This series is specified for producing particular containers that are fully sealed, light resistive, heat resistive, anti-bacterial, durable, anti-static, corrosion resistive, non-toxic…etc.

ADVANTAGES

1. It provides better quality monolayer extrusion coatings over a wider variety of widths and line speeds.

2. The potential to save on the amount of premium resins by filling with lower cost materiais.

3. The possibility to malke multi-layer, multi-functional structures in a single pass.

Features

Double layers :

1. Combination of Layers A: Virgin - Recycled

Application :

● Cost saving due to less virgin material using.

● Eco-friendly due to usage of recycled material.

● Harder and stronger containers due to double layer structure.

2. Combination of Layers B: Natural - Colored

Application :

● Cost saving due to less additives using.

● Great application for sensitive filling (such as milk) that should not be in contact directly with material with color additives.

3 layers :

1. Combination of Layers A: HDPE/PP – Recycled – HDPE/PP

Application :

● Eco-friendly due to usage of recycled material.

● Harder and stronger containers due to double layer structure.

2. Combination of Layers B: Virgin HDPE/PP – Recycled with carbon black – Virgin HDPE/PP

Application :

● Great application for sensitive products such as yogurt.

● Improves storage life.

3. Combination of Layers C: Nylon –Adhesive – HDPE/PP

Application :

● Great application for chemical pesticides and similar hazardous chemicals, corrosive products etc.

● Improve gas barrier properties.

4 layers :

1. Combination of Layers A: Nylon –Adhesive – Regrind/recycled- HDPE/PP

Application :

● Great application for chemical pesticides and similar hazardous chemicals, corrosive products etc.

● Improve gas barrier properties.

● Eco-friendly due to usage of recycled material.

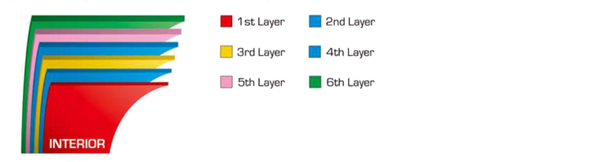

6 layers :

1. Combination of Layers A: HDPE/PP – Adhesive – Barrier resin – Adhesive – Regrind – HDPE/PP

Application :

● Much higher storage life and aroma retention.

● Great application for automobile products.