Outward Toggle Type Plastic Injection Molding Machine - TWII-Series

Categories : Two Platen Injection Molding Machines

Outward Toggle Clamping a Significant Increase in Structural Accuracy of Mold Platen Benefit: High Rigidity / Highly Precise Injection, Energy Saving / Customization Plasticized Applications: Prefo...

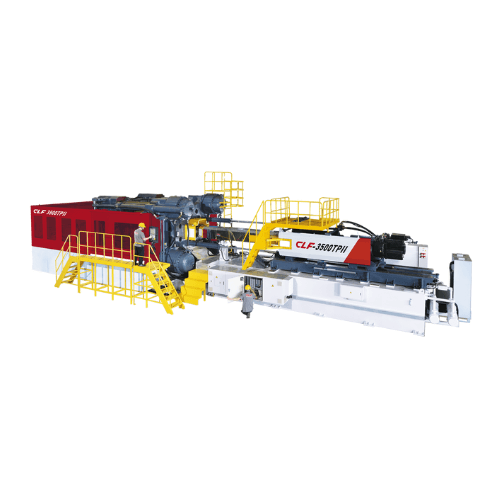

Two Platen Plastic Injection Molding Machine - TPII SERIES

Categories : Two Platen Injection Molding Machines

Unique two platen design for clamping mechanism exhibits exceptionally high speed clamping feature.

Two Platen Injection Molding Machine (LM Series)

Categories : Two Platen Injection Molding Machines

It is medium and large scale injection molding machine. It is applicable to automotive industry such as bumper and

Two Platen Injection Molding Machine NRH Series

Categories : Two Platen Injection Molding Machines

20% ~ 30% less from machine length, compare with toggle design. Less space required from a molding facility. Less space required from a molding facility. Fully automatic mold-close adjustm...

Double injection molding machine – HDC series

Categories : Two Platen Injection Molding Machines

The standard HDC series has two parallel horizontal injection unit to be able to produce a 2-color and 2 plastic material in a time to save time and increase the productivity. To equip Huarong&rsqu...

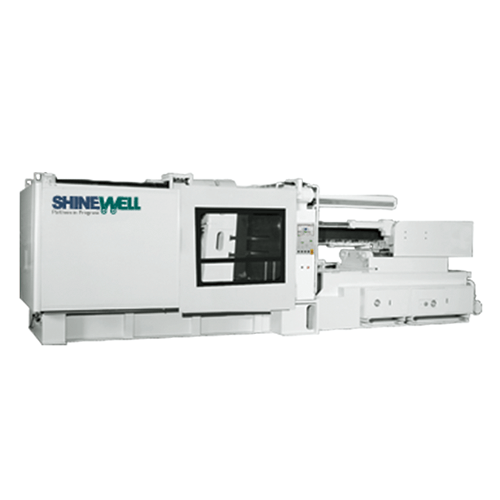

Dual Platen Injection Molding Machine

Categories : Two Platen Injection Molding Machines

As a large tonnage injection molding machine, it can saves up to 20% of the machine floor space. (foot print) • Automatic mould adjustment saves on mould-changing time.

Two Platens Injection Molding Machine - 400MBE to 2300MBE

Categories : Two Platen Injection Molding Machines

The actuator of the clamping force is installed on the fixed platen of the conventional two platens injection molding machine. The design of the MBE model has four sets of traveling cylinders insid...