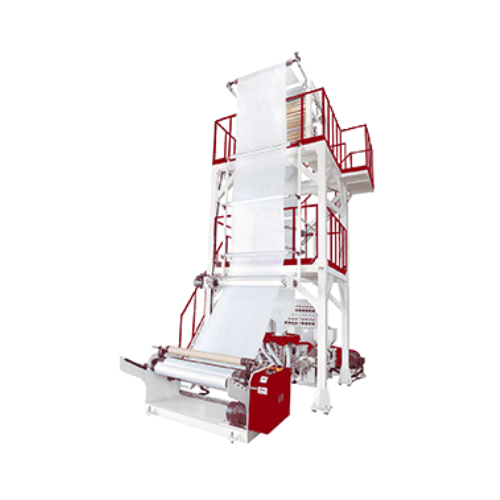

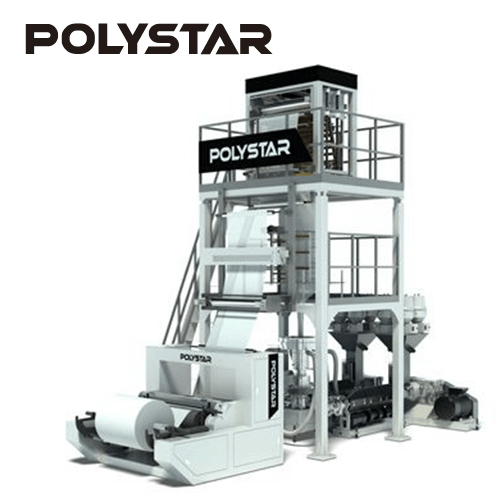

Three-Layer Co-Extrusion

Categories : Multilayer / ABA Blown Film Machine

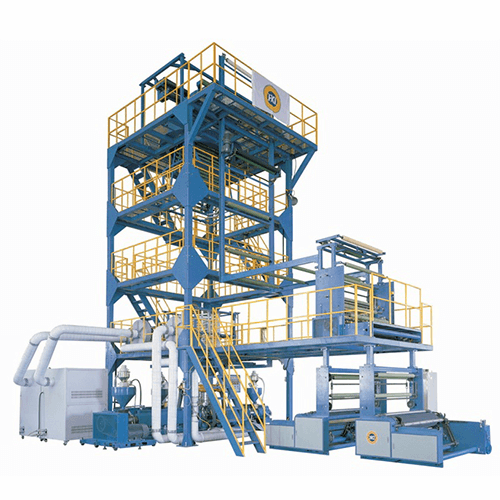

THREE-LAYER CO-EXTRUSION Blown Film Machine

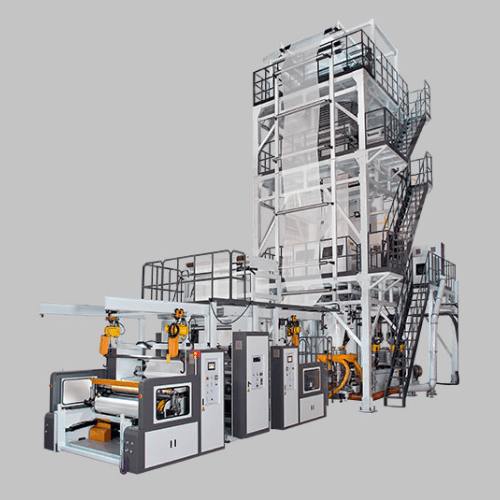

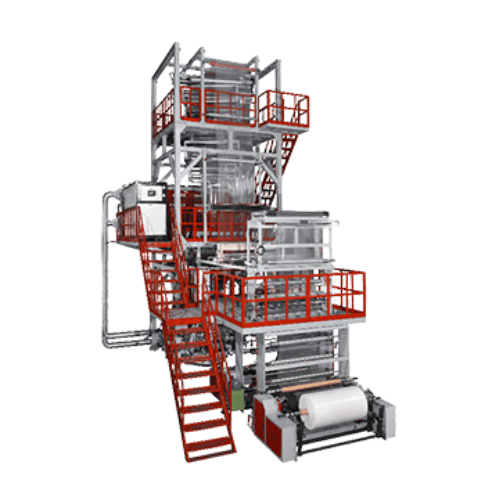

5-Layer Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Extruder 5-Layer PE Group/Recycled/PA/EVOH 5-Layer Co-Extrusion Blown Film Machine 5-LAYER CO-EXTRUSION BLOW

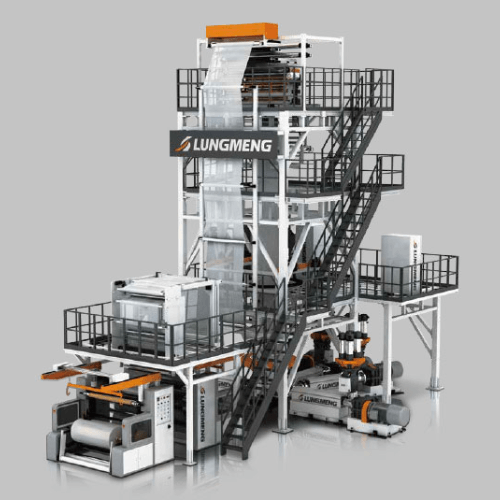

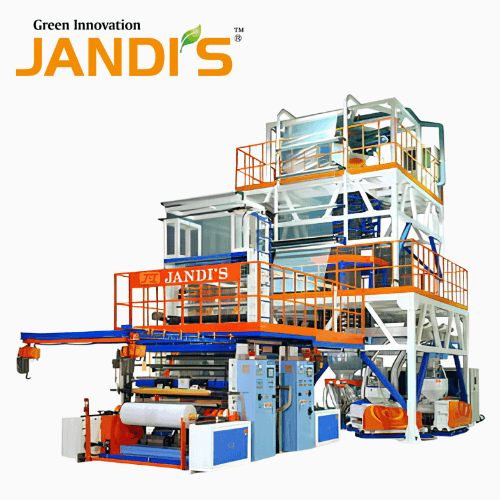

Five and Seven-Layer Co-Extrusion High Speed Blown Film Line

Categories : Multilayer / ABA Blown Film Machine

K.S. became a worldwide company; have achieved ISO 9002 certificate's requirements. K.S. machinery conforms to CE standard. Moreover, every machine must pass K.S. strict and careful quality con...

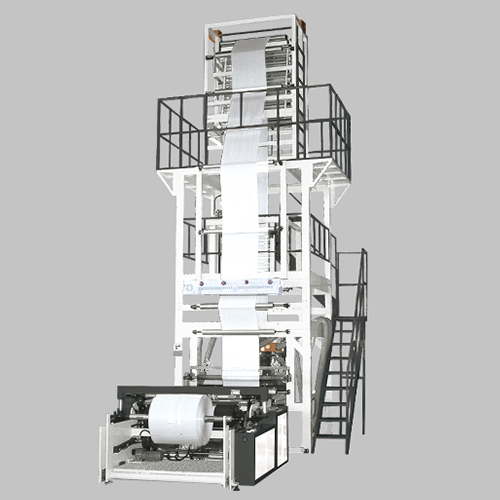

Two Layer AB blown film machine

Categories : Multilayer / ABA Blown Film Machine

For two color film production Extruder dia. 45mm, 55mm or 65mm

ABA Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Offering a wide range of Plastic Film Blowing Machines and its related components which are available to all the countries is what HSIN LONG keeps working on. For Three Layers ABA Co-Extrusion Blow...

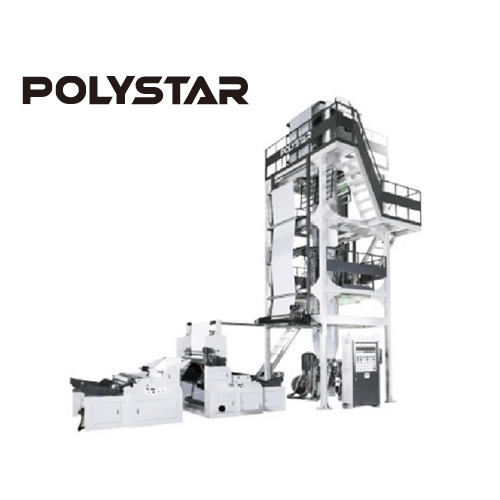

A/B/A BFT Series Co-Extrusion Blown Film Line- Oscillating Tower Type

Categories : Multilayer / ABA Blown Film Machine

Tubular lay flat width:From 40mm to 7 meter. -MONO LAYER, TWO LAYER, THREE LAYER & FIVE LAYER -SINGLE COLOR, DOUBLE COLOR, UP TO 4 COLOR.

LE-ABA Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

3-LAYER (ABA) PE GROUP_PP_RECYCLED

3-Layer Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Extruder 3-Layer (ABC) PE Group/PP/Recycled 3-Layer Co-Extrusion Blown Film Machine

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

Categories : Multilayer / ABA Blown Film Machine

3 Layer Co-Extrusion Inflation Machine (GF-L3C-MT)

A/B/A BFT Series Co-Extrusion Blown Film Line- Rotary Die Head

Categories : Multilayer / ABA Blown Film Machine

A/B/A BFT Series Co-Extrusion Blown Film Line- Rotary Die Head

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Multilayer / ABA Blown Film Machine

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EV...

3-Layer ABA Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

3-LAYER ABA CO-EXTRUSION BLOWN FILM MACHINE Extruder 3-Layer (ABC) PE Group/PP/Recycled

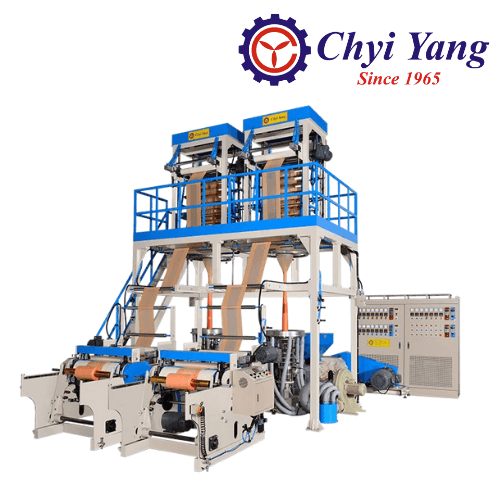

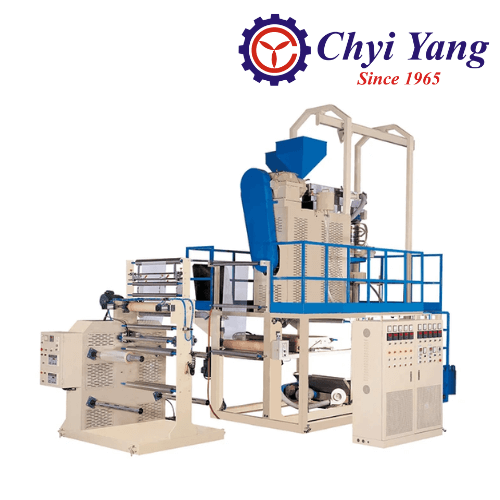

ABA 3-Layer Co-Extrusion

Categories : Multilayer / ABA Blown Film Machine

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die ...

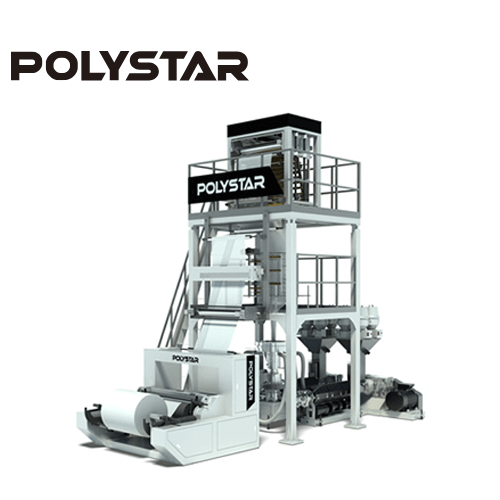

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

Categories : Multilayer / ABA Blown Film Machine

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-la...

LDPE Two Layer Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Kung Hsing LDPE Two Layer Co-Extrusion

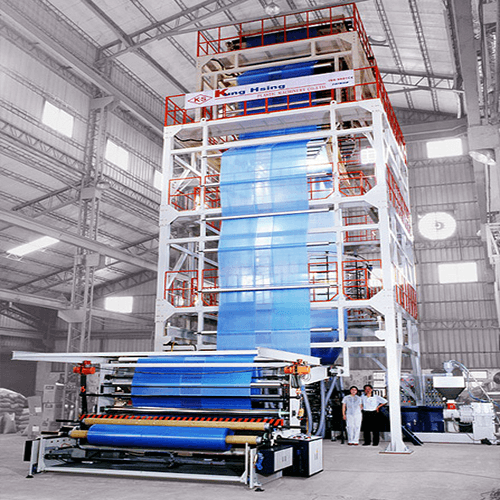

Three-Layer Co-Extrusion For Jumbo Bag (Industrial And Agricultural Use)

Categories : Multilayer / ABA Blown Film Machine

THREE LAYER CO – EXTRUSION LINE -- KS – CFLL100 + 120T WITH FLAT FILM WIDTH UP TO 5M, MAX. EXTRUSION OUTPUT 1.1 TONS

Three Layer ABA Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Film width up 500 to 1500mm(or more) 40mm or 45mm or 55mm or 65mm screw Industrial Packaging

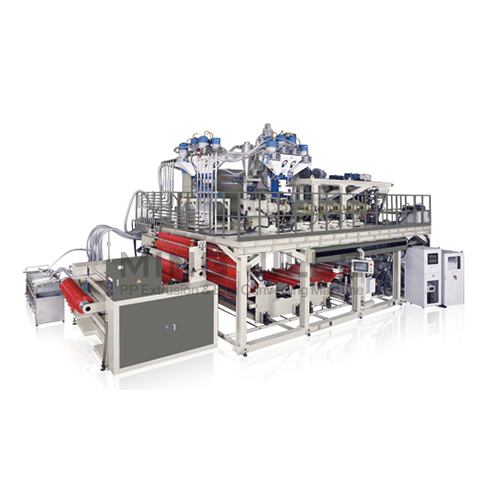

Triple Manifold CPP Film Co Extrusion Line

Categories : Multilayer / ABA Blown Film Machine

Triple Manifold CPP Film Co Extrusion Line

ABA Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

● ABA 3 Layer Co-extrusion ● Film Width from 500~1500mm ● Extruder Dia: 40mm,45mm, 55mm, 65mm ● Material: HDPE,LDPE, LLDPE,CaCO3, Additives ● Output: 45~150 kgs/hr

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably l...

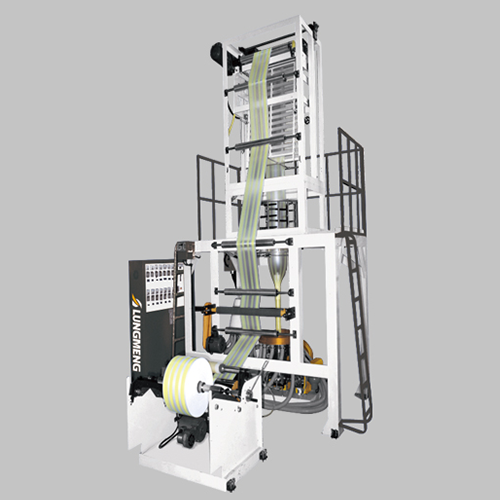

High Speed Two Color Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Extruder Mono-Layer HDPE/LDPE/mLDPE/PPHigh Speed Two Color Blown Film Machine This machine can produce two color striped plastic film and the color can be changed according to customer's requir...

Multi-Layers Co-Extrusion Blown Film Machine

Categories : Multilayer / ABA Blown Film Machine

Relying on the many years manufacturing experience of extrusion products, we understand the principle of each process of plastic blown film extrusion, we have the manufacturing capacity of blown fi...

A/B/C BFS Series Co-Extrusion Blown Film Line

Categories : Multilayer / ABA Blown Film Machine

FKI offers one of the most advanced and adaptable blown film lines for various applications, such as shopping bags, vest bags, garbage bags, agricultural film, construction film, packaging film and...