Bottle Recycling Lines

Bottle recycling lines are designed to process PET and HDPE bottles through label removal, sorting, crushing, hot washing, and drying. These systems convert post-consumer bottles into clean, high-quality flakes suitable for food-grade, fiber, strapping, and injection reuse.

PRM-Taiwan features two main solutions: Bottle-to-bottle recycling machines meet FDA and EFSA food-grade rPET standards, integrating hot washing, drying, and decontamination modules for direct bottle-to-bottle reuse; PET bottle recycling lines include label removers, float-sink separators, washers, and dewatering systems, ideal for flake production and raw material recovery operations.

RAS UP 800

Categories : Bottle Recycling Lines

FIMIC’s latest innovations are aimed to address the current challenges in the plastics recycling industry. RAS 800 is the new addition to the automatic self-cleaning melt filters models produ...

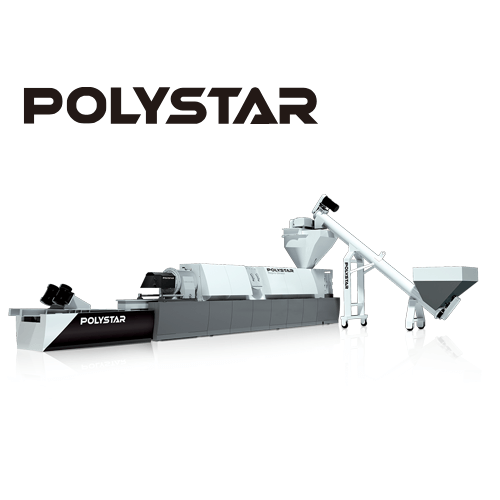

Force Side Feeding Plastic Recycling Machine (RECO Series)

Categories : Bottle Recycling Lines

Increasingly Feeding The force side feeding device creates a very stable feeding flow. With stable feeding, the main screw is always fully loaded with materials, which ensures the highest output pe...

Force Hopper Feeding Plastic Recycling Machine (H Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatme...

Two Stage Hopper Feeding Plastic Recycling Machine (Hi Series)

Categories : Bottle Recycling Lines

Economically Selection A valuable selection for clean materials, without pre-heating section for feeding device, this reduces the power consumption. The axle made by special steel with heat treatme...

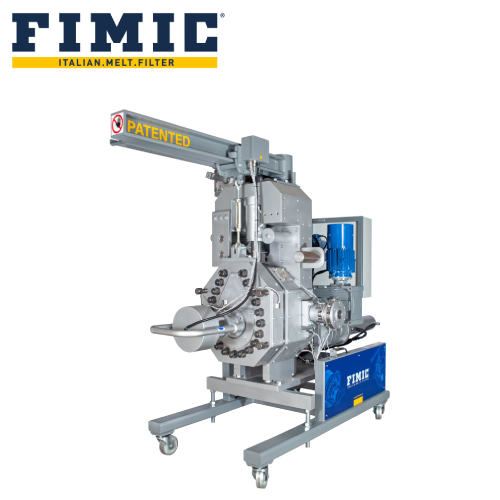

Automatic self-cleaning screen changer - RAS

Categories : Bottle Recycling Lines

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve....

Bottle to Bottle Recycling Plant

Categories : Bottle Recycling Lines

Bottle to Bottle Recycling Plant

EXCLUSIVE MELT FILTER- GEM

Categories : Bottle Recycling Lines

Differently from RAS, this model reaches a greater filtering surface due to the presence of two filtering meshes towards which all the melt is directed, alongside two scrapers and independent disch...

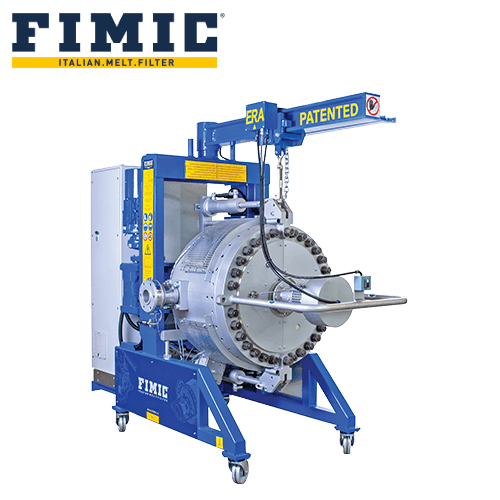

Automatic DOUBLE FILTER- ERA

Categories : Bottle Recycling Lines

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machin...

Hard Plastic Recycling Machine: Repro-Direct

Categories : Bottle Recycling Lines

● The Perfect Solution for recycling plastic films waste/ regrind/ granules ● Crusher and conveyor can be added and combined into a complete recycling line

PET Bottle Recycling Washing System

Categories : PET Bottle Recycling Line

PET bottles bales to PET flakes

AUTOMATIC MELT FILTER- TEN

Categories : Bottle Recycling Lines

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the req...

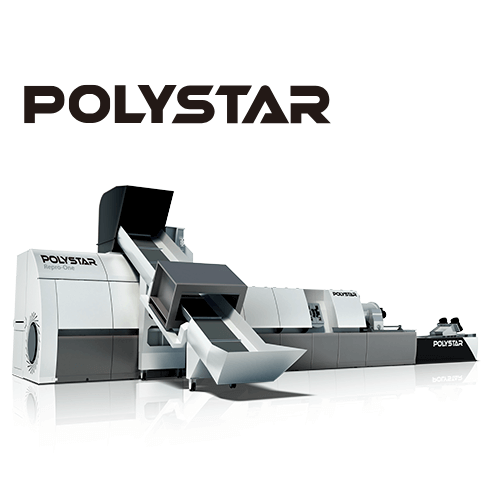

Shredder Integrated Recycling Machine: Repro-one

Categories : Bottle Recycling Lines

One step technology for PP raffia, woven and PE/PP Film waste

Automatic Melt Filter - RAS+REF

Categories : Bottle Recycling Lines

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in sc...

HDPE High Speed Mono Layer Blown Film Machine

Categories : PET Bottle Recycling Line

Application: T-shirt bags, shopping bags, garbage bags, mattress cover, laundry bags etc. Suitable material: HDPE / MDPE / HDPE+LLDPE Film layer: 1 layer Screw L/D ratio:&nb...