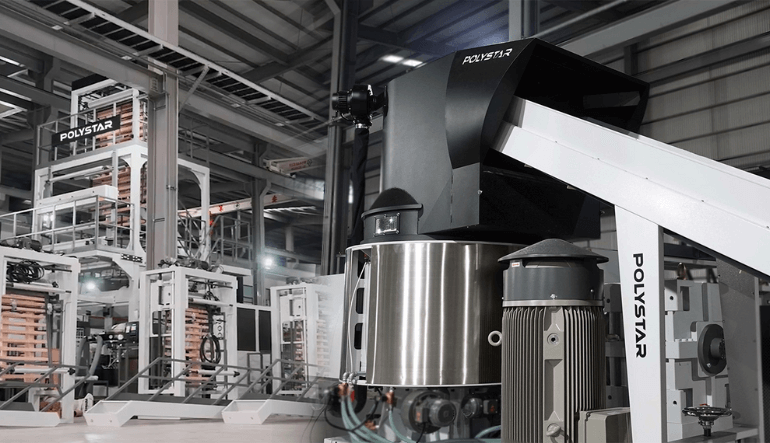

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

Plastic Recycling Hero Behind the Scenes, Geording Machinery Becomes a Trusted Manufacturer with Customization Capabilities

Plastic waste recycling has long been a symbol of green sustainability. With the rapid advancement of recycling technologies, applications have become increasingly diverse and abundant. The World Economic Forum predicts that by 2030, the global circular economy will reach $4.5 trillion. Internationally, there are new applications emerging, such as environmentally friendly building materials made from PET bottle bricks and eyeglass materials made from discarded fishing nets. Coca-Cola Taiwan has also invested significant research and development efforts, spending seven years to develop products using 100% recycled plastic bottles, setting a new milestone in plastic recycling applications.

Blog

It's Record Breaking! 211,928 Visitors for the First 2 Days!

CHINAPLAS 2024 welcomed a record breaking of 211,928 visitors for the first 2 days. Among them, 44,242 came from overseas, comprising approximately 21% of the total visitors. Day 2 alone witnessed 118,687 visitors, marking a new height for single-day attendance. Of these, 24,862 were overseas visitors (~21%), establishing another new record for the daily overseas visitor no.

Path to a Greener Tomorrow── Chyi Yang's CFV Solutions of Precision and Sustainability

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

2024 PRM Spotlight Plan: Monthly Success Stories of Taiwanese Suppliers

In this article, we delve into the "Spotlight" plan, a monthly showcase that highlights the exemplary efforts of Taiwanese suppliers in tailoring solutions to meet customer needs, fostering innovation, and driving the industry forward. Though the export data for Taiwan machinery decreases in 2023 due to the economic recession, the excellent suppliers must be seen. And that's why PRM, as a pioneer media in the Plastic and Rubber industry, devoted itself to promoting Taiwanese brands.

Media

Preview

Company

Website

Contact Person

Position

Country

Address

Phone

E-mail

Types of Products

Comments

Attachment

*Additional Function

Would you accept we forward this inquiry to other suppliers?

*Please fill out this field

Please double check information above, especially your phone number and email address before submitting.

Experience More Functions For Free

✓Directly contact Taiwanese Supplier

✓Track the progress of your inquiries

✓Manage your previous inquiries

Start to enjoy our premium messaging system and chat with your selected suppliers!

✓Track the progress of your inquiries

✓Manage your previous inquiries

Start to enjoy our premium messaging system and chat with your selected suppliers!