Alu-Foil HSL Coating Machine (WAC Series)

Categories : Extrusion Coating Lamination Machine

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension contr...

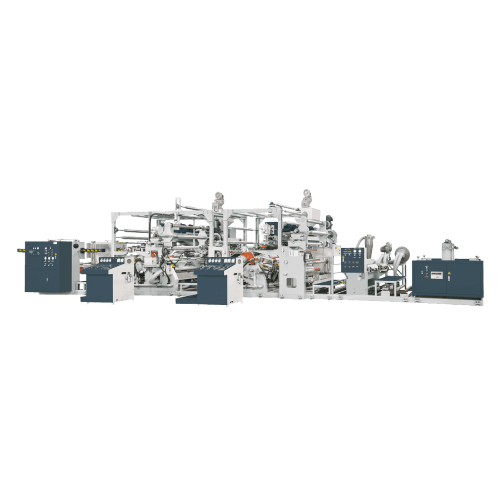

Feed Block Type Co-Extrusion Coating Machine (YSJ)

Categories : Extrusion Coating Lamination Machine

Our extrusion coating lamination machine is designed for high precision multi-layer laminated film to provide high quality flexible packaging material and other purpose materials.

Single Side Extrusion Lamination Machine (YSL)

Categories : Extrusion Coating Lamination Machine

This series of machines are available for jumbo bag, geotextile, spunbond and paper …etc. To do single side lamination process.

Tandem Extruder Machine (YSJ)

Categories : Extrusion Coating Lamination Machine

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

Mono Extrusion Coating Machine (YSJ)

Categories : Extrusion Coating Lamination Machine

Machine is equipped with an automatic control system so the operator can control it easily. The human machine interface panel displays operational status and information. Through the control panel,...

High Speed Mono Extrusion Coating & Laminating Machine (WEL-H Series)

Categories : Extrusion Coating Lamination Machine

In order to save the wastage of web path & minimized the film threading time. The machine adopt leading brands T-Die to ensure the stable performance & constant high quality coating gauge, ...

Tandem Extrusion Lamination Machine (YSL-T)

Categories : Extrusion Coating Lamination Machine

This series of machines are available for tubular woven bag, other working materials to do double side lamination process.

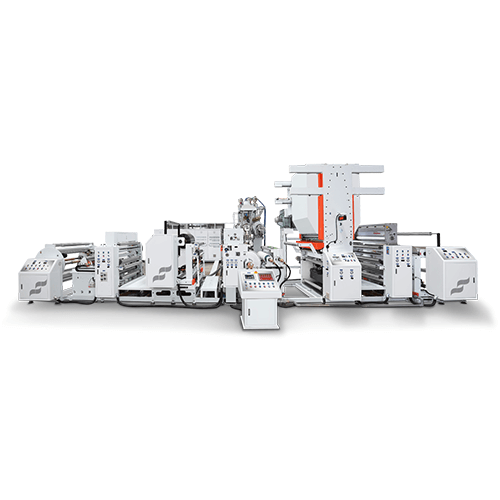

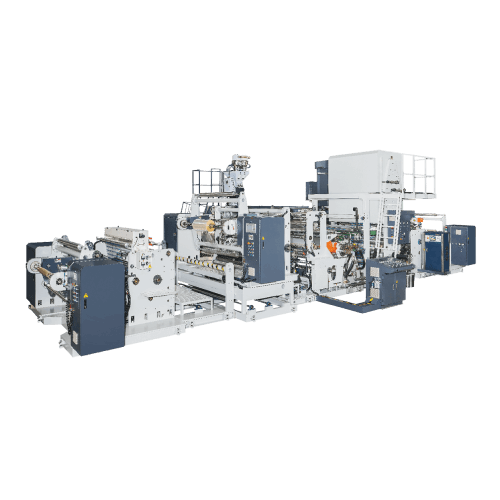

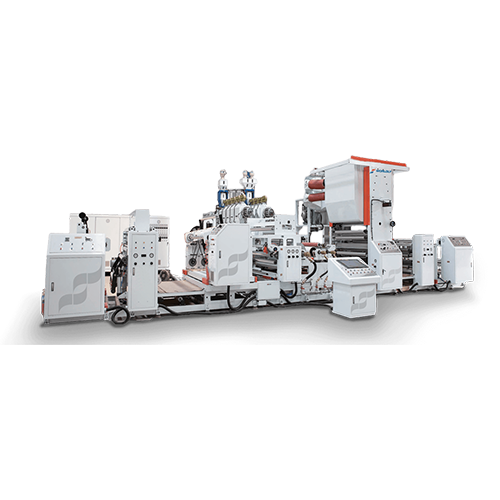

Extrusion Coating & Laminating Machine Tandem Type (WEL-DT Series)

Categories : Extrusion Coating Lamination Machine

The tandem type extrusion coating laminating machine has inline two extrusion units with three unwinders. It allows to produce five layers laminates in one go. It can save the semi-finished goods s...

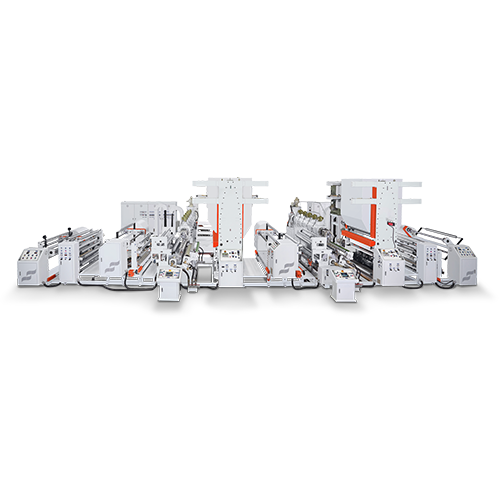

Co-extrusion Coating & Laminating Machine (WCL Series)

Categories : Extrusion Coating Lamination Machine

In this fast changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds resin or more by two or more extrusion units to create multi-...

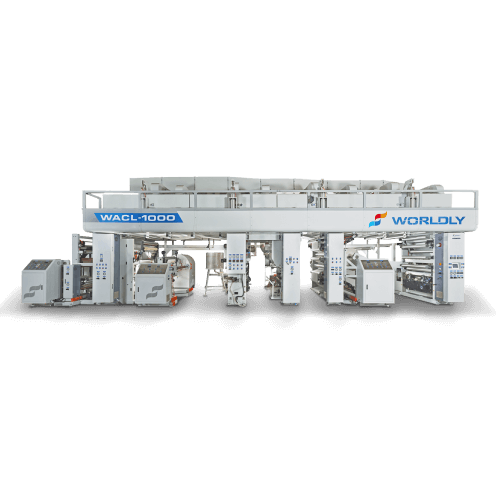

Aluminum Foil Coating & Laminating Machine (WACL Series)

Categories : Extrusion Coating Lamination Machine

WACL series is not just a convention dry laminating machine. The cold form foil is very much concerned proper & precise tension control to handle such thick laminates. In terms of tension contr...