WASTE PLASTIC RECLAMATION & PELLET REGENERATING MACHINE (SPAGHETTI TYPE)

Categories : Plastic Pellet Making Machine

Available for dry and wet material, but you need to advise us in advance Simple operation & high capacity Application for PP, HDPE, LDPE, LLDPE, PS etc. Double extruder is used for bet...

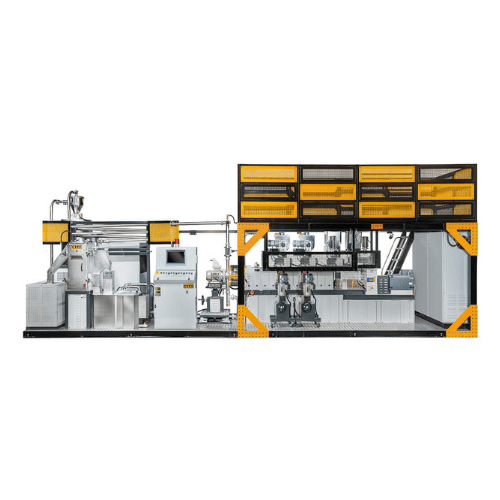

Automatic Strand Pelletizing System

Categories : Strand Pelletizer

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediatel...

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Strand Pelletizer

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such...

Automatic self-cleaning screen changer - RAS

Categories : WPC Pelletizing Machine

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve....

Pelletizing & Recycling System

Categories : Plastic Pellet Making Machine

MGB-RPW-65 For PP, HDPE and LLDPE recycling.

Water Cooling Pelletizer Line (Horizontal Type)

Categories : Water Cooling Pelletizing

WATER COOLING PELLETIZER LINE (HORIZONTAL TYPE)

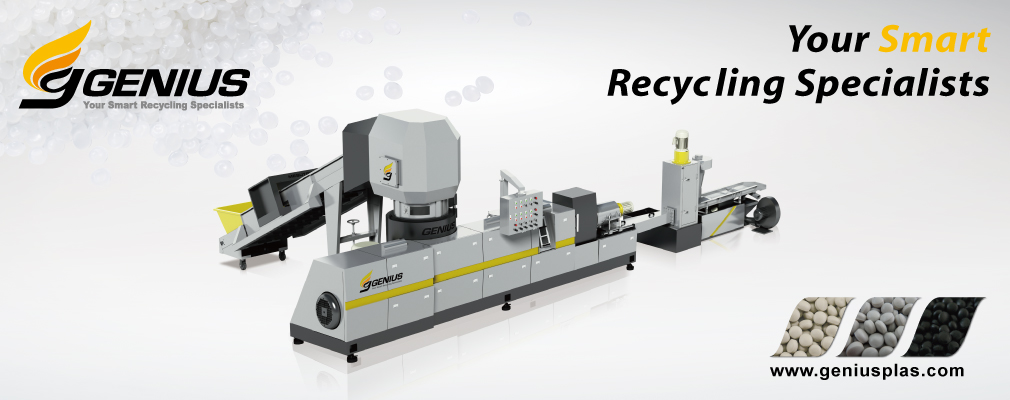

3IN1 Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pellet Making Machine

INTEGRATES SHREDDING, EXTRUDING AND PELLETIZING INTO ONE MACHINE Smash and mix well, heat, dry. High productivity, low noise. Easy operation and low labor cost. Two stages with venting holes for tr...

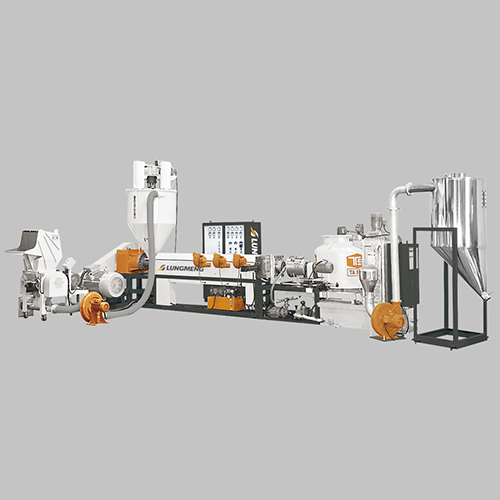

Side Force Feeder Type Recycling Pelletizing Extrusion Line | CK-SF

Categories : Plastic Pelletizer Machines

CK-SF series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE...

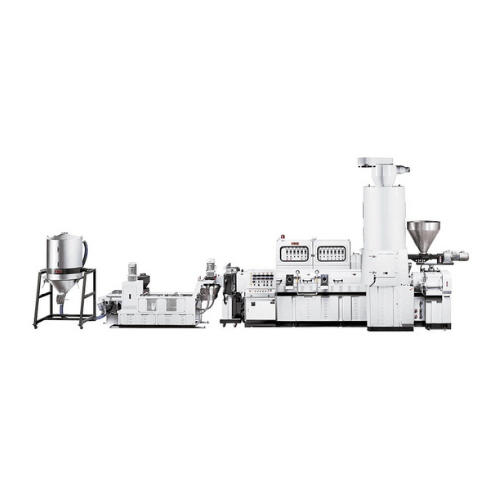

HF-TS SERIES: Plastic Pellet Extruder ( Twin Screw )

Categories : Plastic Pellet Making Machine

This pelletizing equipment (Twin screw pelletizing extrusion) is mainly applied to the thermal polymer compounding field, and we offer customized compounding solutions for any requests. We supply t...

Granulating System: Underwater Pelletizer

Categories : Plastic Pellet Making Machine

Underwater pelletizer with advanced water cooling technology. Energy saving, Easy Operation Underwater Pelletizing System. Mainly used for plastic materials such as PP、TPU、TPR、TPE etc.

Plastic Pelletizing Machine with Crusher

Categories : Plastic Pellet Making Machine

RECYCLING-PE-PP-ABS-PS

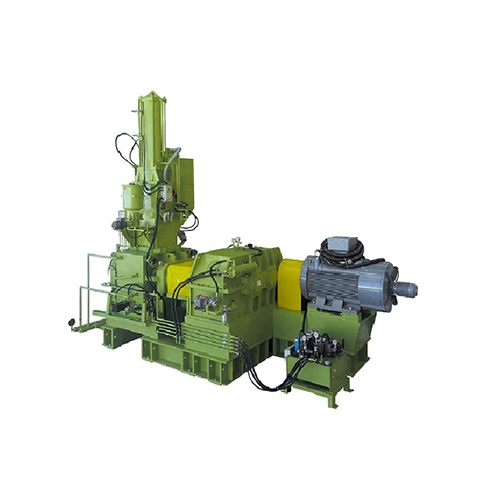

Intensive Mixer

Categories : Plastic Pellet Making Machine

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber:...

Pellets Cooling, Selecting, Collecting Unit

Categories : Water Cooling Pelletizing

This unit include Pellets Cooling, Selecting and Collecting after the pellets cutting from Extruder.

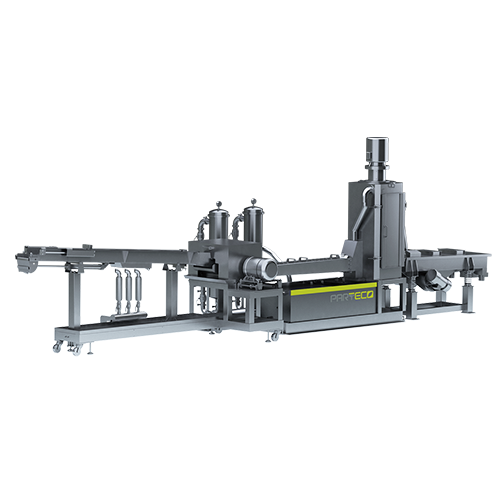

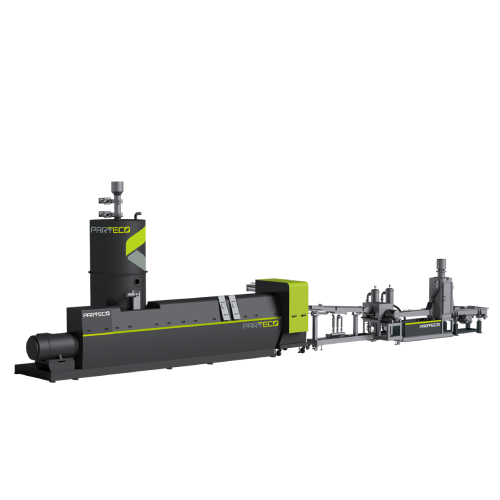

HF-FTO Vacuum Series: PET Extrusion Pelletizing Machine Line

Categories : Plastic Pellet Making Machine

In order to process PET, which is the most common plastic recycling material, PARTECO has developed this PET extrusion pelletizing machine line. The subject machine line (machine system) is mainly ...

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Pellet Making Machine

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Plastic Pellet Making Machine

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materi...

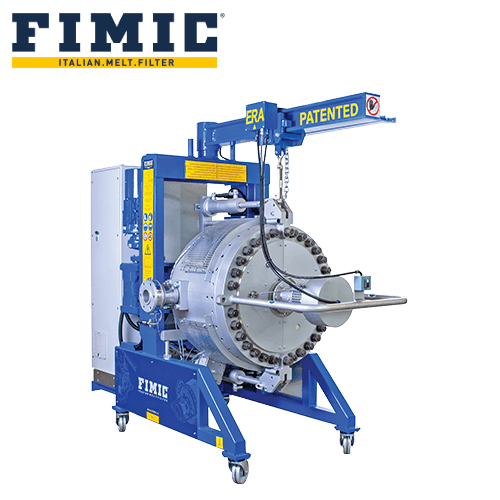

Automatic DOUBLE FILTER- ERA

Categories : Water Cooling Pelletizing

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machin...

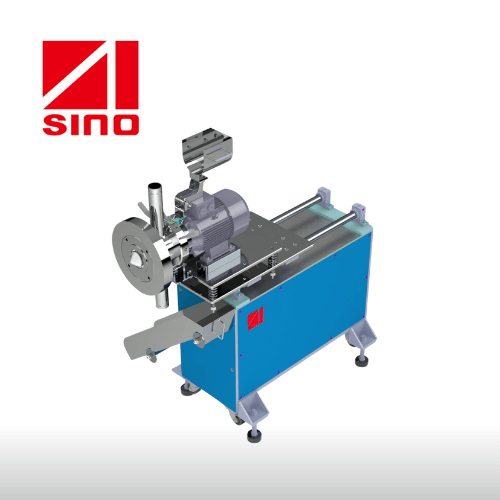

Underwater Pelletizer - PSQ

Categories : Plastic Pelletizer Machines

The PSQ underwater pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and sticky materials....

Laboratory Underwater Pelletizing Compounding System | CK-42HT

Categories : Plastic Pelletizer Machines

CK-42HT Laboratory Underwater Pelletizing Compounding System is designed for laboratory purpose, especially for experiments on the materials that have low melting temperature and high viscosity. ...

Twin-Cone High Speed Pelletizing Machine-Underwater Cutting

Categories : Plastic Pellet Making Machine

Suitable for high viscosity raw materials, such as PP, PMMA, TPU, PU, PLA, PET, TPU, PU, PLA and etc. High viscosity raw material. High Capacity, Low electricity usage, Easy to clean and chang...

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pellet Making Machine

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force fe...