Classification : Feeders

Country: Taiwan

Phone: 886-3-4838475

Fax: 886-3-4839052

Contact Person: Donald A. Stephens

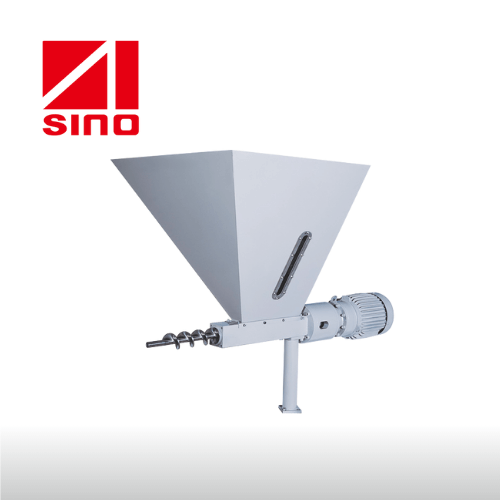

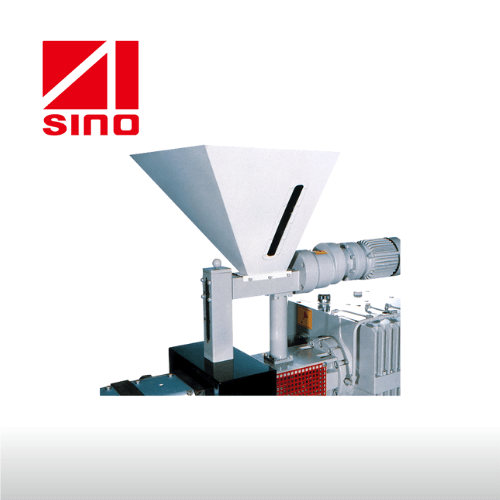

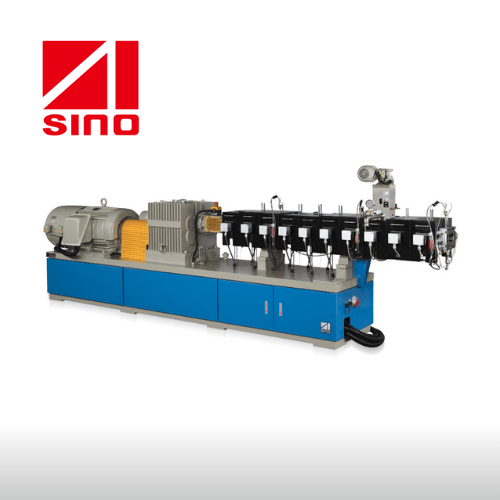

- The PSC series twin-screw side feeder was developed by Sino-Alloy Machinery as an important accessory to their extruder line.

- Its design is based on Sino-Alloy’s years of experience. The PSC twin-screw side feeder has a large feeding screw chamber for a smooth flow of the feeding material.

- The intermeshed type twin-screw has a self-cleaning feature with powerful displacement force, high feed volume, stable feeding, and excellent aeration properties, making it suitable for moist, low coefficient of friction powders and mixed types of plastics which require forced side feeding.

- Sino-Alloy Machinery can also tailor the design of a PSC twin-screw side feeder to match extruders from other manufacturers.

- Customers can also specify options such as preheating or cooling to suit production needs.

| Model | PSC18 | PSC25A | PSC40 | PSC70 | PSC92 |

|---|---|---|---|---|---|

| Throughput (kg/hr) | 2~15 | 5~30 | 20~120 | 80~500 | 160~1000 |

| Motor Power (kW) | 0.12 | 0.75 | 1.5 | 2.25 | 5.5 |

| Screw Speed (rpm) | 6~58 | 20~185 | 20~215 | 18~168 | 18~168 |

| Screw Diameter (mm) | Ø17.4 | Ø24 | Ø40 | Ø70 | Ø92 |