Classification : Stretch Blow Molding

Country: Taiwan

Phone: 886-4-22332281

Fax: 886-4-22306247

Contact Person: Sales Department

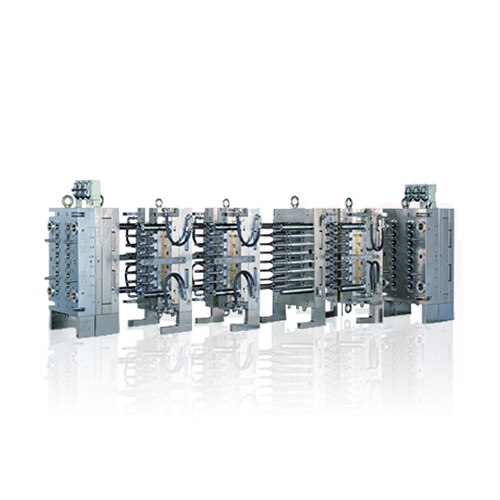

Preform Conveying System

Servo motor control makes delivery of preform to the mould very smooth and accurate.

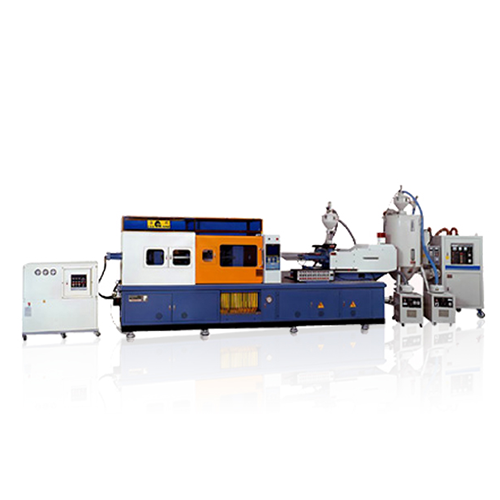

| Model | CMA-2000BD | ||

| Container | Max. neck diameter | mm | Ø28~Ø90 |

| Max. production capacity | pcs/hr | 1200 | |

| Max. body diameter | mm | 120 | |

| Max. container height | mm | 320 | |

| Max. bottle capacity | ml | 2000 | |

| No. of cavity | no. | 2 | |

| Mould | Carry pitch | mm | 152.4 |

| Mould center distance | mm | 152.4 | |

| No. of preform mandrels | pcs | 44 | |

| Heating oven | No. of even | no. | 3~4 |

| No. of infrared heaters in each oven | no. | 8 | |

| Heating load (max.) | kw | 38~52 | |

| Air pressure | Low pressure | kg/cm2 | 7 |

| High pressure | kg/cm2 | 35 | |

| Cooling water | Cooling capacity | kcal/h | 18000 |

| Water consumption | l/min | 80 | |

| Water temperature | °C | 10~12 | |

| Pressure | bar | 5 | |

| Total consumption power | kw | 42~56 | |

| Machine dimension | mm | 3.5x1.9x2.2 | |

| Machine weight | ton | 6.5 | |

* The production capacity refers to 500ml water bottles.

* CMA Series model can be upgraded to fully electricity type by servo motor control.