Dosing and Measuring Equipment

Dosing and measuring equipment is essential in plastic processing, automation, and quality control. PRM-Taiwan features a wide range of reliable systems from trusted Taiwanese manufacturers, including Balance Scales, Batch Weighing Systems, Gravimetric Dosing Mixing Systems, Precision Weighing Equipment, Volumetric Dosers for Yarn, and Tensile Strength Testers.

These solutions are widely used in injection molding, extrusion, textile manufacturing, and laboratory testing, helping manufacturers achieve stable processes, consistent product quality, and reduced material waste. Explore high-performance dosing and measuring solutions on PRM-Taiwan today and upgrade your smart factory with precision and efficiency.

Tensile Strength Tester

Categories : Yarn Tensile Strength Tester

The GT-7010AEP is specially designed for measuring the strength of PP/HDPE flat yarn.

Large Quantity Auto Weight Scaling System

Categories : Batch Weighing System

Powder Weighing Unit is designed to transport various powder materials into the weighting tank according the pre-set value (recipe). The powders are transported by screw conveyer automatically. Eve...

Chemical Auto Weighting Device System

Categories : Batch Weighing System

1. High Precision 2. Less Pollution 3. Easy Clean 4. High Efficiency 5. More Data Storage

Batch-Off Machine

Categories : Batch Weighing System

Sheeting For Rubber Industries We will following customer inquiry to add stripping device、collecting device or metal detector, or other special device.

Dynisco 1480 – 1/8 DIN Panel Indicator

Categories : Dosing and Measuring Equipment

• Universal input (strain gauge, voltage, current, thermocouple or RTD) • Min/max value hold • 2 alarm outputs • Retransmission

Automatic Batch Weighing and Mixing System

Categories : Batch Weighing System

Automatically measuring equipment for efficient mix and material processing. Equip with auto conveying system, batching system, mixer, kneader, extruder and steel construction plant. Discharge feed...

Twin Screw Side Feeder-PSC

Categories : Dosing and Measuring Equipment

The PSC series twin-screw side feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line. Its design is based on Sino-Alloy’s years of experience. The...

Dynisco UPR900 – Process Indicator

Categories : Dosing and Measuring Equipment

Display pressure, temperature, or even differential pressure • Optional second input/output for cost-effective single instrument • Analog retransmission of process variable allows signal ...

Material Distribution Station

Categories : Volumetric Dosers

The function of material distribution station is to distribute materials to corresponding storage hoppers. There are five models of SMDS series, each equipped with quick couplers, so the loading an...

Gravimetric Master-Batch Feeder (MF-G)

Categories : Gravimetric Dosing Mixing System

The latest gravimetric master-batch feeder with lose-in-weight design (MF-G) increases your accuracy caused by the uneven size of master-batch or recycled resins. Customization is available to comb...

Electronic Analytical Balance Scale

Categories : Balance Scale

The DT analytical balances accurately measures the weight(denier) of PP/HDPE flat yarn.

Volumetric Dosers - SCM

Categories : Volumetric Dosers

SCM series volumetric doser is suitable for even feeding of masterbatch, additive, and virgin material to the plastic process machine. The unit has a selection of four dosing screw sizes for differ...

Gravimetric Auto Dosing & Mixing System (ADMG)

Categories : Gravimetric Dosing Mixing System

COST SAVE: ADMG can measure powder resin, granule resin, master-batch, or additive precisely. EASY OPERATE: By entering the percentage of each batch and supply value to operate effectively, HMI aut...

Gravimetric Blenders - SGB

Categories : Gravimetric Dosing Mixing System

• Evenly mixing of materials after accurately weighing, control accuracy strictly of ±0.1~±0.3%. • Auto calibration after each material weighting ensures accuracy. • ...

Dynisco 1496 & 1498 Temperature Controllers

Categories : Dosing and Measuring Equipment

• Easy to configure, simple to operate • Single device for heat control-only, heat/cool control, or indicator-only • Universal input • Selectable controller or indicator modes &...

Gravimetric Doser SGD

Categories : Gravimetric Dosing Mixing System

SGD gravimetric doser is suitable for continues precision dosing of masterbatch to the plastic process machine. The unit has a selection of four dosing screw sizes for different throughput needs. T...

Automatic Metering & Conveying System

Categories : Dosing and Measuring Equipment

In addition to storing barrel for Vacuum packages and storage function, this unit automatically handles powder package conveying, featuring easy operation, and avoiding the need to carry and add r...

Automatic Metering & Conveying System

Categories : Dosing and Measuring Equipment

Applications: PVC CORRUGATED SHEET

FVS Series Volumetric Screw Doser

Categories : Batch Weighing System

Signals from control cabinet are sent to motor, and then motor begins to work. The rotary force is transferred to the dosing screw through shaft connector. Color additives in hopper fall into the g...

Fully Automatic Mixing、Weighing & Conveying System

Categories : Dosing and Measuring Equipment

Fully Automatic Mixing、Weighing & Conveying System

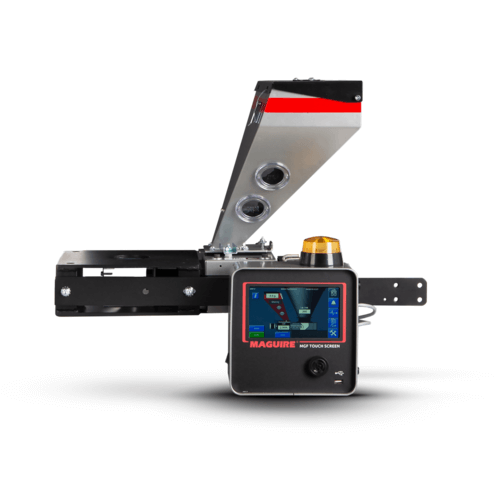

MGF Gravimetric Feeders

Categories : Batch Weighing System

Robust hardware, integrated with industry-leading software control to achieve repeatable consistent dosing accuracy. Unique twin load cell technology Dosing accuracy ± 0.2% on 1% set...