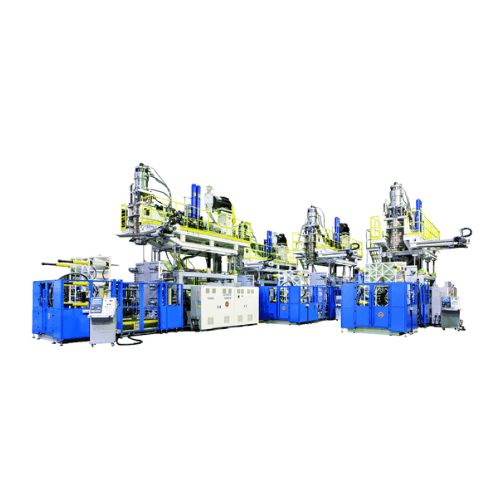

Extrusion Blow Molding Machines

Extrusion blow molding machines are used to produce hollow plastic parts by extruding a heated parison into a mold cavity. These machines are commonly used for making bottles, drums, tanks, and industrial containers in various sizes.

PRM-Taiwan provides extrusion blow molding solutions including Accumulator Head Blow Molding Machines and Continuous Extrusion Blow Molding Machines—offering excellent productivity and material versatility for automotive, packaging, and industrial sectors.

Accumulator Head Blow Moulding Machine for Water Pressure Tank

Categories : Accumulator Head Blow Molding Machines

Accumulator Head Blow Moulding Machine for Water Pressure Tank For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial blow moulding products.

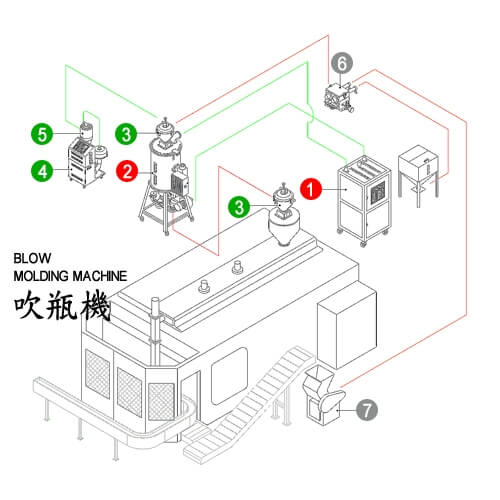

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Accumulator Head Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

Accumulator Head Blow Moulding Machines-40 Liter Float

Categories : Accumulator Head Blow Molding Machines

Accumulator Head Blow Molding Machines-40 Liter Float

3 Layer Co-Extrustion Bottom Blow Moulding Machine for 20lt~30lt jerry can

Categories : Extrusion Blow Molding Machines

3 Layer Co-Extrustion Bottom Blow Moulding Machine for 20lt~30lt jerry can Single Head, Double Station

Blow Molding Machine PBI-X Series

Categories : Accumulator Head Blow Molding Machines

This series of machine is equipped with a standard accumulator head. Especially ideal for producing picnic tables, tool boxes, toys, automotive duct, L-ring drums and stacking chemical drums up to ...

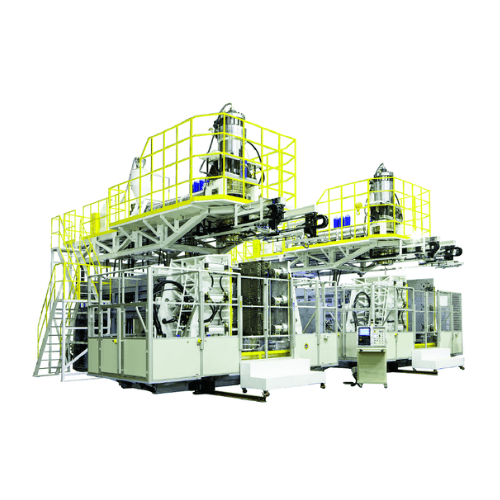

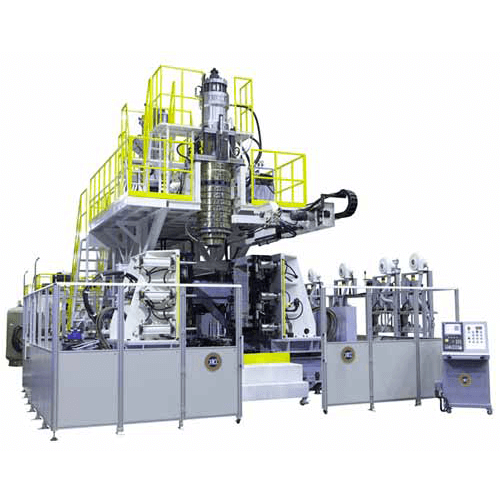

3 Layer, Co-Extrusion Blow Moulding Machine for L-ring Drum, with PWDS ABB Robot, 5 Set Post Cooling Units

Categories : Extrusion Blow Molding Machines

3 Layer, Continuous Extrusion Blow Moulding Machine (Fixed Type Clamping Press) 220lt Tight Head Drum

Accumulator Head Blow Moulding Machine for 4ft & 6ft Table Top

Categories : Accumulator Head Blow Molding Machines

Specially designed for making various sizes of table, chairs, with automatic cycle. Available table sizes from 30" till 96", also the round table, foldable at 60" diameter.

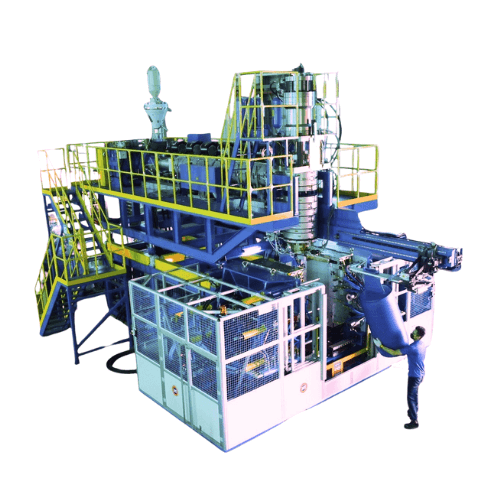

ABI Series,55 Gallon to 77 Gallon Open Head Drum Blow Moulding Machine High Efficiency , Cost Saving

Categories : Extrusion Blow Molding Machines

ABI Series,55 Gallon to 77 Gallon Open Head Drum Blow Moulding Machine High Efficiency , Cost Saving

Accumulator Double Head Blow Moulding Machines

Categories : Accumulator Head Blow Molding Machines

Accumulator Double Head Blow Molding Machines Mono Layer and Multi-layer Accumulator Head Type Blow Moulding Machine. For producing 20 liter to 1000 liter volume, all kinds of jerry can, contai...

Blow Moulding Machine For L Ring Drum, Air duct, table top and particular articles

Categories : Accumulator Head Blow Molding Machines

Blow Moulding Machine For L Ring Drum, Air duct, table top and particular articles

Accumulator Head Blow Moulding Machine for 400-600lt Fuel Tank

Categories : Accumulator Head Blow Molding Machines

Accumulator Head Blow Moulding Machine for 400-600lt Fuel Tank

Accumulator Head Blow Moulding Machines–Air Duct

Categories : Accumulator Head Blow Molding Machines

Mono Layer and Multi-layer Accumulator Head Type Blow Molding Machine. For producing 20 liter to 1000 liter volume, all kinds of jerry can, containers, air duct and industrial low molding products.

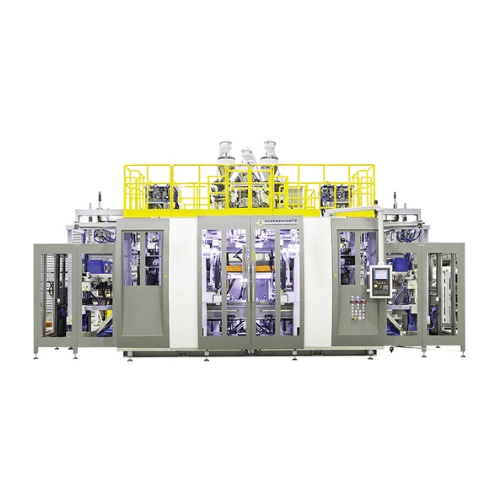

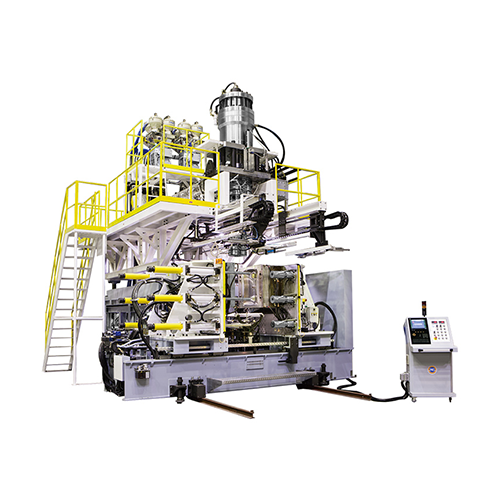

Accumulator Head Blow Moulding Machine for Table Top

Categories : Extrusion Blow Molding Machines

Compact design with less footprint Energy saving with high/low pressure circuit ONE HMI for total operation function Remote access for support diagnosis and troubleshooting Product...

Accumulator Head Blow Moulding Machines-L Ring Drum

Categories : Accumulator Head Blow Molding Machines

FKI offers the most practical Accumulator Head Blow Molding Machine for the industry with a wide range of applications: Cooking oil containers: from 10 to 30 liters Chemical use jerry cans: from 10...

Accumulator Head Blow Moulding Machine for L Ring Drum & Open Top Drum

Categories : Accumulator Head Blow Molding Machines

Accumulator Head Blow Moulding Machine for L Ring Drum & Open Top Drum

Accumulator Head Blow Moulding Machines-PC Drum

Categories : Accumulator Head Blow Molding Machines

Accumulator Head Blow Molding Machines-PC drum

Mono Layer Bottom Blow Moulding Machine for 20lt~30lt Jerry Can

Categories : Extrusion Blow Molding Machines

Mono Layer Bottom Blow Moulding Machine for 20lt~30lt jerry can Single Head, Single Station

Double Layer Accumulator Head Blow Moulding Machines

Categories : Accumulator Head Blow Molding Machines

Double Layer Accumulator Head Blow Molding Machines

Blow Molding Machine PBI SERIES

Categories : Accumulator Head Blow Molding Machines

Screw type with first-in and first-out accumulation type die head provide fast color change. 4 tie-bars for mold platens ensure uniform mold clamping.

All Electric Blow Moulding Machine for 800ml Bottle with view stripe

Categories : Extrusion Blow Molding Machines

All Electric Blow Moulding Machine for 800ml Bottle with view stripe

Semi-Automatic Pet Stretch Blow Molding Machine FS-1000HD2

Categories : Extrusion Blow Molding Machines

One Heating Machine One Stretching Machine. Small size and unoccupied space. It could produce 300c.c.~20Liter PET bottles and suitable for various bottles. Semi-auto PET Stretch Blow Molding Machin...

ES Series

Categories : Accumulator Head Blow Molding Machines

Basic accumulator type - Design for medium size products, something like toolbox, toy...etc .

Automatic Blow Molding machine With Pneumatic Clamping System- A Series

Categories : Extrusion Blow Molding Machines

This type is the pneumatic-clamping blow-molding machine, suitable for making popsicle (ice-lolly) & various small-size bottles. Extrusion is driven by the inverter motor with pulley-drive gear...

PET Stretch Blow Molding Machine-FS-4000AD

Categories : Extrusion Blow Molding Machines

Full Shine's PET Stretch Blow Molding Machine is an advanced machine for mass production.