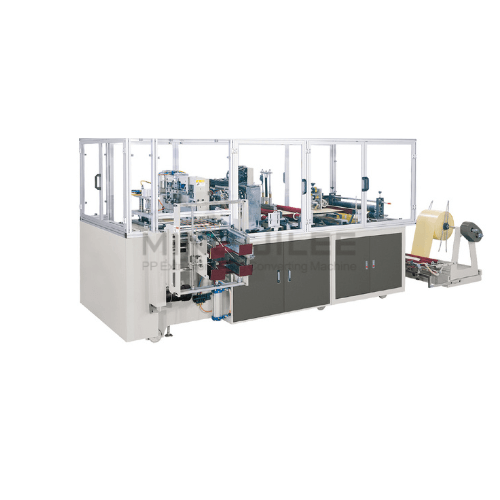

Fully Automatic Clear Folder (L Shape Folder) Machine

Categories : Sheet Protector Machine

Fully Automatic Clear Folder (L Shape Folder) Machine

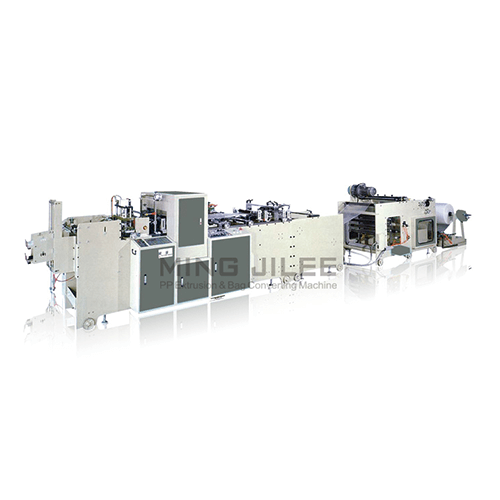

Twin Line Sheet Protector Machine ( Blown Film)

Categories : Sheet Protector Machine

MGA-17A-700DSP This machine is designed especially for all kinds of data bag (sheet protector) from the plastic feed material (CPP or IPP) to the finished product. The twin line machine can be oper...

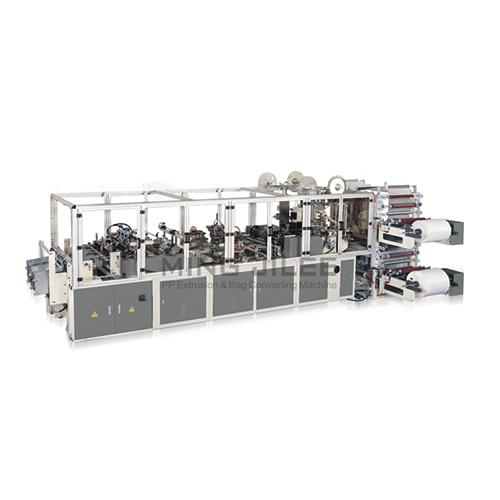

Bag Making Machine for Stationary Bags

Categories : Sheet Protector Machine

Inner Sleeves Making Machine Book Cover Prep Machine Automatic Inline Assembly Machine Option Automatic Inline Packaging Machine Twin Line File Sleeves & L-file making Machine FCV /...

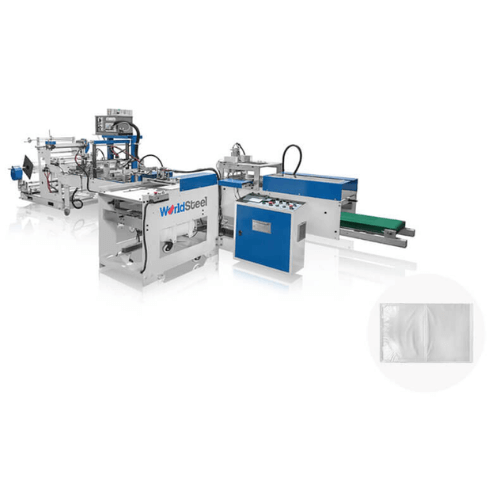

Automatic Display Book Machine With Packing System

Categories : Sheet Protector Machine

Most of the clear display books with sheet protectors require extra manpower for bonding, welding, dotting and packing. In response to Industry 4.0, automation manufacturing is essential and implem...