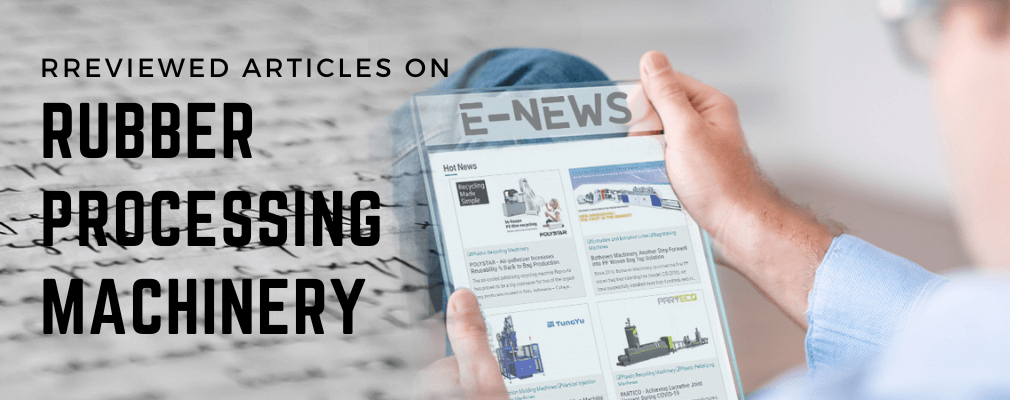

Twin Type Screws With Extrusion Strainer

Categories : Rubber Extrusion Lines

PRODUCT INTRODUCTION Basically,rubber material is very easy to be mixed with many impurities during mixing processes.No doubt,because of this harmful factor,it can easily cause the follow-up produc...

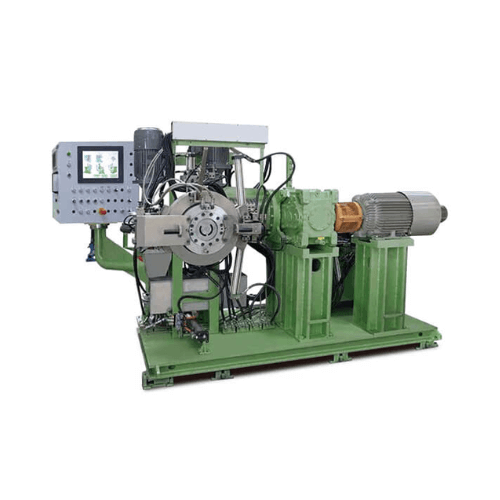

Twin Screw Roller (TSR) Head Extruder

Categories : Rubber Extrusion Lines

MACHINE FUNCTION: The Twin Taper Screws Roller Head Extruder consists of two tapered screws and two rollers,The machine is normally applied for processing to a dispersion kneader or an intensive mi...

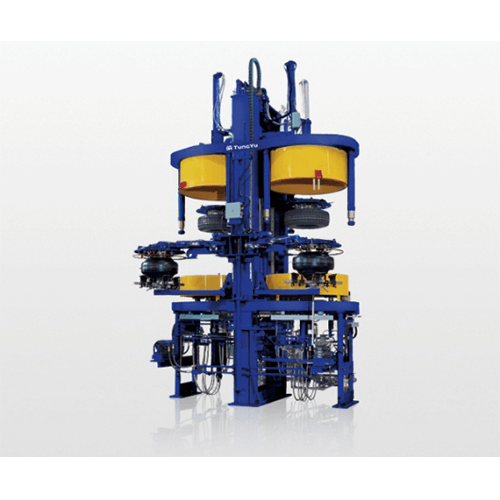

51 Inch Tire Curing Press

Categories : Hydraulic Tire Curing

• Equipped with servo motor for energy saving, product quality stabilization and operation efficiency. • Accurate loader and unloader mechanism with bumper function for excellent alignmen...

Rotocure with CE Certificate / Continuous Vulcanizing

Categories : Hydraulic Tire Curing

Rotocure - continuous vulcanizing press, suitable for production of wide range of rubber sheets with specific surface texture or shape requirements.

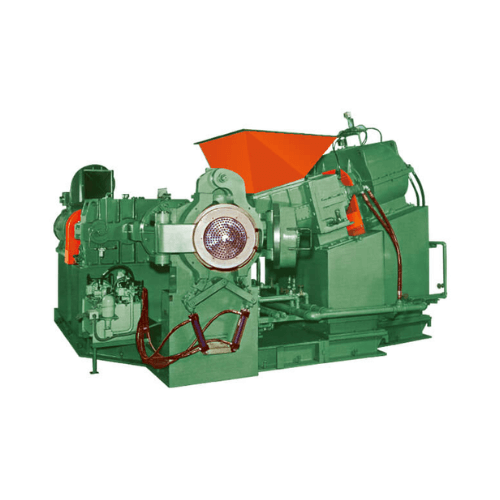

42 Inch Tire Curing Press

Categories : Hydraulic Tire Curing

•The mainframe consists of the steel plate and U type steel welding with high-temperature treatment. After matching, release stress to improve the machine life cycle. • Return oil with fi...

Rear Transfer Injection Type Rubber Compression Molding Machine

Categories : Hydraulic Tire Curing

Special for nylon cord retread tire with high temperature or second curing for tire with low temperature. With loading and unloading platform to save labor handling.