Classification : Pelletizers

Country: Taiwan

Phone: 886-3-4838475

Fax: 886-3-4839052

Contact Person: Donald A. Stephens

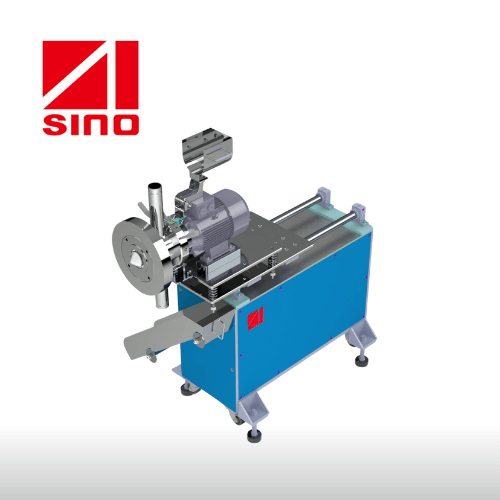

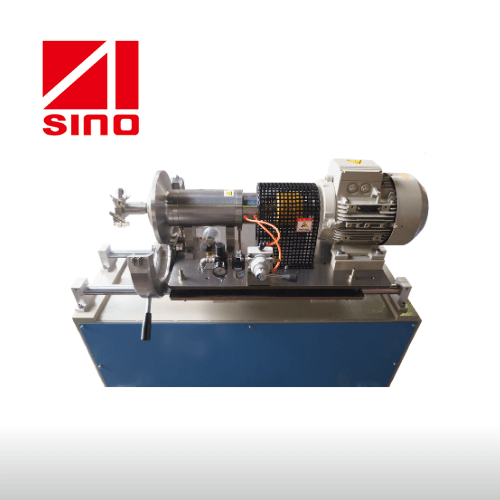

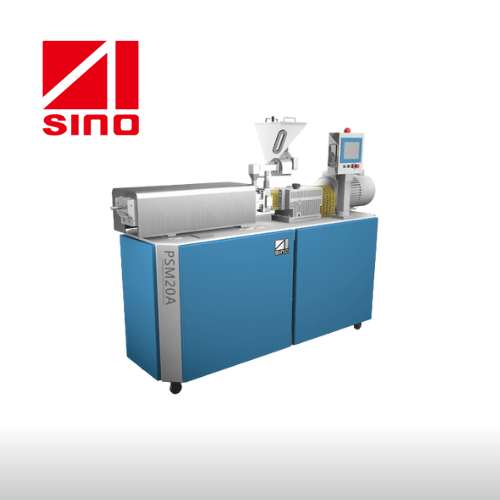

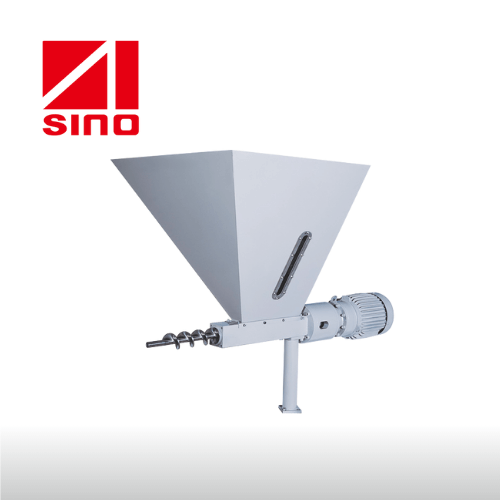

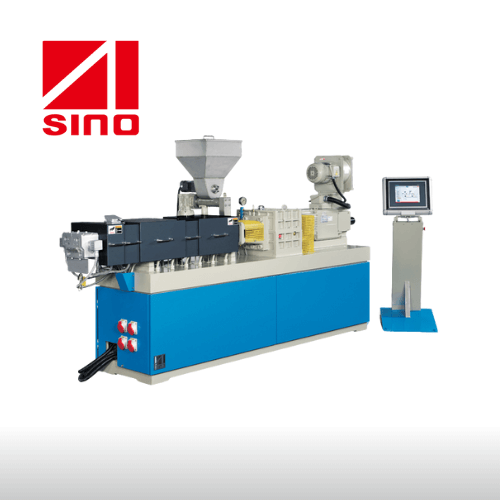

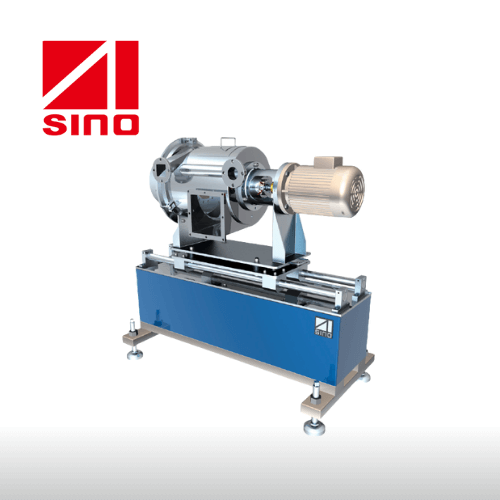

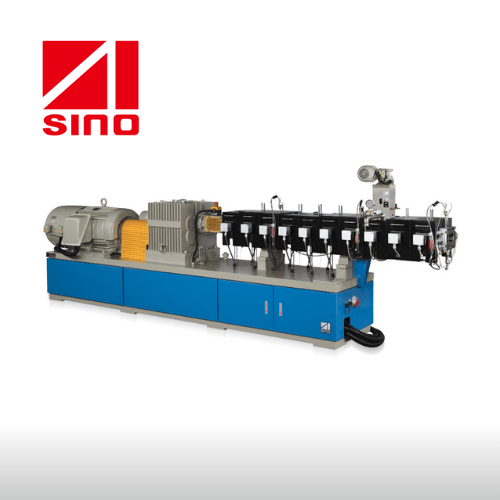

- The PSQ underwater pelletizer was developed by Sino-Alloy Machinery as an important accessory to our extruder line. Especially good at handling low hardness rubber material and sticky materials.

- Hot melt is extruded through a die into a water-filled cutting chamber where it is die-face cut by a high-speed cutter. The resulting spherical pellets are conveyed via water slurry to a centrifugal dryer.

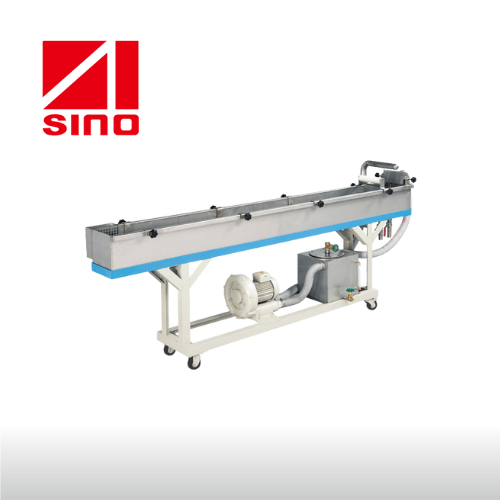

- Use in line with our PSL series centrifugal dryers to complete the underwater pelletizing system.

| Model | PSQ05 | PSQ20 | PSQ35 | PSQ45 |

|---|---|---|---|---|

| Throughput (kg/hr) | 15 | 50~300 | 110~700 | 300~1800 |

| Motor Power (kW) | 0.75 | 4.0 | 7.5 | 11 |

| Q'ty of Knives | 3 or 4 | 3 or 4 or 6 | 3 or 4 or 6 | 3 or 4 or 6 or 8 |

| Die (hole x dia.) | 2 x Ø2.5 | 10 x Ø3.3 | 40 x Ø3.3 | 80 x Ø2.8 |

| Heater Power (kW) | 6.52 | 10 | 18.3 | 18.3 |