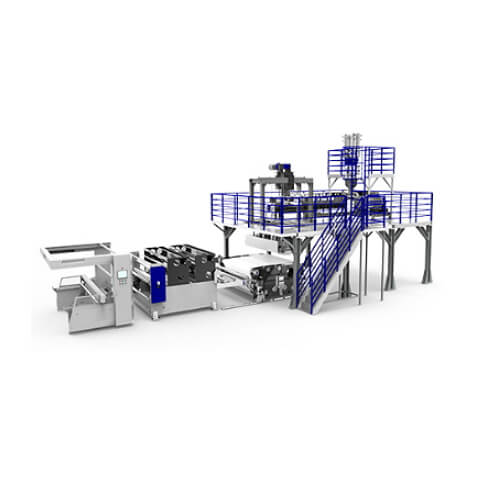

Meltblown Non-Woven Fabric Production Lines - MB1600

Categories : Melt Blown Fabric Making Machine

Meltblown Non-Woven Fabric Production Lines - MB1600 Using extremely fine fibers to produce meltblown Non-Woven Fabric

Corona Electrostatic Treater

Categories : Melt Blown Fabric Making Machine

This CORONA ELECTROSTATIC TREATER is used to turn materials such as melt-blown fabric (face mask sheet),non-woven fabric (non-woven sheet) and polymers into electrets. The equipment includes a high...

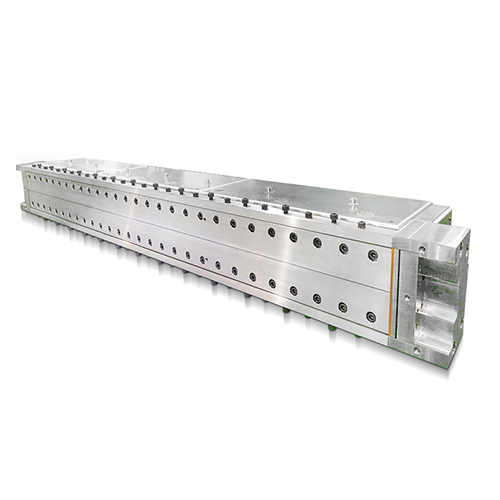

Extrusion Dies Foam Sheet

Categories : Melt Blown Fabric Making Machine

Plate sheets composite lightweight preferred. Fast tuning into foaming materials with desired thickness through flow adjustment and precision heating area. SUITABLE AVAILABLE FOAMING POLYMER INCLUD...

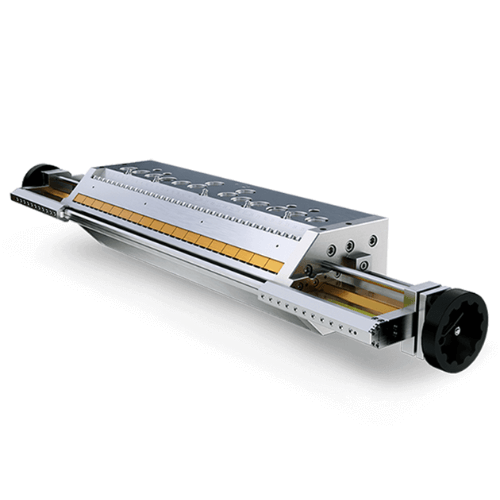

Extrusion Dies MELTBLOWN DIES

Categories : Melt Blown Fabric Making Machine

SUITABLE AVAILABLE FOR POLYMERS INCLUDING PET And PP High processing precision. Internal heating with heating rod, external heating with heating board, temperature control by heating oil cycle to e...

PLATE / SHEET

Categories : Melt Blown Fabric Making Machine

Composed of simple structure and segment with diversified adjustment methods. Suitable for single and multi- layers configuration in terms of customer ‘s polymer property. SUITABLE AVAILABLE ...

Extrusion Dies Thin Sheet

Categories : Melt Blown Fabric Making Machine

Multi-layer composite materials design, excellent polishing technique, compliant with super mirror requirements up to Ra 0.03 SUITABLE AVAILABLE FOR POLYMERS INCLUDING BOPA, BOPET, BOPI, BOPP, BOPS

PP Meltblown Nonwoven Lines

Categories : Melt Blown Fabric Making Machine

The JC-MB Series incorporates PLASCO signature innovation, quality, and efficiency to produce medical-grade nonwoven polypropylene fabric. This technologically-advanced fabric, possesing unique fil...