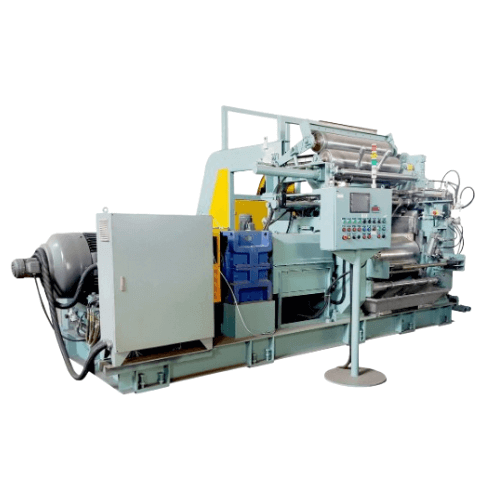

Mixing Mill / Sheeting Mill

Categories : Rubber Mixer

For Rubber、Plastic & Chemical Mixing/Sheeting This machine is suitable for mixing rubber, synthetic rubber, E.V.A. or PVC and various kind chemical material or sheeting for Extruder, Calender,...

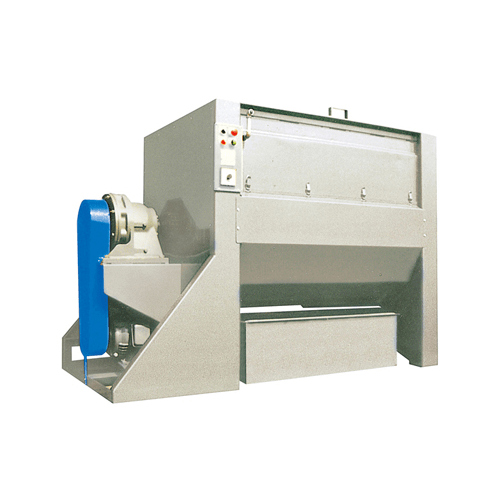

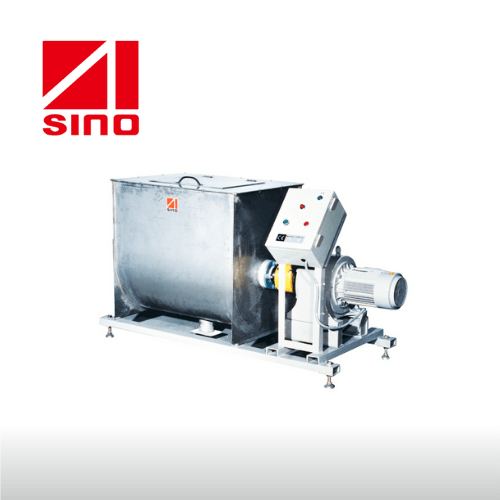

Plastic Mixer Machine

Categories : Rubber Mixers

The pug mill is a mixer for mixing the raw material for the plastic extrusion machine. Loading capacity from 300kg & 500kg.

Low-Speed Mixer-PSE

Categories : Rubber Mixers

The PSE low-speed mixer is a frequently used accessory for the PSM series co-rotating twin-screw extruder. Raw material does not heat up in the mixer which is beneficial to its stability. Af...

Laboratory dispersion kneader

Categories : Rubber Mixer

FEATURES: Mixer IT IS AN INDEAL EQUIPMENT FOR RESEARCH AND DEVELOPMENT OF THE LATEST RUBBER AND PLASTICS MATERIAL. IT IS SPECIALLY DESIGNED FOR COMPOUNDING WIDE RANGE AND SMALL BATCH OF RUB...

Mixing Mill / Sheeting Mill

Categories : Rubber Mixer

This machine is suitable for mixing rubber, synthetic rubber, E.V.A. or PVC and various kind chemical material or sheeting for Extruder, Calender, Hot Press or other processing machinery to make Ru...

Laboratory mix mill

Categories : Mixing Mill

The laboratory mill (mixing mill) is an essential piece of equipment in the rubber and plastic processing industries. It plays an important role in product quality control. The unit is ideal for ex...

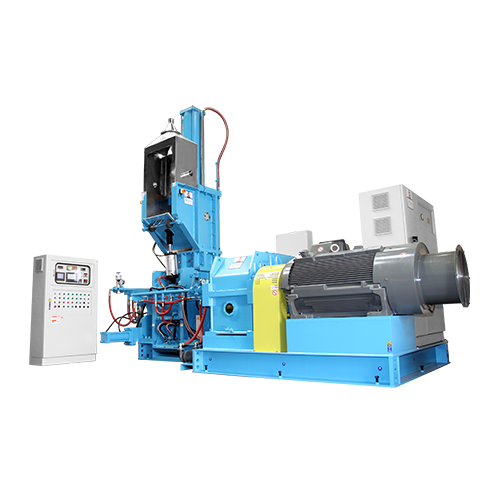

Rubber / Plastic Mixer Machine

Categories : Rubber Mixers

This Intensive Mixer is designed for mixing compounds and specific plastic. The structure of the machine consists of the main air cylinder, floating weight, feeding door, mixing chamber, rotors and...

Intensive Mixer

Categories : Rubber Mixer

Compounding For Rubber、Plastic & Chemical Industries Features: 1.Rotors: Two wings design with good cooling design. Excellent cooling ability. Anti-wearing treatment on the surface. 2.Chamber:...

Super Mixer

Categories : Rubber Mixer

Our company has designed & produced two model mixer- KCA: Adopts fixed rev. speed motor drive which suitable for general material mixing. KCB: Adopts pole change 2 steps speed motor drive which...

Round-Barrel Mixer CL-Z

Categories : Rubber Mixers

Suitable for many kinds of material. It is specially equipped with high speed motor & diffusion tool, which can mix material more evenly in a short time. No residual heat and no damage to the quali...

Vertical Mixer CL-MM

Categories : Rubber Mixers

Vertical Mixer Used for mixing dye, chemical raw materials, car brake material, for diffusing fiber glass, ferrite, cement with sand and dye, and for mixing stabilizer and metallurgic powder etc. ...

Rotational Mixer CL-RH

Categories : Rubber Mixers

Features 3 Layers Ribbon Mixing Blade Layers Ribbon Mixing Blade Low Power Low Speed No Heat Accumulation Big Volume Save Electricity Good Dispersion Minimal Abrasion

Vibration Bag Mixer Cl-FD50

Categories : Rubber Mixers

Industries Plastic raw materialsGlass fiberBrake raw materialsPowder metallurgyFertilizer Rubber industryChemical industryFood industryPowder CoatingsMasterbatch(PE,PP,PA,PVC,PS,ABS,TPE,EPS.etc.)...

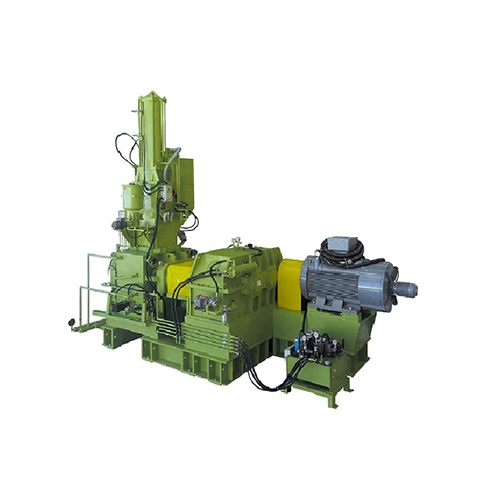

Air / Hydraulic - Dispersion Mixer (KNEADER)

Categories : Rubber Mixers

We Supply The Best Perfection Mixing Process:Rubber, Plastic, Compound, Composite, Electrical Material, Chemicals, Pigment, Food, Medical Erc…

Continuous Mixer with Extrusion Pelletizing Liner

Categories : Rubber Mixers

Mixing is needed to get the right consistency within masterbatch making machines. This Extrusion Pelletizing line has been constructed to focus on mixing different types of raw materials, so that t...

Two Roll Mixing Mill (Open Mill)

Categories : Rubber Mixers

The Two Roll Mixing Mill For Rubber、Plastic、PVC、EVA To Heating、Mixing And Chemicals Or Sulfur Material Uniformity It Can Be As Instead Of The Calender To Produce Un-Exact Rough Sheet Process.

Scraping High Viscosity Vacuum Mixer

Categories : Rubber Mixers

Application of high viscosity materials, make use of mixing, the use of forward and reverse stirring, so that a variety of materials in a stirred tank, can be mixed evenly. This machine is equip...

Air / Hydraulic - Intensive Mixer (BANBURY)

Categories : Rubber Mixers

Improve Compound Shearing Force And Superior Dispersion For Curing Process Low Temperature Mixing