5K+ Inquiries / year

100K+ Subscribers

900K+ Pageviews

PRM BUYER GUIDE

HOT PRODUCTS

SHOW ROOM

PRM-TAIWAN E-NEWS Subscribe Now

BLOG

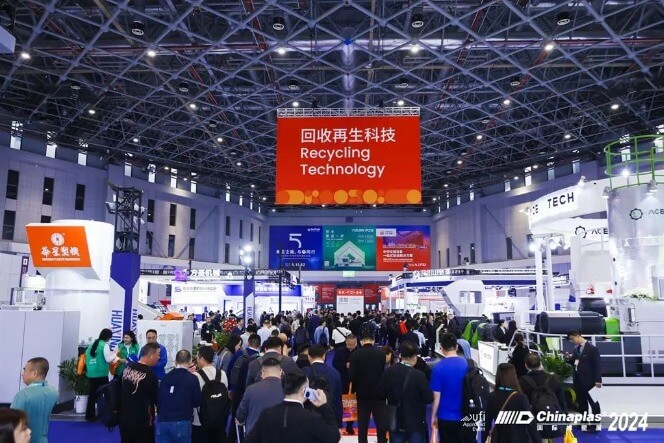

Show moreIt's Record Breaking! 211,928 Visitors for the First 2 Days!

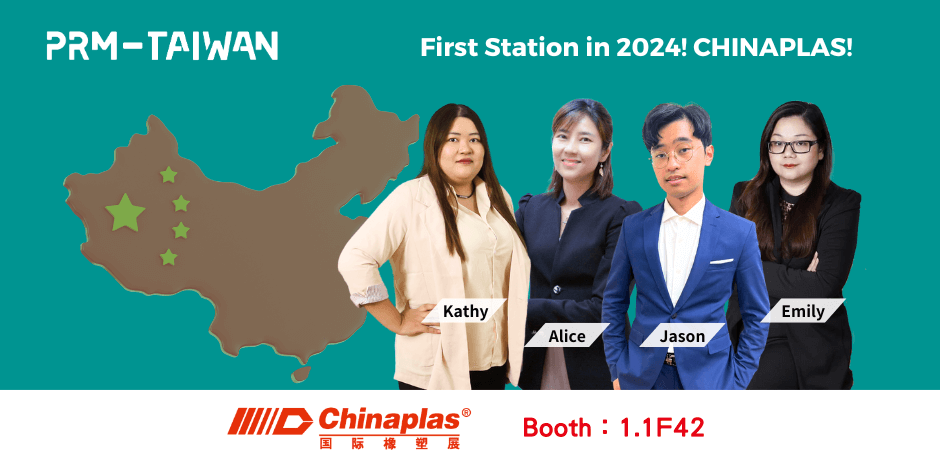

CHINAPLAS 2024 welcomed a record breaking of 211,928 visitors for the first 2 days. Among them, 44,242 came from overseas, comprising approximately 21% of the total visitors. Day 2 alone witnessed 118,687 visitors, marking a new height for single-day attendance. Of these, 24,862 were overseas visitors (~21%), establishing another new record for the daily overseas visitor no.

INDUSTRY INFORMATION

Show more19

Apr

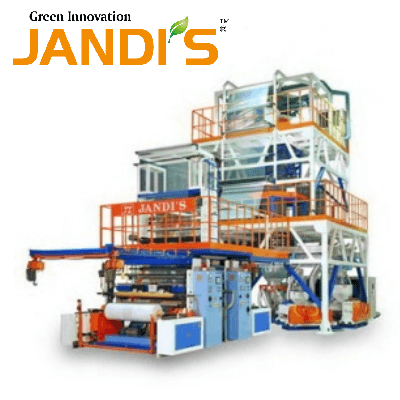

The extruder is the type of plastic and rubber machinery that values customization the most. It's not just about catering to customer needs through changes, but also proactively seeking innovations in line with changing times. This allows the machinery to perform at its highest efficiency, helping customers achieve optimized production while striving to reduce costs for maximum profitability.

12

Apr

(Heidelberg/Addis Ababa) Following the remarkable success of the 5th edition ofagrofood & plastprintpack Ethiopia of June 2023, the organisers are committed to raising the standards even further. Their relentless efforts are focused on enhancing every facet of the upcoming 6th edition.