Gearboxes

Gearboxes are essential transmission components that convert motor power into the required torque and speed. They are widely used in plastic extruders, injection molding machines, and rubber machinery to ensure stable power transfer, operational efficiency, and durability.

PRM-Taiwan offers a wide range of gearboxes tailored to various machinery: Extruder gearboxes are designed for single and twin-screw extrusion lines with enhanced torque and thermal stability; Injection molding gearboxes support high-pressure, rapid injection actions with precise gear engagement; Rubber machinery gearboxes are built for continuous processing of high-viscosity materials, emphasizing torque output and wear resistance; and specialized single-screw and twin-screw gearboxes meet specific process needs, enhancing machine stability and production capacity.

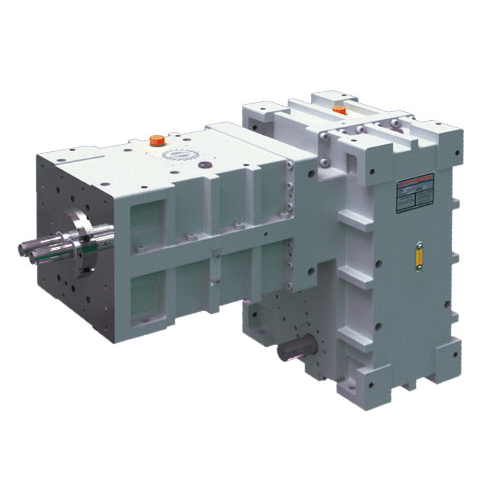

Gear Box for Parallel / Conical & Co-rotating / Counter-rotating Twin Screw Extruders

Categories : Twin Screw Extruder Gearboxes

Equipped with precise gearbox newly developed by ourselves,our extruder features improved performance, high efficiency, and extended service life. We also produce and export various kinds of extrud...

Screw, Barrel & Gear Box for All Kinds of Blown Film Machines / Extrusion Machines

Categories : Extruder Gearboxes

+For various extrusion machines. +To be made of SACM-645 steel through strict & precise process procedure with reliable quality.

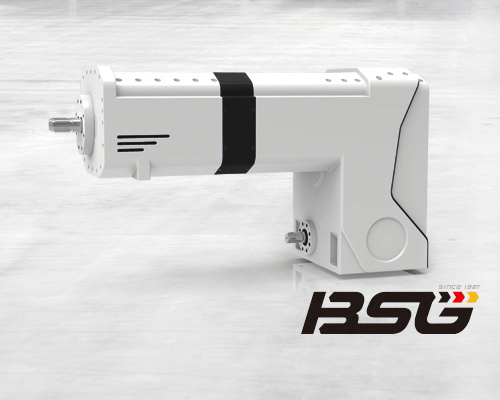

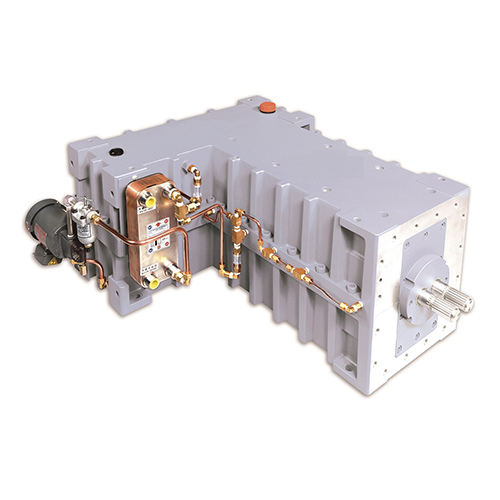

Stepless Gear Box with Selectable Input/Output Orientation

Categories : Extruder Gearboxes

Equipped with precise gearbox newly developed by ourselves,our extruder features improved performance, high efficiency, and extended service life. We also produce and export various kinds of extrud...

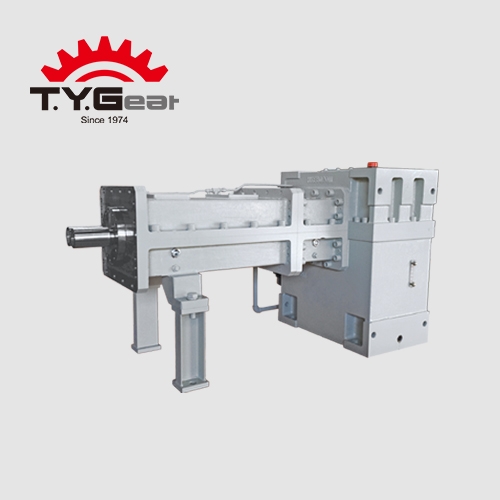

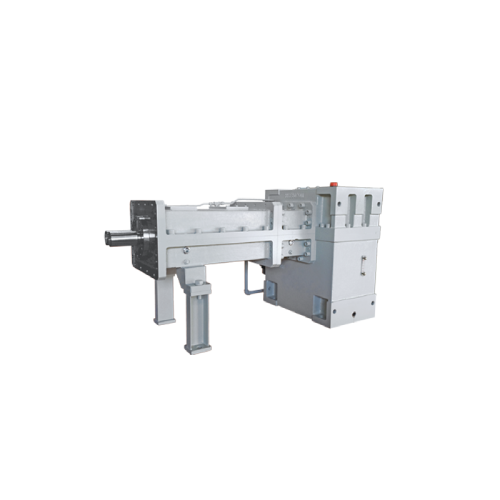

Screw, Barrel & Gear Box for Two-Stage / Multi-Stage Waste Recycling Machine (Side Feeding + Main Machine + Vice Machine)

Categories : Extruder Gearboxes

+For various waste materials recycling pelletizing. +To be made of SACM-645 steel through strict & precise process procedure with reliable quality.

for Extruder Machine - Single Screw Tex Series

Categories : Extruder Gearboxes

CASE Material: FC 25 module cast iron GEAR SHAFT a. Material : SNCM220.Carburization & Hardness HRc56∘~60∘ b. Gear precision: reach JIS 2 level GEAR ...

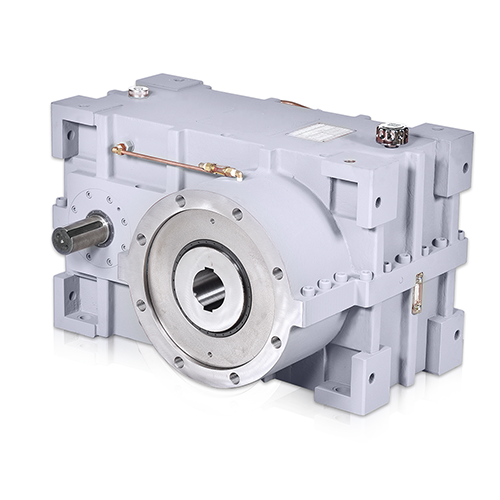

Gearbox for Single Screw Extruder

Categories : Extruder Gearboxes

we designed the best transmission efficiency, low noise, high torque gear box structure by using the computer virtual simulation and stress analysis calculation of safety coefficient.

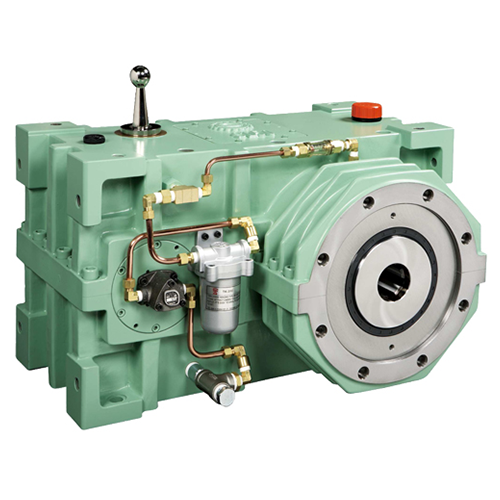

Twin Screw Extruder Co-Rotating Type

Categories : Twin Screw Extruder Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus...

for Electrical Injection Molding Machine- TGSM Series

Categories : Gearbox for Injection Molding Machine

Features: Save power & suitable for big tons of output in production High torque, High rotation speed, Less abrasion & low noise. Lubrication System: Oil Forced Type Rea...

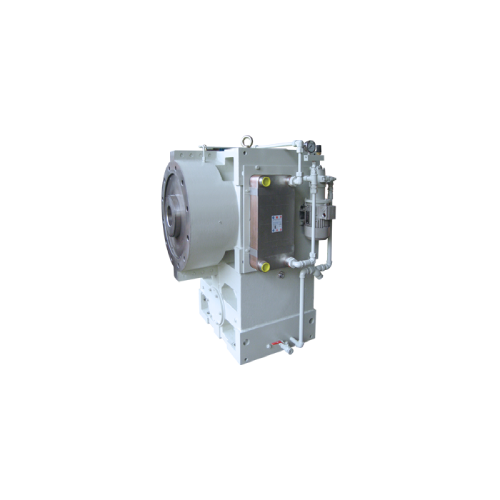

75 Liter Hollow Shaft Gearbox

Categories : Gearboxes

Precision Gears

Categories : Gearboxes

The world’s latest gear grinding instrument. Diversified precision gear profile modification technology ensures the best gear precision.

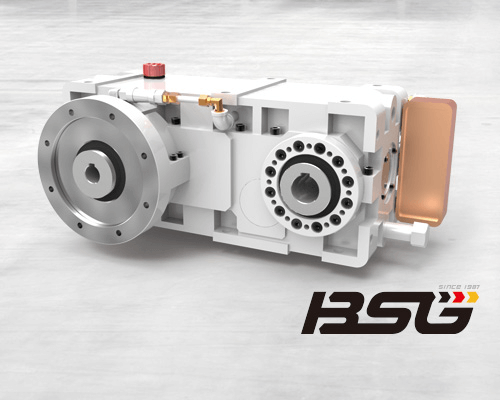

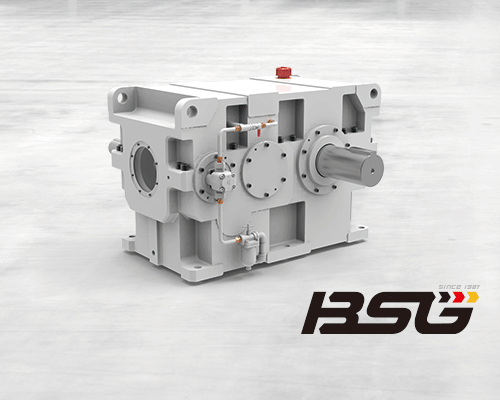

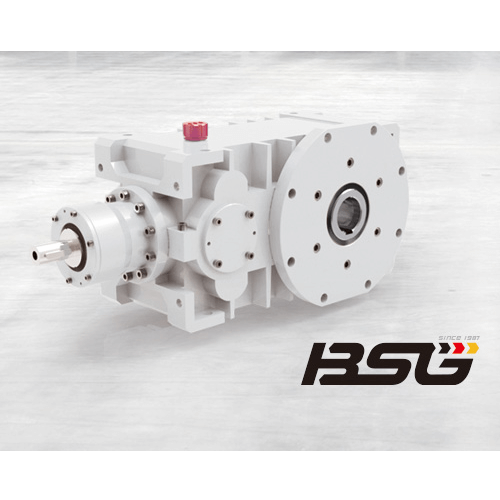

Parallel Shaft Gearbox

Categories : Gearboxes

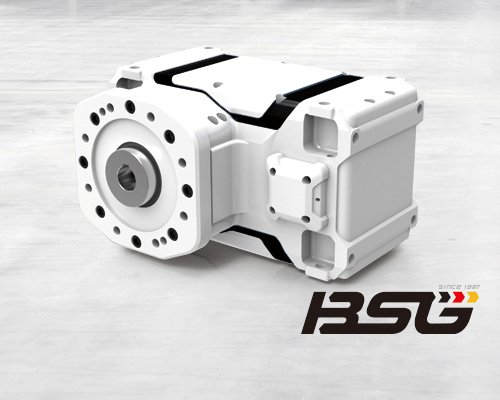

Right Angle Gearbox

Categories : Gearboxes

Twin Screw Extruder - Counter Rotating Type

Categories : Twin Screw Extruder Gearboxes

(1) Both Co Rotating & Counter Rotating types of TB series Twin Screw Gear Reducer are composed by Input & Output elements. Especially for output side which installed by Thrust Bearing plus...

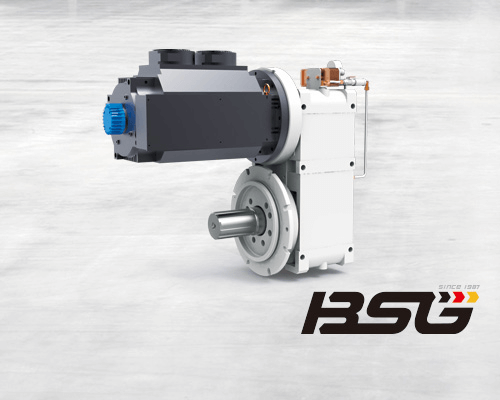

Gearbox for Electric Injection Molding Machine

Categories : Injection Molding Gearboxes

The gearboxes of injection molding machines have been developed properly for the drive of plasticizing screws.