Injection Molding Machines

Injection molding machines work by heating plastic materials until molten, then injecting them into a pre-designed mold under high pressure. After cooling and solidifying, the molded parts are ejected for mass production. This process is highly precise and repeatable, making it ideal for applications in packaging, electronic components, automotive parts, medical devices, home appliances, construction hardware, sporting goods, consumer products, and toys. It is a fundamental technology in modern plastic manufacturing.

PRM-Taiwan offers a comprehensive platform featuring a wide range of injection molding machines, including Hydraulic Clamping Injection Molding Machines, Electrical Injection Molding Machines, Toggle Clamping Injection Molding Machines, Vertical Injection Molding Machines, Horizontal Injection Molding Machines, Two-Platen Injection Molding Machines, High-Speed Injection Molding Machines, Micro Injection Molding Machines, Insert Molding Injection Molding Machines, Preform Injection Molding Machines, In Mold Labeling Injection Molding Machines, and Low Pressure Injection Molding Machines. Connect with leading Taiwanese manufacturers to streamline your supply chain and enhance your business efficiency.

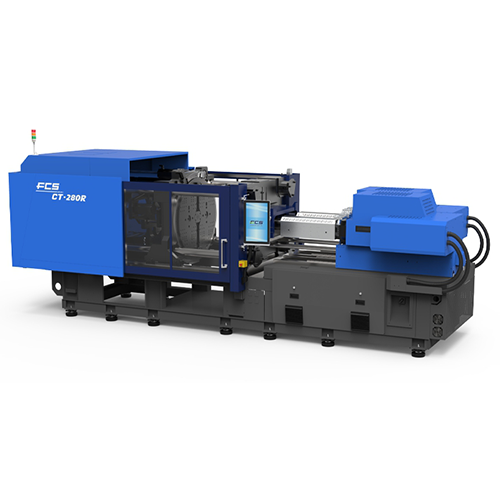

All-Electric Two-Component Injection Molding Machine (CT-R series)

Categories : Electrical Injection Molding Machines

It is All-Electric Two-Component injection molding equipment. It is suitable for two-component and multi-component products, including electronic parts, medical appliance, cosmetic containers, etc.

PET preform equipment (PET Series)

Categories : Horizontal Injection Molding Machines

It is PET preform equipment, which is suitable for mineral water, carbonated beverages, fruit juices, edible oils, medicine jars and lotions, cosmetic packaging containers, etc.

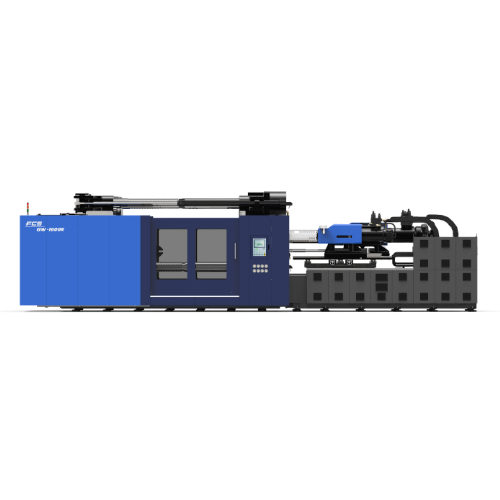

Two-Platen Multi-Component Injection Molding Machine (GW-R Series)

Categories : Injection Molding Machines by Platen

It is a newly launched large-scale two-plate multi-component injection molding machine, widely adopted in the automotive, home appliance, and furniture industries for manufacturing large two-color ...

BMC Injection Molding Machine (BMC Series)

Categories : Automatic Injection Molding Machine

It is BMC injection molding equipment, which is suitable for automotive parts, electronics industry, home appliances, housing and parts of communication equipment.

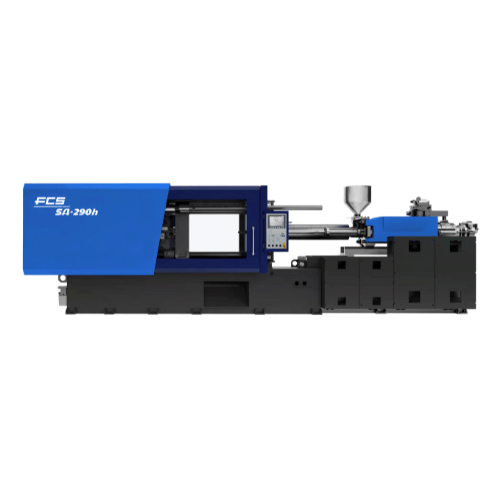

IMM for PET Blood Collection Tubes (SA-h PET Series)

Categories : Toggle Clamping Injection Molding Machines

It is a newly-released servo hydraulic energy-saving model with outward toggle clamping unit, which is specialized for PET tube. With clamping force ranging from 220 tons to 290 tons.

Special Purpose Machine KVV150/150 / Zipper

Categories : Vertical Injection Molding Machines

Experience efficient injection molding with our vertical injection molding machine. Vertical mold clamp, horizontal injection. Perfect for large work pieces.

Large Horizontal Rotary Table Two-Component Injection Molding Machine (HB-R Series)

Categories : Horizontal Injection Molding Machines

It is a large injection molding machine, which is suitable for large-scale home appliances and panels, automotive skylights, lights,

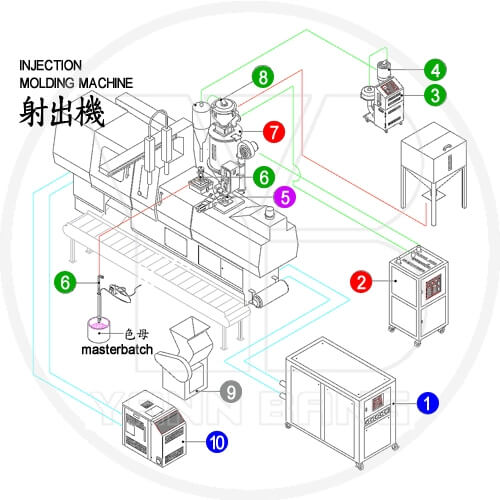

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperat...

PET Preform Series Injection Molding Machine - PET Series

Categories : Injection Molding Machines by Color

CHUAN LIH FA offers a full series of plastic injection molding machines for big, medium and small mouth PET preform production...

PET preform Injection Molding Machine (PET Series)

Categories : Horizontal Injection Molding Machines

It is PET preform injection molding equipment, which is suitable for mineral water, carbonated beverages, fruit juices, edible oils, medicine jars and lotions, cosmetic packaging containers, etc.

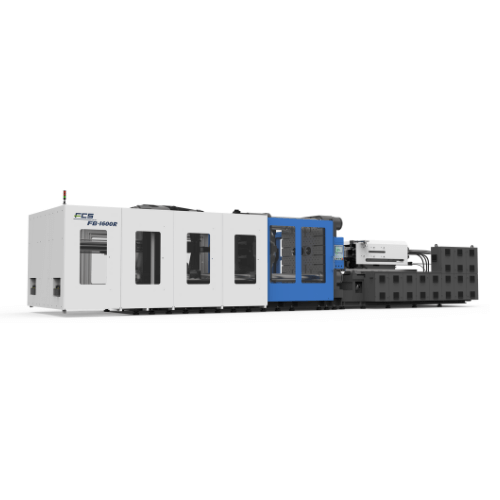

Large Rotary Table Two-Component Injection Molding Machine (FB-R Series)

Categories : Horizontal Injection Molding Machines

It is large rotary table two-component injection molding machine. It is suitable for two-component and multi-component products, including automotive light and home appliance… etc. With its ...

Two Platen Injection Molding Machine (LM Series)

Categories : Injection Molding Machines by Platen

It is medium and large scale injection molding machine. It is applicable to automotive industry such as bumper and

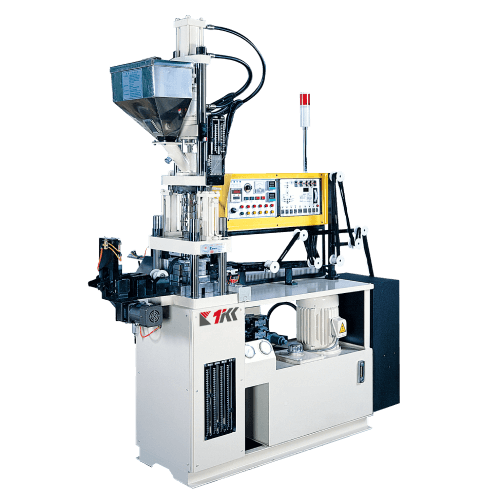

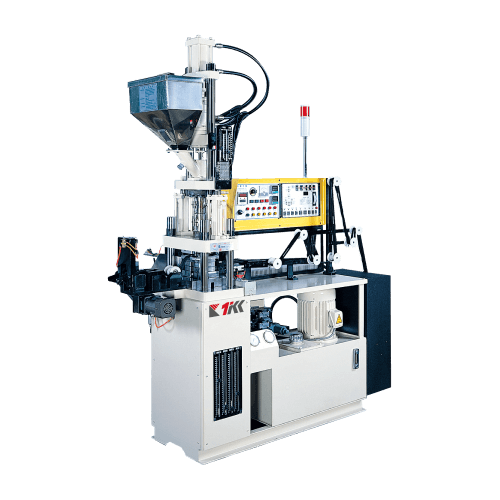

KR Series Plastic Injection Molding Machine (ROTARY TABLE)

Categories : Vertical Injection Molding Machines

Maximize productivity with our vertical injection machine. Vertical mold clamp, horizontal injection. Sturdy structure, user-friendly layout. Smooth movement, long lifespan. Customizable func...

Outward Toggle Type Plastic Injection Molding Machine - TWII-Series

Categories : Toggle Clamping Injection Molding Machines

Outward Toggle Clamping a Significant Increase in Structural Accuracy of Mold Platen Benefit: High Rigidity / Highly Precise Injection, Energy Saving / Customization Plasticized Applications: Prefo...

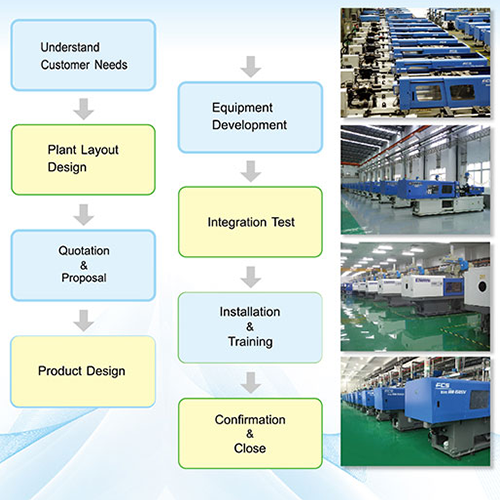

Turnkey Solution Service

Categories : Automatic Injection Molding Machine

Customers’satisfaction is always our main goal at FCS. We value customer’s satisfaction feedback as a guide to improve our service policies. Our service is available throughout the worl...

KET-100R All-Electric Injection Molding Machine

Categories : Vertical Injection Molding Machines

KETR Series (ROTARY TABLE)

Rotary Table Two-Component Injection Molding Machine (FB-R Series)

Categories : Horizontal Injection Molding Machines

It is rotary table two-component injection molding equipment. It is suitable for two-component and multi-component products, including automotive lamp housing, livelihood supplies, etc. FCS

KC Series Vertical Injection Molding Machine (ROTARY TABLE)

Categories : Vertical Injection Molding Machines

Vertical mold clamp and horizontal injection. No-post design is open on three sides and suitable for medium-size injected products with inclusions.....

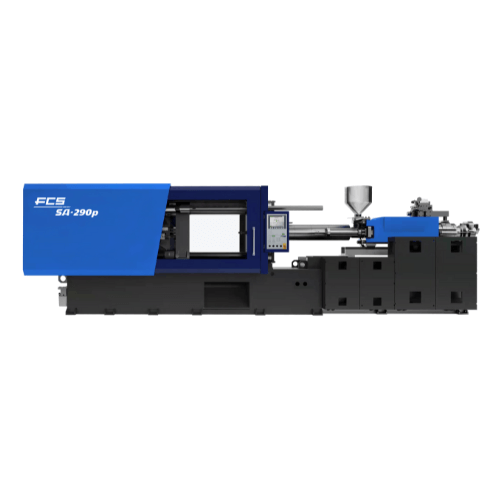

High-Speed Injection Molding Machine (SA-p Series)

Categories : Toggle Clamping Injection Molding Machines

It is a newly-released servo hydraulic energy-saving model with outward toggle clamping unit, especially suitable for producing bucket containers. With clamping force ranging from 220 tons to 1,000...

Plastic Injection Molding Machine - TX Series

Categories : Toggle Clamping Injection Molding Machines

A performance-proven plastic injection molding machine with a faster injection speed

PE Tube Heading Machine SIH-30-HC

Categories : Injection Molding Machines by Platen

With 250 sets memory storage in the computer and the monitor which can show the operating status.Insert tubes manually and remove tubes with air blowing unit.Double heading mould for fast running.M...

Special Purpose Machine KVV+VV-300/150 / Zipper

Categories : Vertical Injection Molding Machines

Our specialized vertical injection molding machine for zipper production offers exceptional performance. With its vertical mold clamp and horizontal injection, it ensures precise and efficient inje...

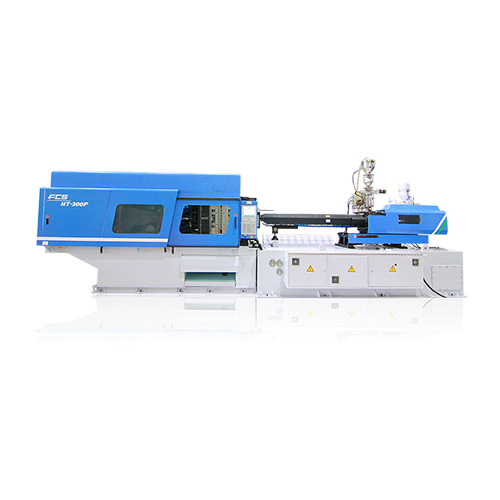

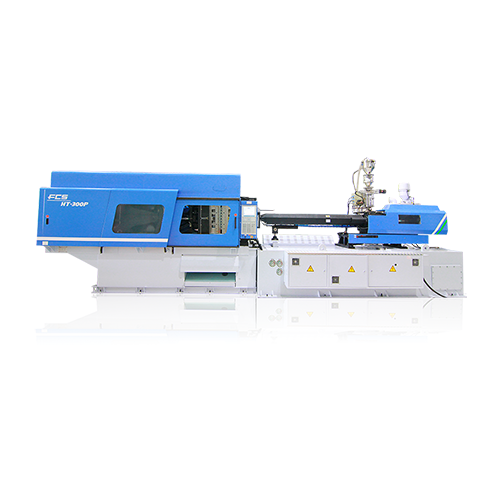

Servo Power-Saving Injection Molding Machine (HT Series)

Categories : Automatic Injection Molding Machine

It is standard and conventional equipment. The applicable industries include general household hardware products, electronic device housings, such as multifunction printer, laser printer or compute...

Advanced Servo Hydraulic Injection Molding Machine (FA Series)

Categories : Hydraulic Clamping Injection Molding Machines

Advanced Servo Hydraulic Injection Molding Machine (FA Series) It is a newly released model of advanced toggle hydraulic and servo energy-saving IMM by FCS. The applicable industries include housew...