Blow Molding Machine PBS 905PC SERIERS

Categories : Stretch Blow Molding Machine

The PBS-905PC Special Purpose Blow Molding Machine is specially designed with an advance German type die head, featuring "first-in, first-out" performance. It is ideal for producing high ...

5 Gallon Bottles PET Fully Electric Stretch Blow Molding Machine

Categories : Stretch Blow Molding Machine

CMSQ1 PET all electric stretch blow molding machines are suited for 3 gallon to 5 gallon water bottles.

PET Stretch Blow Molding Machine for Wide Mouth / Large Containers

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideal...

PET Automatic Stretch Blow Molding Machine for Hot Filling Bottles

Categories : Stretch Blow Molding Machine

The CMA (H) series stretch blow molding machines produce hot filling bottles for products such as fruit juices, isotonic drinks and RTD tea. These machines have a unique design according to the eff...

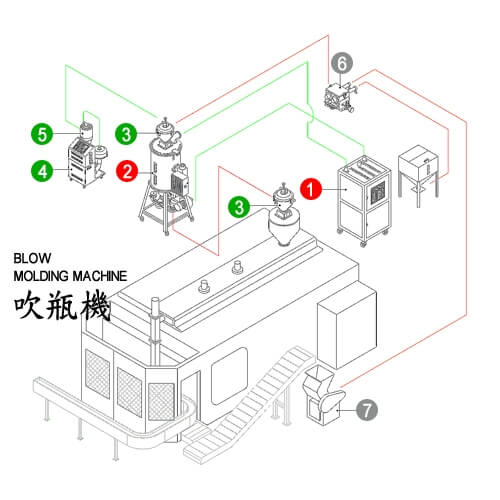

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Stretch Blow Molding Machine

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers,...

PET Stretch Blow Molding Machine for up to 1500ml Bottles

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and fo...

PET Stretch Blow Molding Machine for up to 600ml Bottles

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET bottles with volumes up to approximately 200 ~ 1500ml. Ideally suitable for large scale factories and fo...

Large Volume PET Blow Molding Machine-W/L Series

Categories : Stretch Blow Molding Machine

Large Volume PET Blow Molding Machine-W/L Series Robust hydraulic clamping.Double robotic arms for speedy preform loading.Cost Effective machine that is also easy to maintain.Compact structu...

PET Automatic Stretch Blow Molding Machine for Small Mouth Jar/Container

Categories : Stretch Blow Molding Machine

This is a new generation of fully automatic and versatile machine for mass production of PET large volume bottles, oval bottles, flat bottles and jars with volumes up to approximately 6000ml. Ideal...

PP Stretch Blow Molding Machine

Categories : Stretch Blow Molding Machine

This PP bottle blow machine is dedicated to the production of pharmaceutical packaging and high temperature hot filling heat resistant bottles. Today the chemical resistance and suitability for ste...

PET Stretch Blow Molding Machine - TEM06S2

Categories : Stretch Blow Molding Machine

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conve...

PET Stretch Blow Molding Machine - The World's Most Energy Efficient Bottle Production Line (EM Standard Series)

Categories : Stretch Blow Molding Machine

Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor...

PET Sretch Blow Molding Machine - Small Capacity of Diversity Bottle Production Line (LM Series)

Categories : Stretch Blow Molding Machine

Automatic PET stretch blow molding machine LM series match with high-speed precision blowing valve, air recovery converting to pressure operation will reduce air consumption. Preform from hopper tr...

PET Stretch Blow Molding Machine -TEM16S2

Categories : Stretch Blow Molding Machine

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single ...

PET Stretch Blow Molding Machine - Preferential Heating For Flat Containers (EX Series)

Categories : Stretch Blow Molding Machine

PET STRETCH BLOW MOLDING MACHINE - PREFERENTIAL HEATING FOR FLAT CONTAINERS (EX SERIES)

PET Stretch Blow Molding Machine - TEM04M1

Categories : Stretch Blow Molding Machine

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conve...

PET Sretch Blow Molding Machine - TEM04S2-88

Categories : Stretch Blow Molding Machine

PET STRETCH BLOW MOLDING MACHINE-TEM04S2-88 FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to...

PET Stretch Blow Molding Machine - TEM08M3

Categories : Stretch Blow Molding Machine

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conve...

PET Stretch Blow Molding Machine-FS-4000AD

Categories : Stretch Blow Molding Machine

Full Shine's PET Stretch Blow Molding Machine is an advanced machine for mass production.

PET Stretch Blow Molding Machine - TEM06M1

Categories : Stretch Blow Molding Machine

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conve...

PET Stretch Blow Molding Machine - TEM12S2

Categories : Stretch Blow Molding Machine

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single ...

PET Stretch Blow Molding Machine - Economy Affordable New Choice (EX Series)

Categories : Stretch Blow Molding Machine

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fa...

PET Stretch Blow Molding Machine - EX02MC-SH

Categories : Stretch Blow Molding Machine

● Blower power consumption for 1000 bottles: 2Wh. ● Air Compressor power consumption for 1000 bottles: 6 kWh compact space. ● Screw driven controlled by servo motor providing fast and smooth motion...

PET Stretch Blow Molding Machine - TEM08S2

Categories : Stretch Blow Molding Machine

● Adopt the touch screen control system with 64K color and friendly PLC operation. ● Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor ...