Classification : Extrusion Blow Molding

Country: Taiwan

Phone: 886-4-22332281

Fax: 886-4-22306247

Contact Person: Sales Department

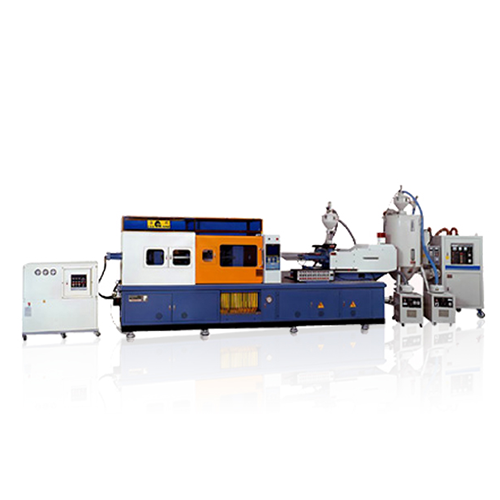

This series is a double station extrusion blow molding machine for containers from 50ml to 20L. These machines exhibit high reliability, excellent efficiency and flexibility to meet varied customer requirements.

- Screw design according to customer requirements. Screw and barrel are made of special steel and undergo nitrifying.

- The special structure of extruder and the vertical and longitudinal adjustment of the flat-table are adjusted automatically. Blow nozzle post is also auto adjust and equipped with a water cooling device.

- Specially designed hydraulics, circuiting, and accuracy of moulding movement & positioning.

- A parison parameter controller is also available for auto thickness adjusting.

- Auto bottom mould release and auto circular jar cutter are also available.

- Independent electrical cabinet, reduced vibration and computer control are according to customer request.

| Model | CM-45SH2D | CM-55SH2D | CM-65SH2D | CM-75SH2D | CN-90SH2D | CM-45DH2D | CM-55DH2D | CM-65DH2D | CM-75DH2D | CM-90DH2D | CM-55FH2D | CM-65FH2D | CM-75FH2D | CM-90FH2D | ||

| Model | Material to be Used | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | PE/PP | |

| Screw Diameter | mm | Ø45 | Ø55 | Ø65 | Ø75 | Ø90 | Ø45 | Ø55 | Ø65 | Ø75 | Ø90 | Ø55 | Ø65 | Ø75 | Ø90 | |

| L/D Ratio | 24/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 24/1 | 26/1 | 24/1 | 24/1 | 24/1 | 26/1 | ||

| Screw Speed Range (PE)/rpm | rpm | 15-85 | 20-80 | 20-80 | 20-75 | 20-65 | 15-85 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-60 | |

| Inverter Motor | HP | 15 | 20 | 25 | 40 | 50 | 15 | 20 | 20 | 50 | 60 | 20 | 25 | 50 | 60 | |

| Max. Extrusive Capacity/Hour | kgs | 25 | 37 | 50 | 78 | 105 | 25 | 37 | 44 | 78 | 105 | 37 | 60 | 78 | 105 | |

| Heating Zone (Barrel) | zone | 2 | 3 | 3 | 3 | 3 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Heating Capacity (Barrel) | kw | 3.9 | 7.2 | 10.8 | 14 | 25.2 | 3.9 | 7.2 | 10.8 | 14 | 25.2 | 7.2 | 10.8 | 14 | 25.2 | |

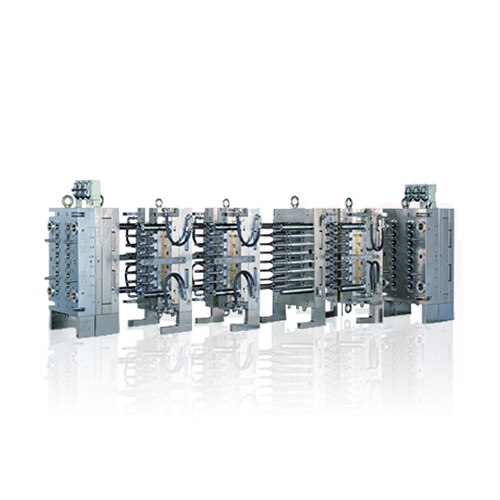

| Die head | Heating Zone (Diehead) | zone | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 5 | 5 | 5 | 5 | 9 | 9 |

| Heating Capacity (Diehead) | kw | 3.5 | 5.8 | 8 | 8.6 | 16.4 | 5.4 | 7.7 | 11.9 | 12.6 | 25.2 | 12 | 13 | 14.7 | 21.4 | |

| Double Mold Center Distance | mm | - | - | - | - | - | 120 | 130 | 140 | 160/180 | 200/220 | 85 | 100 | 100 | 120 | |

| Mold Plate | Max. Opening Stroke | mm | 350 | 410 | 550 | 610 | 635 | 399 | 410 | 550 | 610 | 635 | 410 | 550 | 610 | 570 |

| Min. Close Stroke | mm | 80 | 100 | 172 | 210 | 233 | 150 | 100 | 172 | 210 | 233 | 100 | 172 | 210 | 250 | |

| Mold Clamping Force | ton | 4 | 5.5 | 8 | 9 | 10.8 | 4 | 5.5 | 8 | 9 | 10.5 | 5.5 | 6 | 9 | 10.5 | |

| Hydraulic System | Hydraulic Pump Motor | HP | 15 | 15 | 20 | 20 | 30 | 15 | 15 | 20 | 20 | 30 | 15 | 20 | 20 | 30 |

| Hydraulic Oil Pressure | kg/cm2 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| Oil Tank Capacity | gallon | 50 | 75 | 100 | 100 | 125 | 50 | 75 | 100 | 100 | 125 | 100 | 150 | 180 | 200 | |

| Product | Product Weight (Max.) | g | 60 | 100 | 170 | 280 | 450 | 40 | 80 | 120 | 140 | 160 | 12 | 30 | 50 | 60 |

| Product Dia. (Min./Max.) | mm | 20-85 | 20-100 | 30-140 | 50-200 | 70-260 | 10-85 | 20-85 | 30-105 | 50-125 | 40-145 | 10-70 | 10-70 | 20-85 | 30-105 | |

| Product Capacity (Min./Max.) | ml | 100-500 | 250-1000 | 500-2500 | 1000-5000 | 4000-10000 | 10-200 | 100-500 | 300-1000 | 600-2000 | 1000-3000 | 50-150 | 100-300 | 300-500 | 500-1000 | |

| Total Power Consumption | kw | 33.5 | 42.8 | 56.1 | 71 | 106 | 35.4 | 44..7 | 56.3 | 82.6 | 121.3 | 49 | 61.1 | 84.7 | 117.5 | |

| Weight of Machine | ton | 4 | 6 | 6.5 | 8 | 10 | 4.5 | 6.5 | 7 | 8 | 10.5 | 7.5 | 8 | 9 | 11.5 | |

* All models can be upgraded to hybrid or fully electric type by servo motor control.