Injection Molding Machines by Platen

Injection molding machines by platen structure are categorized into single platen and two platen designs. Single platen machines offer compact construction and stable movement, ideal for mass-producing medium and small parts. Two platen machines provide longer opening strokes and stable clamping for large components or multi-cavity molds. Tube heading injection machines are specialized for preforming tube heads, widely used in soft tube and pipe production.

PRM-Taiwan features a full range of platen-type machines, including Single Platen Injection Machines, Two Platen Injection Machines, and Tube Heading Injection Machines, helping manufacturers optimize equipment layout based on production needs and floor space.

Outward Toggle Type Plastic Injection Molding Machine - TWII-Series

Categories : Two Platen Injection Molding Machines

Outward Toggle Clamping a Significant Increase in Structural Accuracy of Mold Platen Benefit: High Rigidity / Highly Precise Injection, Energy Saving / Customization Plasticized Applications: Prefo...

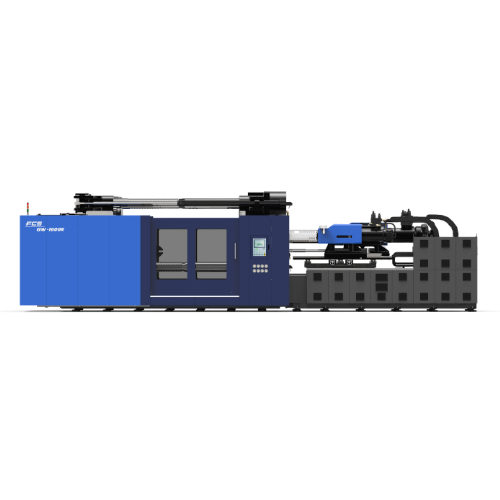

Two-Platen Multi-Component Injection Molding Machine (GW-R Series)

Categories : Injection Molding Machines by Platen

It is a newly launched large-scale two-plate multi-component injection molding machine, widely adopted in the automotive, home appliance, and furniture industries for manufacturing large two-color ...

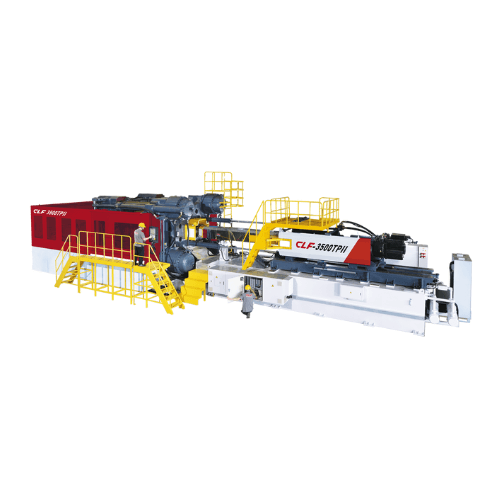

Two Platen Plastic Injection Molding Machine - TPII SERIES

Categories : Two Platen Injection Molding Machines

Unique two platen design for clamping mechanism exhibits exceptionally high speed clamping feature.

Two Platen Injection Molding Machine (LM Series)

Categories : Two Platen Injection Molding Machines

It is medium and large scale injection molding machine. It is applicable to automotive industry such as bumper and

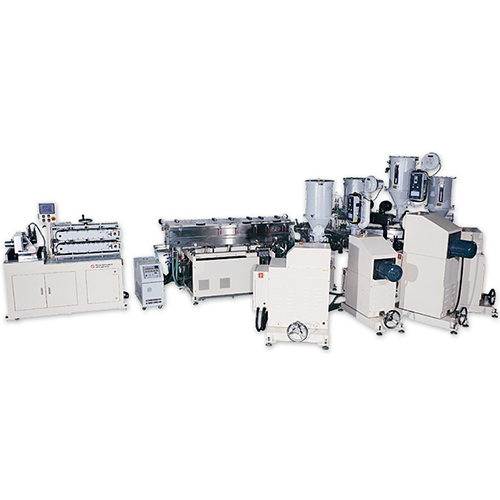

Multi-Layer PE Tube Co-Extrusion Line EDC-08-05

Categories : Tube Heading Injection Molding Machine

Plastic material has its own characters. In co-extrusion system. We use and combine several kinds of materials, therefore, the characters of single layer tube can't compete with the complex cha...

PE Tube Heading Machine SIH-30-HC

Categories : Tube Heading Injection Molding Machine

With 250 sets memory storage in the computer and the monitor which can show the operating status.Insert tubes manually and remove tubes with air blowing unit.Double heading mould for fast running.M...

Automatic Accumulator & Transfer Control System

Categories : Tube Heading Injection Molding Machine

Automatically storage functions. Available to connect with outer diameter control unit, to separate / remove defect tube via conveyor, not into accumulator. Automatically separate / remove tubes wh...

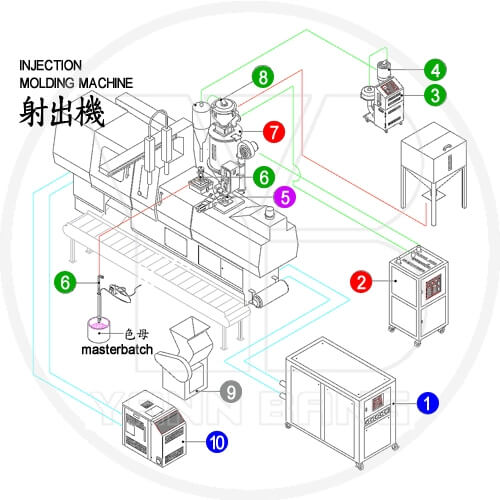

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Injection Molding Machines by Platen

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperat...

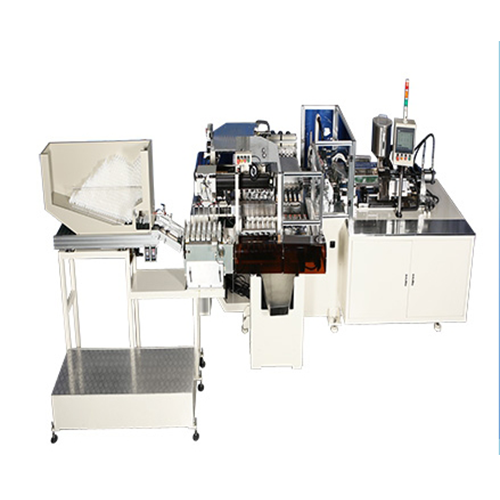

Soft Tube Injection Heading Machine RIH-60-06

Categories : Tube Heading Injection Molding Machine

Touch panel control.Suitable for both Oval and Round tubes production.Headed tube with orifice design available.Fully automatic controlling by servo motors: Loading/unloading system, Drillingorific...

Fully Automatic Heading Machine (RIH-40-04 )

Categories : Tube Heading Injection Molding Machine

RIH series makes shoulder for PE tube and laminated tube. It runs fully automatically by touch screen and designs the safety mechanism for operators. There is an orientation system for I-Mark so it...

Two Platen Injection Molding Machine NRH Series

Categories : Two Platen Injection Molding Machines

20% ~ 30% less from machine length, compare with toggle design. Less space required from a molding facility. Less space required from a molding facility. Fully automatic mold-close adjustm...

Double injection molding machine – HDC series

Categories : Two Platen Injection Molding Machines

The standard HDC series has two parallel horizontal injection unit to be able to produce a 2-color and 2 plastic material in a time to save time and increase the productivity. To equip Huarong&rsqu...

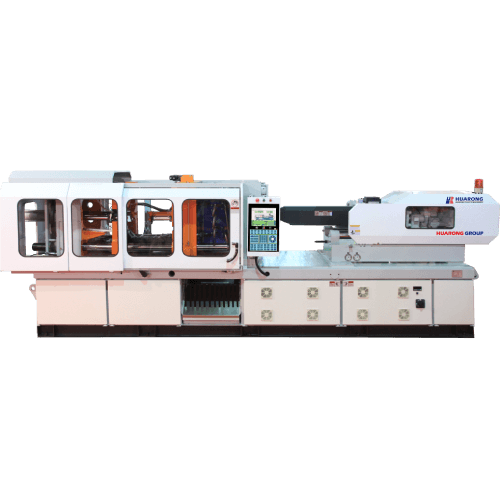

General injection molding machine – HRN series

Categories : Single Platen Injection Molding Machines

The standard HRN series is a single injection molding machine with inward toggle. With the patented groove design on the tie bar, it can support the machine to the force balance. HRN series is avai...

Dual Platen Injection Molding Machine

Categories : Two Platen Injection Molding Machines

As a large tonnage injection molding machine, it can saves up to 20% of the machine floor space. (foot print) • Automatic mould adjustment saves on mould-changing time.

Two Platens Injection Molding Machine - 400MBE to 2300MBE

Categories : Two Platen Injection Molding Machines

The actuator of the clamping force is installed on the fixed platen of the conventional two platens injection molding machine. The design of the MBE model has four sets of traveling cylinders insid...