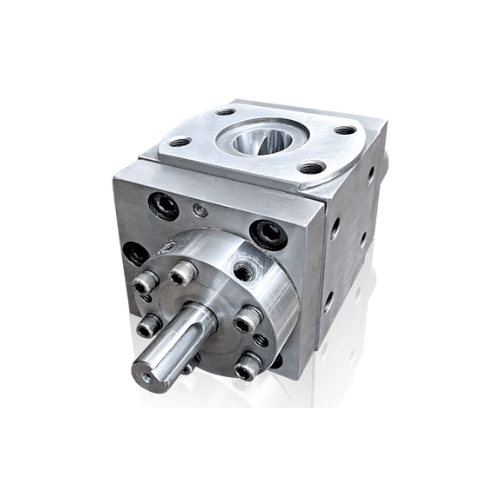

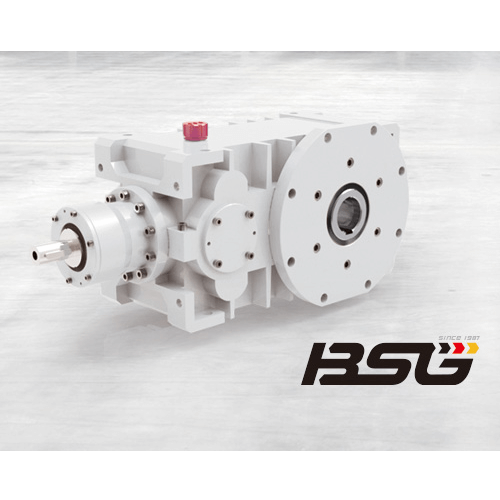

EXTRUSION GEAR PUMP

Categories : Gears

Universal Joint

Categories : Gear Shafts

(1) Angular displacement shaft up to 15 degrees (2) High loading capacity (3) Flexible length (4) Three types selection: Light load, Medium load, Heavy & Super heavy load cases of use

Precision Gears

Categories : Gears

(1) Custom Design, double check by Germany KLINGELNBERG P150 MEASURING TRIAL EQUIPMENT to optimize its overall quality and precision. (2) Follow ISO 9001-2008 version, UT, MT testing are available ...

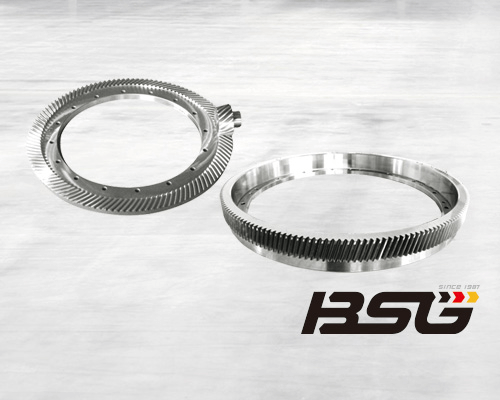

Large Precision Gear

Categories : Precision Gears

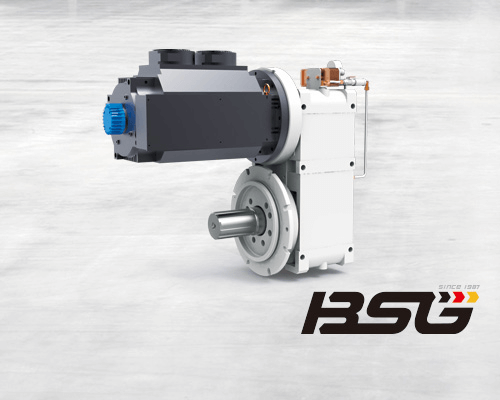

Direct Drive Gearbox

Categories : Gears

Precision Gears

Categories : Precision Gears

The world’s latest gear grinding instrument. Diversified precision gear profile modification technology ensures the best gear precision.

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALL...

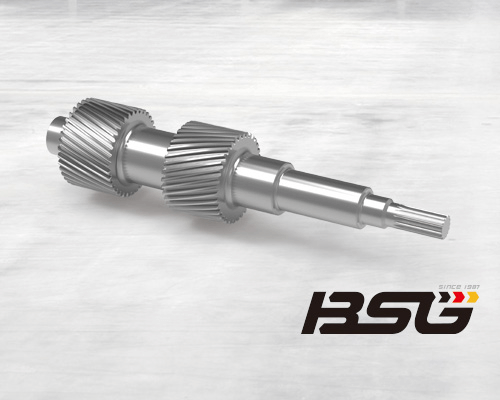

Cylinder Gear

Categories : Precision Gears

Counter Rotating Gearbox

Categories : Gears

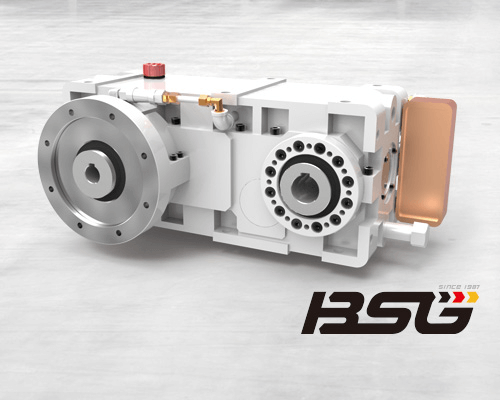

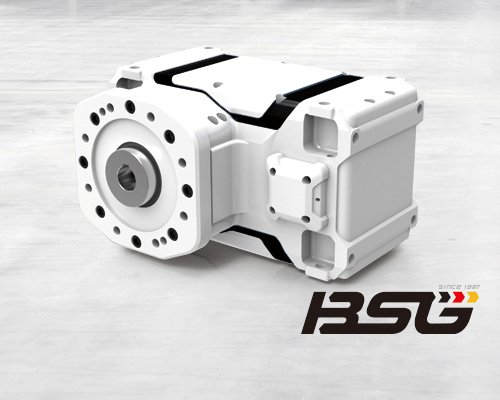

Right Angle Gearbox

Categories : Gears

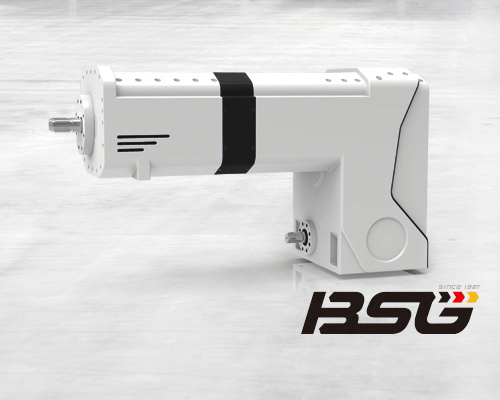

Single Screw Extruder Gearbox

Categories : Gears

Gearbox for Injection Machine

Categories : Gears

Gear Coupling

Categories : Gears

(1) Crowned tooth allowed larger tolerance in shafts and higher loads. (2) Special hardening treatment W/high strength and anti-abrasiveness. (3) Closed type coupling--easy lubricate & anti dust ...

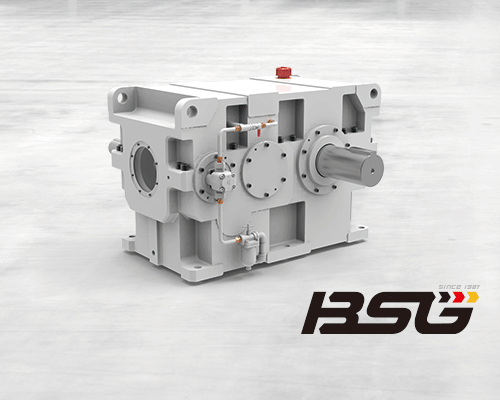

Parallel Shaft Gearbox

Categories : Gears

75 Liter Hollow Shaft Gearbox

Categories : Gears

Co-rotating Gearbox

Categories : Gears

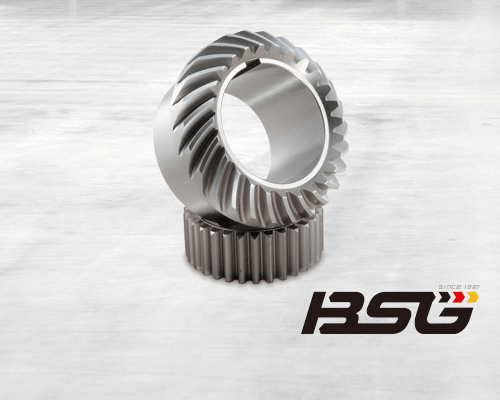

Spiral Bevel Gear

Categories : Precision Gears